12 DR

®

K10 RAPIDFIRE™ LOG SPLITTER

Chapter 4: Maintaining the DR K10 RAPIDFIRE LOG SPLITTER

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this manual for

proper maintenance procedures.

Regular Maintenance Checklist

PROCEDURE BEFORE EACH

USE

EVERY 5

HOURS

EVERY 25

HOURS

Check General Equipment Condition

▲

Perform Rail Maintenance

▲

Check Belt

▲

Check the condition of the electrical cord.

▲

Grease Rack

▲

Clean Motor Exterior and Cooling Fins

▲

Lubrication

All Bearings of your Splitter are sealed units and should have sufficient lubricant

to last the life of your machine with normal use. Perform machine lubrication

per the following instructions.

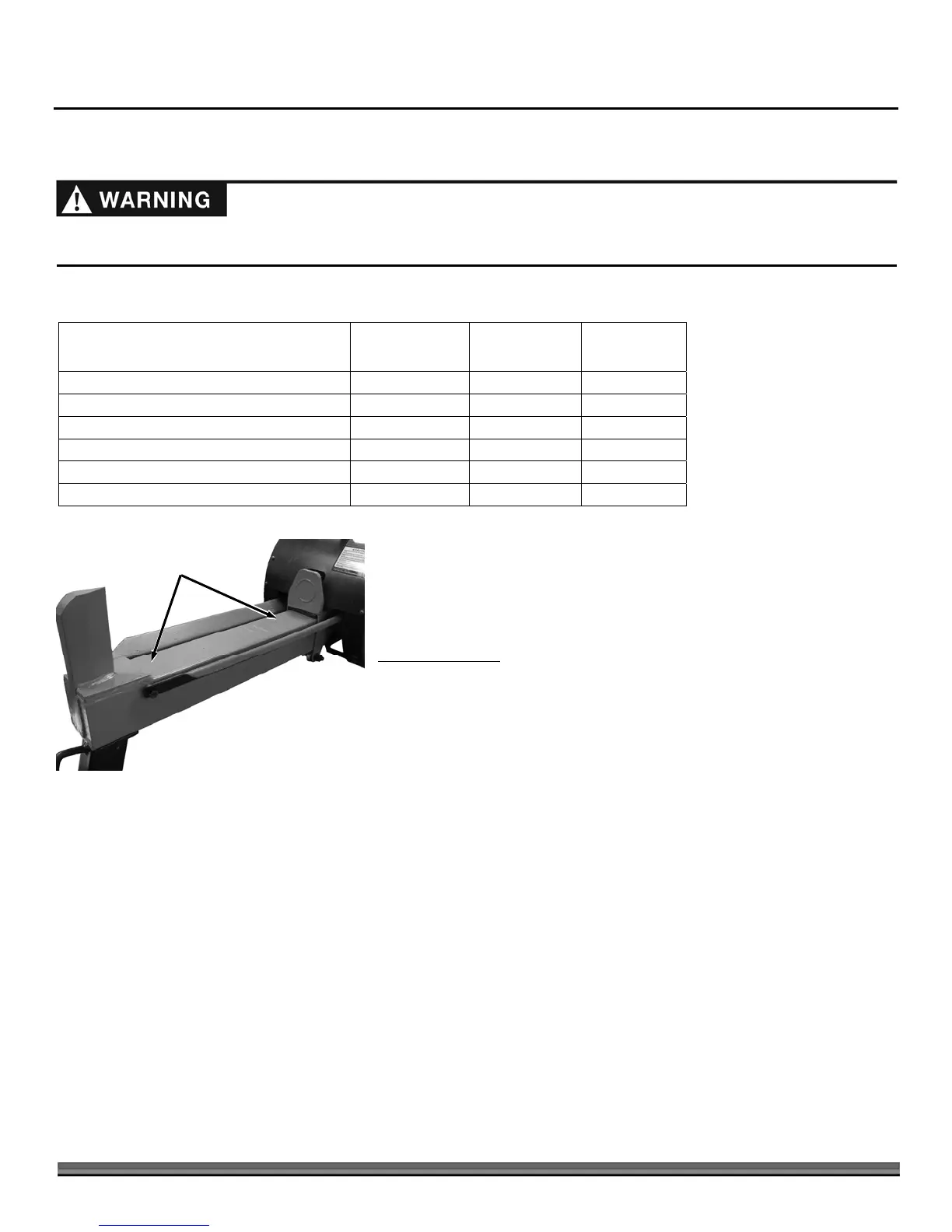

Rail Maintenance

Between each use of the LOG SPLITTER, we recommend removing any debris

caught on the Rail or Ram and applying a rust preventative (Fluid Film or

equivalent) to any bare metal areas on the top of the Rail (Figure 11). This will

assure the smoothest return action of the Ram.

Figure 11

Top of Rail

Before performing any maintenance procedure or inspection, stop the motor, unplug the power cord and wait five (5) minutes to

allow all parts to cool.

Loading...

Loading...