A Series Diesel Engine Air System 101

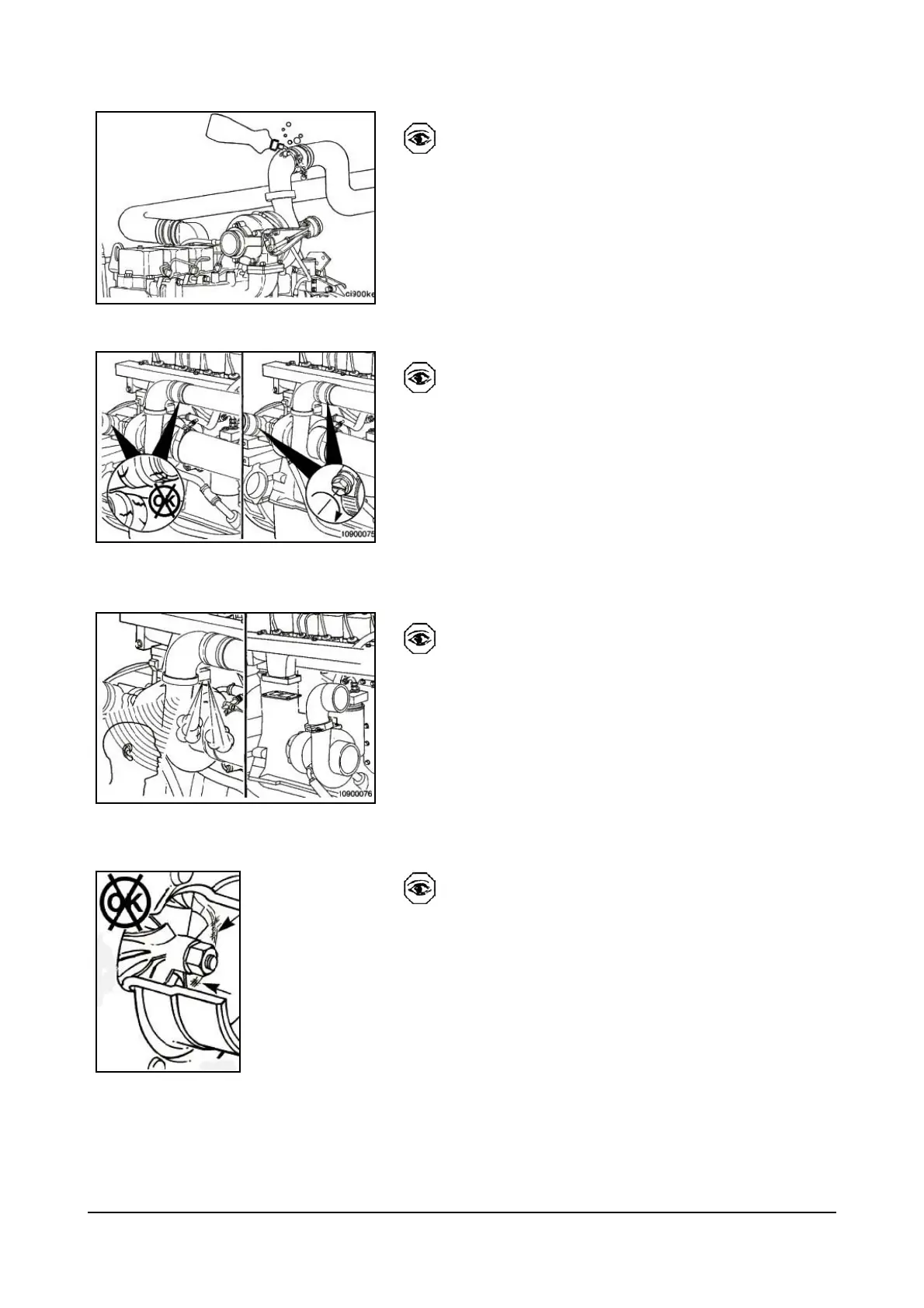

In addition to the visual inspection for cracks and loose

fittings, liquid soap can be applied to the crossover

tube, connections and the manifold cover sealing

surfaces to find the leaks.

The leaks will create bubbles that are easier to detect.

Measurement of manifold pressure is described in this

Section.

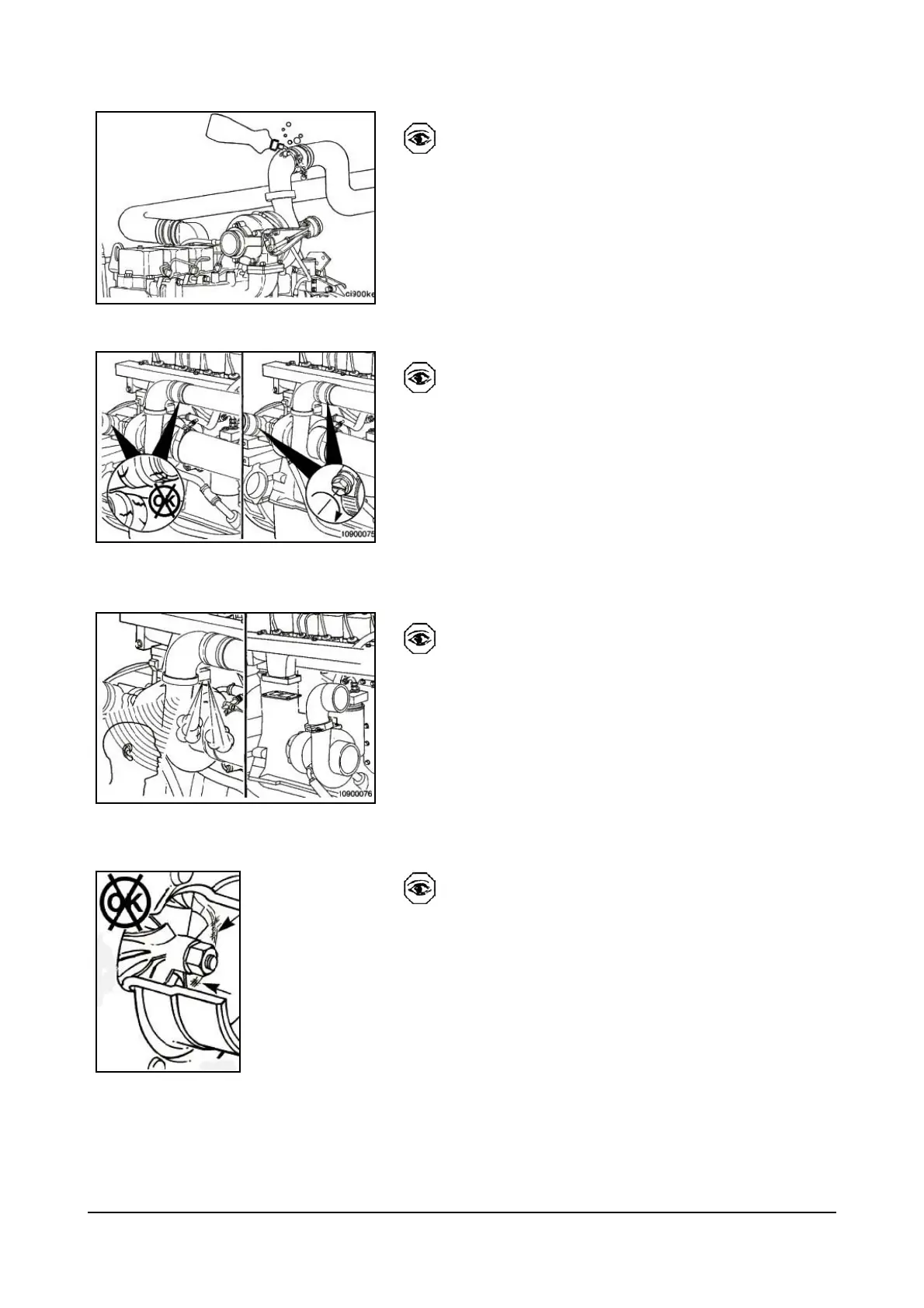

Exhaust Leaks (Turbocharged

Engines)

Inspect for exhaust leaks at the exhaust manifold and

turbocharger, gasket leaks, or exhaust pipe

restrictions.

Leaks or restrictions will cause the turbine and impeller

to operate at a lower speed and reduce the amount of

air being forced into the cylinders. Again, the symptom

will be excess smoke, low manifold pressure and low

power.

Exhaust leaks can usually be detected audibly or

visually by a discoloration caused by the escaping hot

gases.

Don’t overlook exhaust restrictions as a cause of low

power. If the exhaust gasses can not flow freely, the

turbocharger will not operate efficiently.

Malfunctioning Turbocharger

Failure of the internal components of the turbocharger

can reduce its effectiveness and also cause excess

smoke and low power. A bearing failure can produce

friction which will slow the speed of the rotor assembly.

Failed bearings can also allow the blades of the rotor

assembly to rub the housings, thus reducing the rotor

assembly speed.

Loading...

Loading...