WILDEN PUMP & ENGINEERING, LLC 18 WIL-12350-E-02

REASSEMBLY HINTS & TIPS

Description of Part H1500 HS Stainless Steel H1500 HS Ductile Iron

Inner Piston Bolts* 58.3 N•m (43 ft-lb) 58.3 N•m (43 ft-lb)

Outer Piston 140 N•m (103 ft-lb) 140 N•m (103 ft-lb)

Air Valve Bolts 9.5 N•m (84.1 in-lb) 9.5 N•m (84.1 in-lb)

Inlet/Discharge Manifold Bolts 17.6 N•m (13 ft-lb) 163 N•m (120 ft-lb)

Center Section Cover Bolts 54.0 N•m (40 ft-lb) 54.0 N•m (40 ft-lb)

Air Chamber Bolts* 88.1 N•m (65 ft-lb) 163 N•m (120 ft-lb)

Liquid Chamber Bolts 58.3 N•m (43 ft-lb) 163 N•m (120 ft-lb)

REASSEMBLY:

Upon performing applicable maintenance to the air distribution

system, the pump can now be reassembled. Please refer to the

disassembly instructions for photos and parts placement. To reas-

semble the pump, follow the disassembly instructions in reverse

order. The air distribution system needs to be assembled first, then

the diaphragms and finally the wetted path. The following tips will

assist in the assembly process:

• Lubricate air valve bore, center section shaft and pilot spool

bore with NLGI grade 2 white EP bearing grease or equivalent.

• Clean the inside of the center section shaft bore to ensure no

damage is done to new shaft seals.

• A small amount of NLGI grade 2 white EP bearing grease can be

applied to the muer and air valve gaskets to locate gaskets

during assembly.

• Make sure that the exhaust port on the muer plate is cen-

tered between the two exhaust ports on the center section.

• Stainless bolts should be lubed to reduce the possibility of seiz-

ing during tightening.

• Use a mallet to tap lightly on the large clamp bands to seat the

diaphragm before tightening.

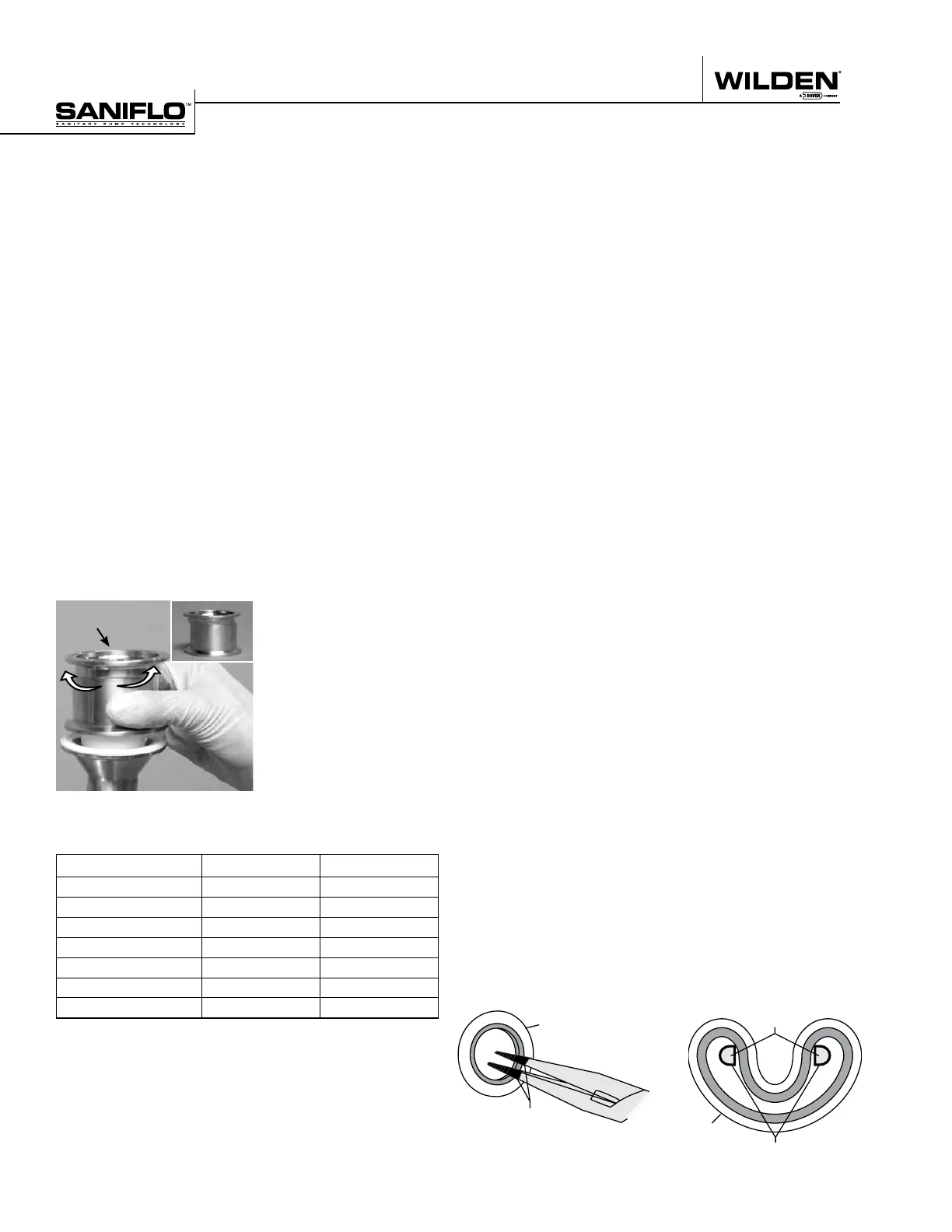

NOTE: To ensure proper

alignment during reassembly

of manifold/liquid chamber

interface, turn off-set portion

of valve housing to the left or

to the right. This procedure

works for the inlet mani-

fold and discharge manifold

connections.

MAXIMUM TORQUE SPECIFICATIONS

OFF-SET

VALVE

HOUSING

TWIST

SHAFT SEAL INSTALLATION:

PRE-INSTALLATION:

Once all of the old seals have been removed, the inside of the

bushing should be cleaned to ensure no debris is left that may

cause premature damage to the new seals.

INSTALLATION:

The following tools can be used to aid in the installation of the

new seals:

Needle-Nose Pliers | Phillips Screwdriver | Electrical Tape

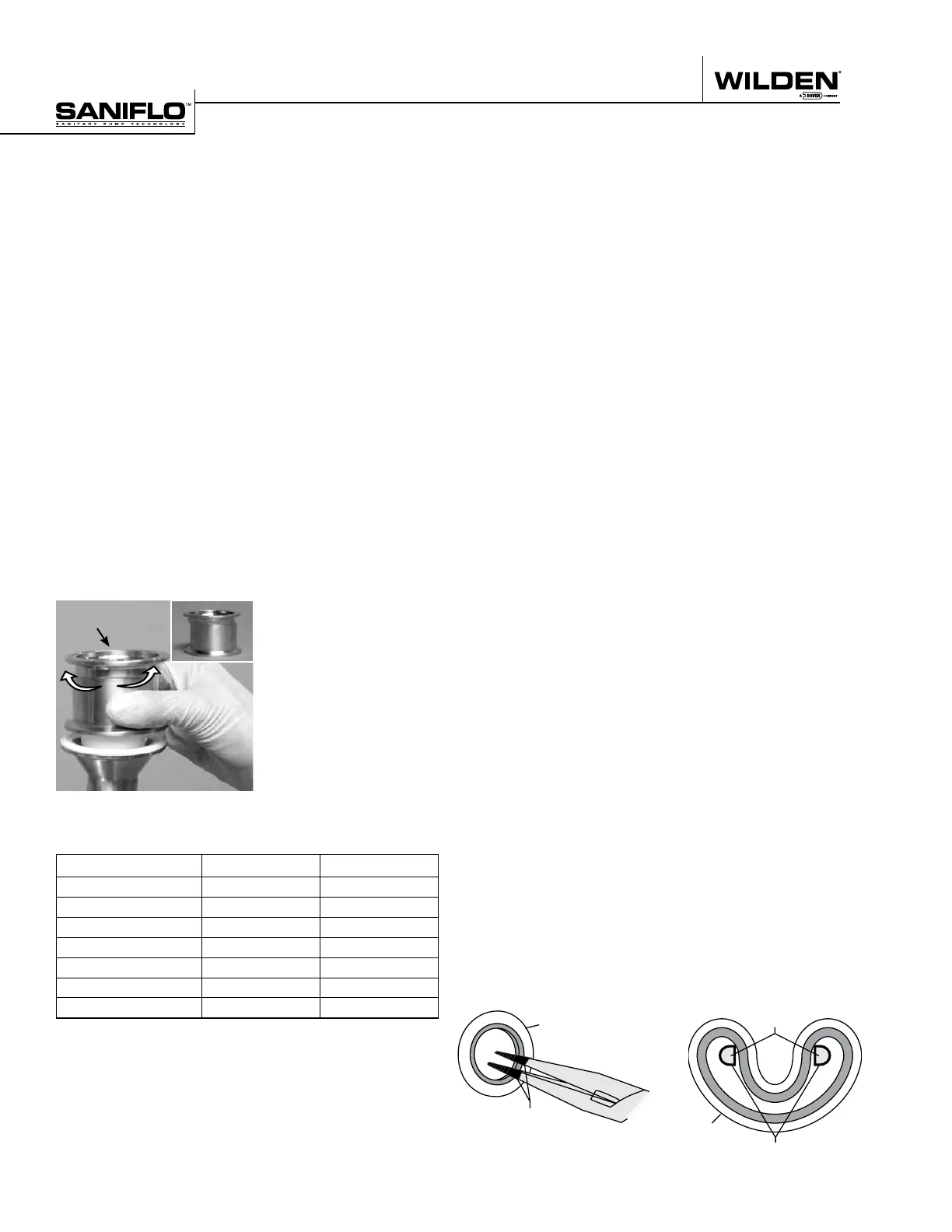

• Wrap electrical tape around each leg of the needle-nose pliers

(heat shrink tubing may also be used). This is done to prevent

damaging the inside surface of the new seal.

• With a new seal in hand, place the two legs of the needle nose

pliers inside the seal ring. (See Figure A.)

• Open the pliers as wide as the seal diameter will allow, then

with two ngers pull down on the top portion of the seal to

form kidney bean shape. (See Figure B.)

• Lightly clamp the pliers together to hold the seal into the kid-

ney shape. Be sure to pull the seal into as tight of a kidney shape

as possible, this will allow the seal to travel down the bushing

bore with greater ease.

• With the seal clamped in the pliers, insert the seal into the bush-

ing bore and position the bottom of the seal into the correct

groove. Once the bottom of the seal is seated in the groove,

release the clamp pressure on the pliers. This will allow the seal

to partially snap back to its original shape.

• After the pliers are removed, you will notice a slight bump in

the seal shape. Before the seal can be properly resized, the

bump in the seal should be removed as much as possible. This

can be done with either the Phillips screwdriver or your nger.

With either the side of the screwdriver or your nger, apply

light pressure to the peak of the bump. This pressure will cause

the bump to be almost completely eliminated.

• Lubricate the edge of the shaft with NLGI grade 2 white EP

bearing grease.

• Slowly insert the center shaft with a rotating motion.

• This will complete the resizing of the seal.

• Perform these steps for the remaining seals.

Figure A

SHAFT SEAL

TAPE

Figure B

SHAFT SEAL

TAPE

NEEDLE NOSE

PLIERS

*Use #242 removable Loctite® on fastener threads.

Loading...

Loading...