G424F(FE) Service Manual Chapter 3. Engine Mechanical System 80

Important

• If the lash is out of the specification, which is

0.015 – 0.042 mm (intake) and 0.038 – 0.072

mm (exhaust), ream the guide to install an

oversize valve.

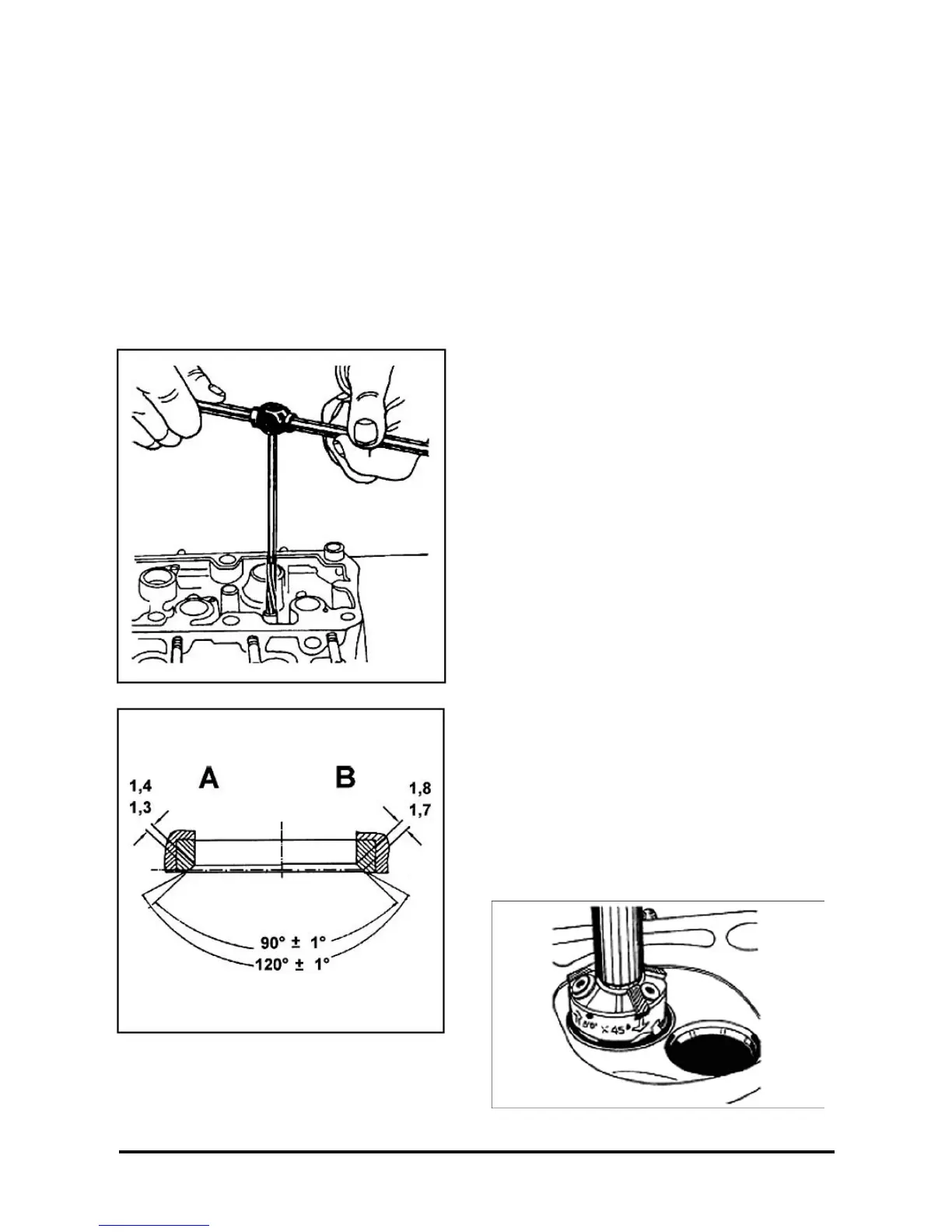

• Valve seat for:

Concentricity between maximum and minimum

readings, which should be 0.05 mm (0.002 in.)

Width, which should be 1.3 – 1.4 mm (intake A) and

1.7 – 1.8 mm (exhaust B)

Important

• If necessary use a 45° ± 3° Valves for corrosion.

Corroded valves, once not excessively worn,

can be refaced by special equipment, as

follows:

Reface them until obtaining a 92 ° ± 15° angle.

The face angle can also be considered

regarding the valve head, which should be 44°.

Installation

Install or connect

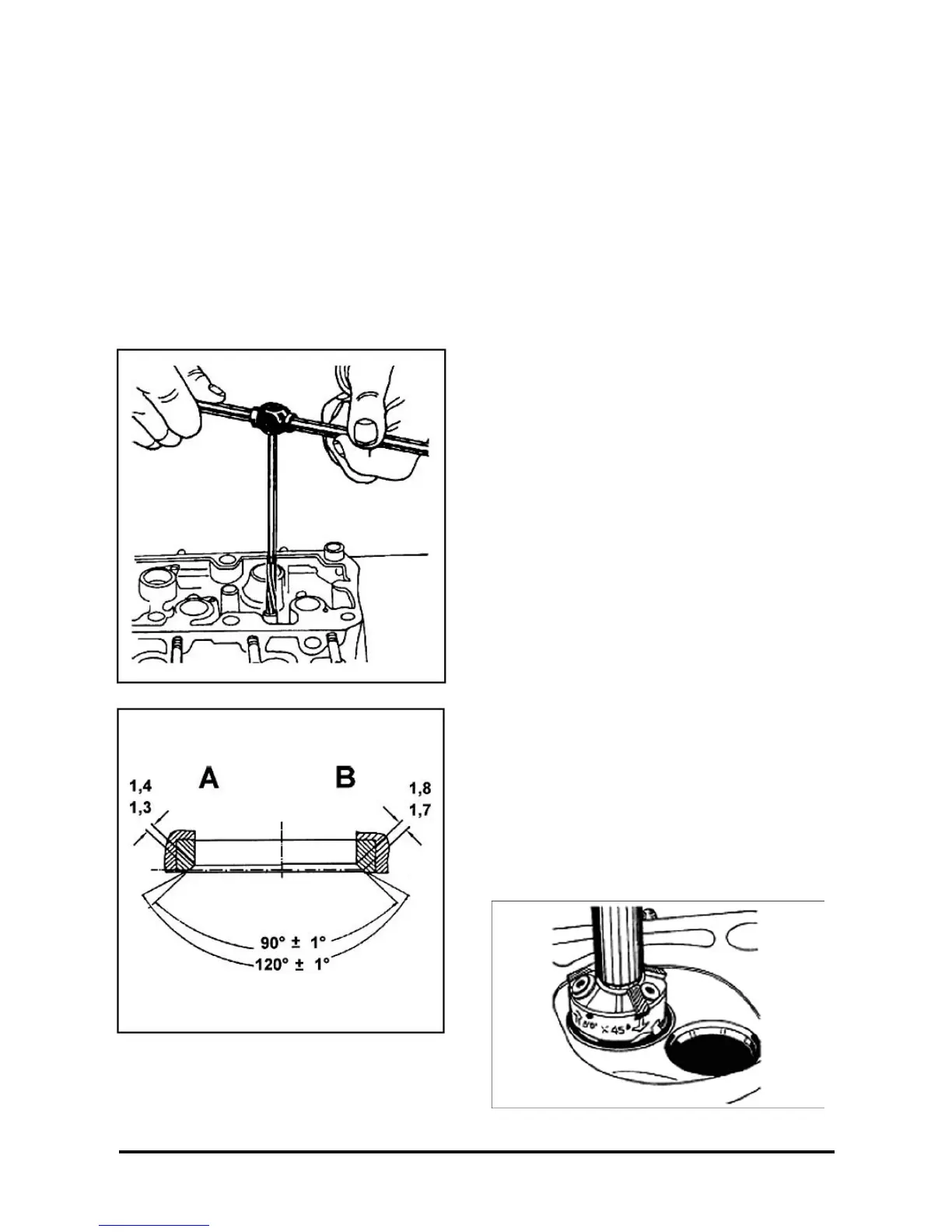

1. Valve seal, with the aid of tool KM-352.

2. Spring and spring plate.

3. Valve lock, with the aid of valve spring

compressor.

4. Exhaust manifold with a new gasket to the

cylinder head and use new nuts, without

tightening.

5. With a 13-mm socket wrench, extension and

torque wrench, tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.)

6. Intake manifold with a new gasket to the cylinder

head and use new nuts, without tightening.

7. With a 13-mm socket wrench, extension and

torque wrench, tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16. lb·ft.)

8. Camshaft case assembly; see “Camshaft Case

Assembly – Installation”, in this section.

Loading...

Loading...