20

INSTALLATION

F. Connecting The Gas

FIRE OR EXPLOSION HAZ ARD. Failure to obey the following warnings could result in property damage, serious

injury, or death:

• Install gas connections in compliance with the applicable supplemental directives listed in this manual. Refer to

“C. Supplemental Directives” on page 2.

• NEVER use an open flame to check for gas leaks. Use a commercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in these instructions.

• Should the gas supply fail to shut off or if overheating occurs, shut off the gas valve to the Furnace before shutting off the

electrical supply.

• Do NOT put sealing compound on flare fittings.

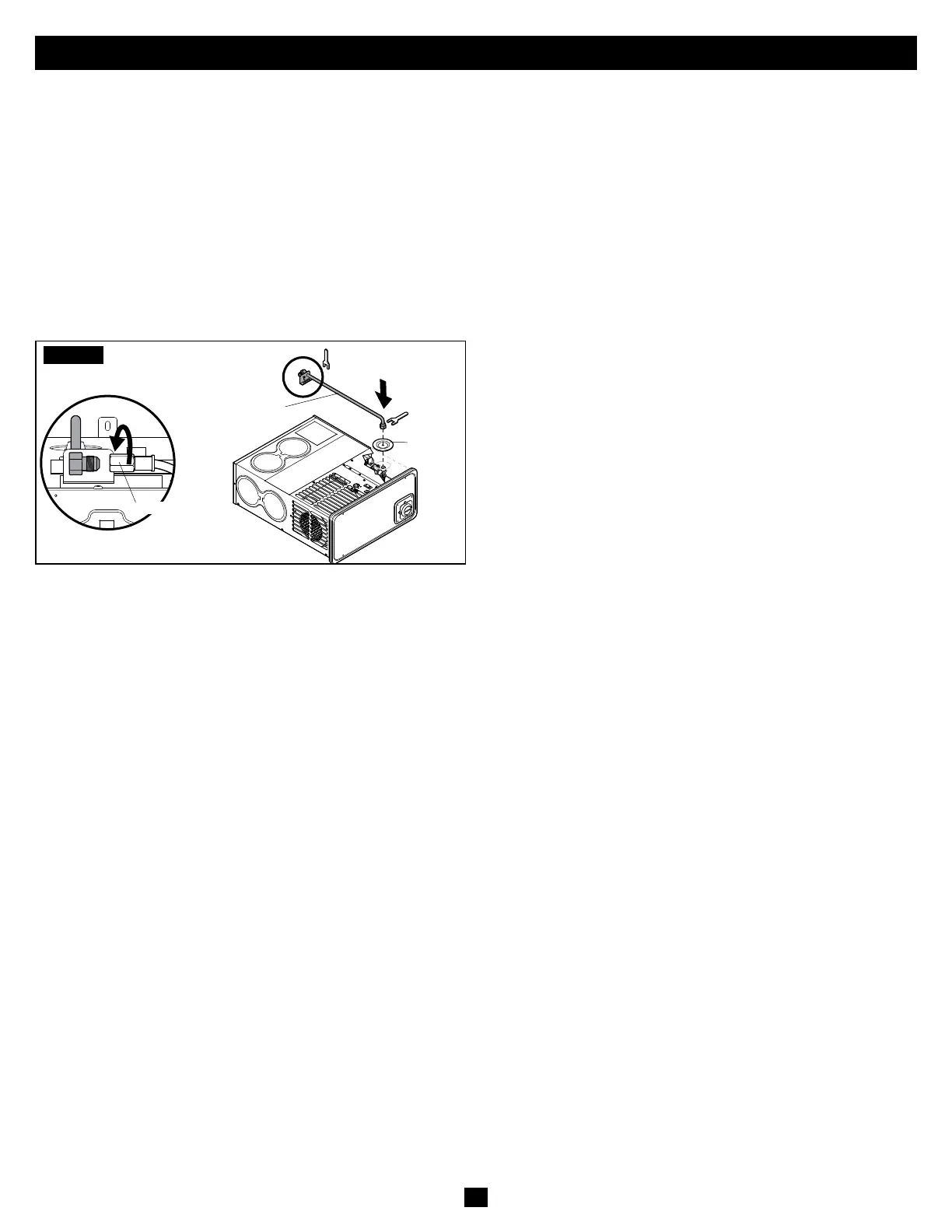

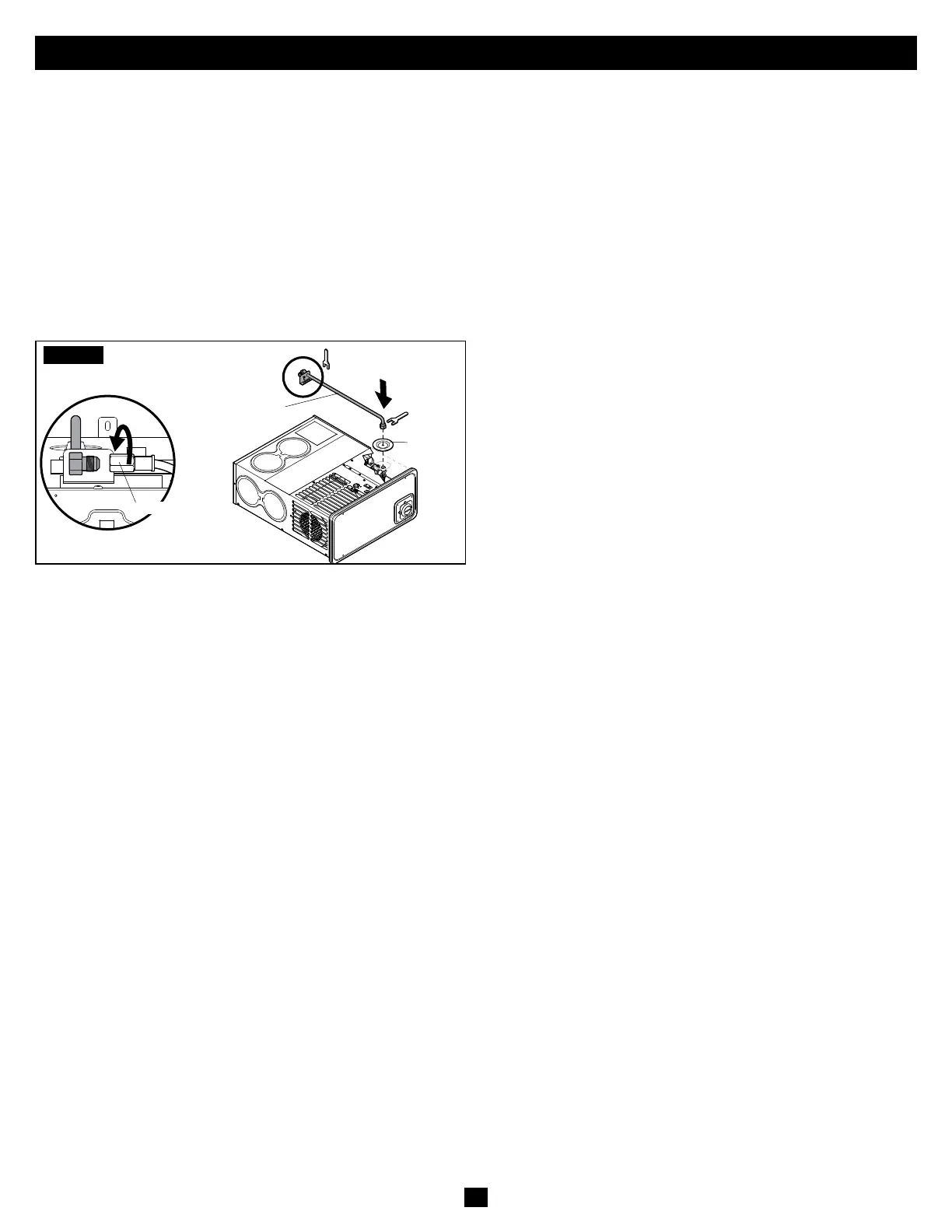

FIG.1

Extended

Manifold

(Rear)

Gas Connection

Grommet

Plug

An extended manifold is used in this example; however,

the use of tubing or other variations to connect the gas is

acceptable.

• Treat all male pipe threads, other than flare fittings, with a

sealing compound resistant to a chemical reaction with LP

gas.

• Remove the grommet plug from the Furnace and install on

the gas line.

• Insert the gas line through the hole in the top of the casing.

• Connect the gas line to the fitting located on the valve. If

the Furnace is supplied with an extended manifold,

connect the gas line at the rear of the Furnace.

• Reinstall the grommet plug on the casing, as it is a required

air seal. DO NOT CUT.

• Use two wrenches to hold the valve and flare nut, and

tighten the flare nut over the gas line.

• Torque the fitting to 20–22 . lbs. Do NOT twist the valve

out of position when tightening the gas line.

For DFLA35 and DFLA40 models only, a gas conversion kit

is included with your Furnace. To convert the Furnace gas

type, proceed to “G. Converting The Furnace Gas Type” on

page 21.

LP Gas Pressure Test

Read BEFORE proceeding:

• Test all piping systems BEFORE connecting the

Furnace.

• Disconnect the Furnace and any individual shut-off

valves from the gas supply piping system when

pressure testing the system at pressures of more than

1/2" PSI.

• If local codes allow the use of a flexible gas appliance

connector, do NOT use a connector which has

previously serviced another gas appliance.

• For gas conversions only, a 1/8" NPT plug is provided

upstream of the gas connections for checking the gas

pressure.

• Perform an air pressure test on the piping system. The test

must maintain an air pressure of a least 6" of mercury or

3 PSI for at least 10 minutes.

• Adjust the piping system to maintain the minimum gas

supply pressure listed on the rating plate, when all

appliances are in operation.

• Test gas connections for leakage with a commercially

available soap solution made specifically for the detection

of leaks.

Loading...

Loading...