39

EN

Furnaces

7.12 Servicing the gas valve

I

The burner head, electrode, and gas valve on the late model 79 series furnaces are individually accessible.

To service these same components on the late model 85 and 89 series, remove the complete assembly.

Perform the steps in Accessing the furnace components (on page 30) before proceeding with service.

Testing the Ohms

40

Gas Valve

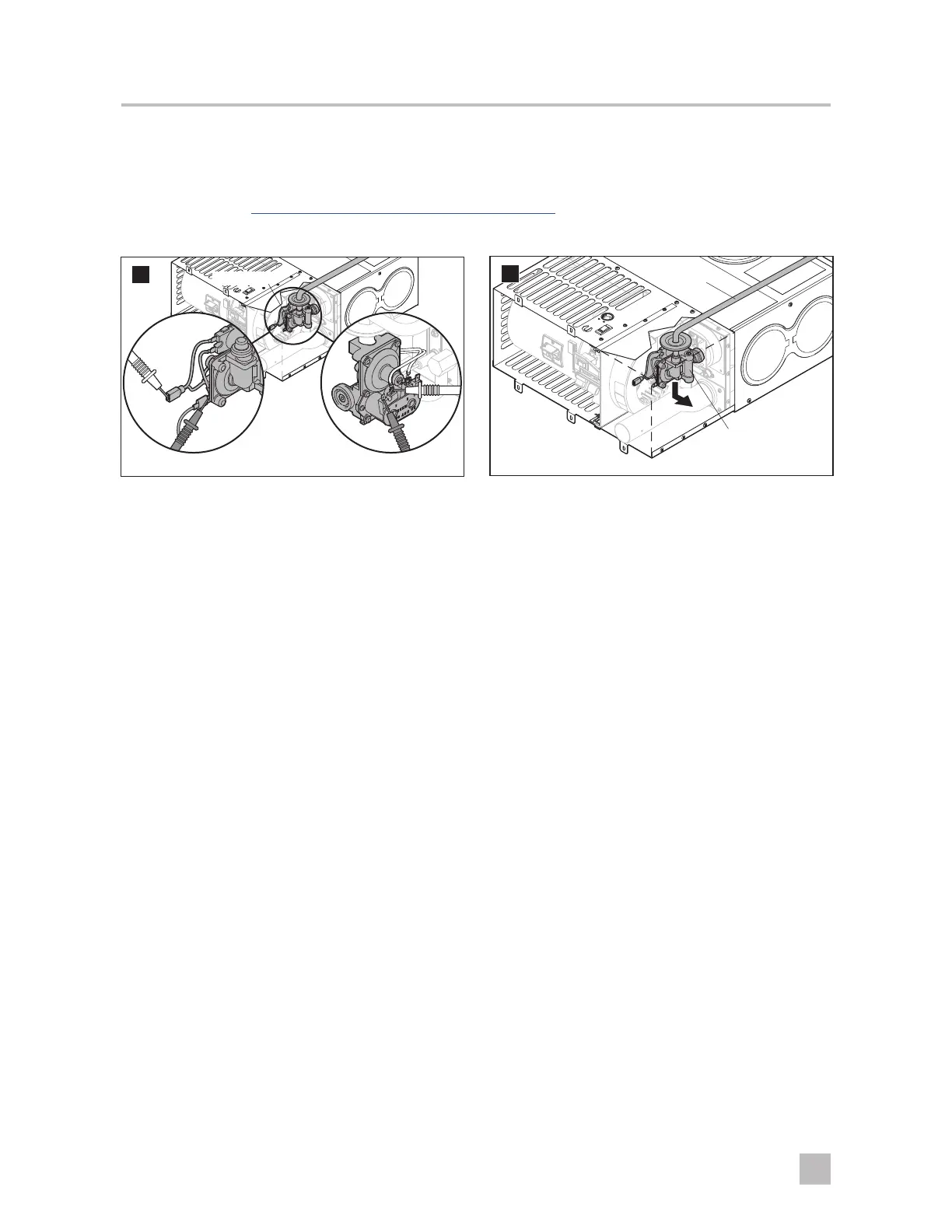

(Newer Model) (Older Model)

Older Models

➤ Using a Volt-Ohm Meter, measure the resistance on

the solenoid coil:

– Make sure the coils are isolated and

disconnected from the power and ground

sources.

– Place one meter lead on each coil terminal on

one of the solenoids.

– Confirm the resistance is between 30 Ohms

and 50 Ohms.

– Repeat the steps for the second solenoid.

Newer Models

➤ Using a Volt-Ohm Meter, measure the resistance on

the solenoid coil:

– Disconnect the positive terminal from the

power source.

– Disconnect the negative terminal from the

ground source.

– Make sure the coils are not isolated.

– Place one meter lead on the positive terminal.

– Place one lead on the negative terminal.

– Confirm the resistance is between 15 Ohms

and 25 Ohms.

Adjust the Gas Supply Line

41

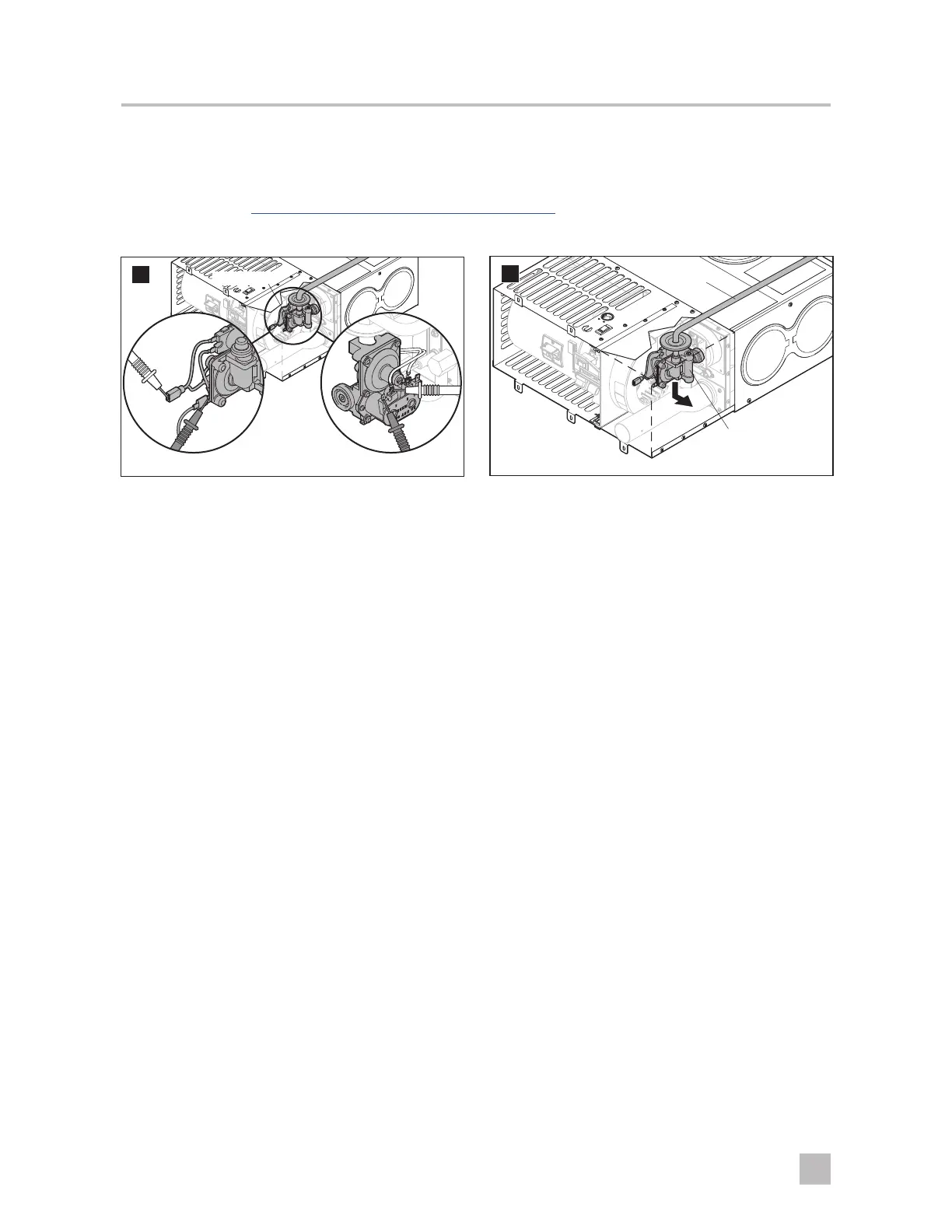

Gas Valve

Gas Line

I

Adjustment of the gas supply line is a solution

when the furnace lights and goes out

repeatedly, but does not enter lockout. It can

also occur during a pre-delivery inspection

(PDI) or the first time the unit is used in colder

weather. Mainly, this solution is necessary for

the AF Series furnaces.

➤ Locate the gas supply line for the furnace.

➤ When the furnace ignites, gently apply pressure to

the supply line to move it down and to the right in

very small increments.

➤ Continue to adjust the supply line until the furnace

remains lit aer ignition.

Loading...

Loading...