CONTACT US AT www.DRpower.com 21

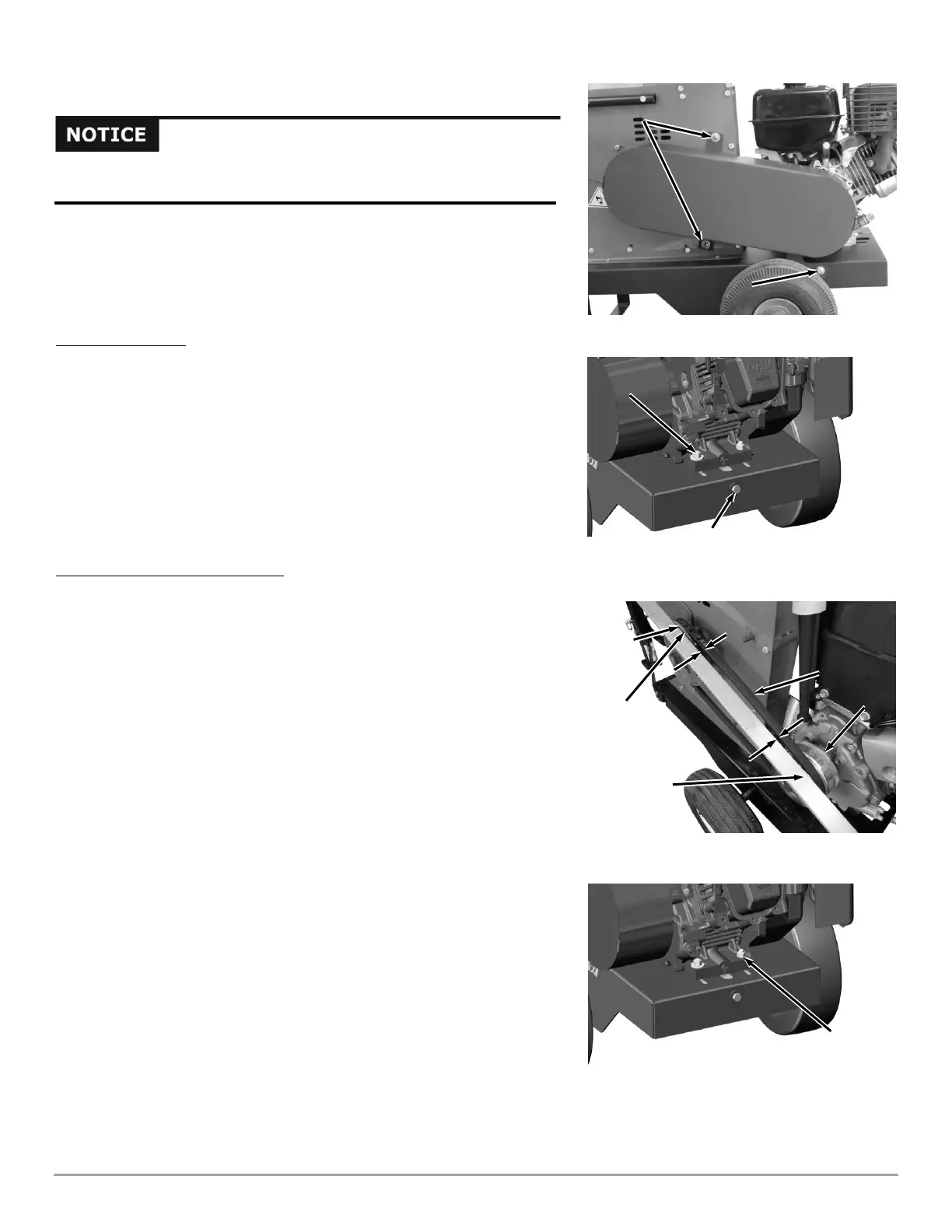

Belt Tensioner

Adjusting Bolt

Removing, Replacing and Adjusting the Drive Belt

Tools Needed:

Tape Measure

Two 1/2" Wrenches

1/8” Allen Wrench (if necessary)

Straightedge

Removing the Belt

1. Remove the Bolt, Washer and Locknut from the lower Belt Guard to Frame

mounting (Figure 23).

2. Remove the two Locknuts and Washers from the two Belt Guard to

Sideplate mounting locations.

3. Remove the Belt Guard.

4. Loosen the Engine mounting hardware (Figure 24).

5. Loosen the Adjusting Bolt on the Belt Tensioner enough to slide the Engine

forward until the belt is loose enough to remove.

6. Remove the Belt from the Clutch and Sheave.

Installing and Adjusting the Belt

Note: The Belt Tensioner Adjusting Bolt may need to be loosened up more per the

previous instructions, “Removing the Belt”, to enable you to install a new

Belt.

1. Install the Belt onto the Sheave and Clutch.

2. Tighten the Adjusting Bolt on the Belt Tensioner to take up the slack in the

Belt, but not too tight at this point (Figure 24).

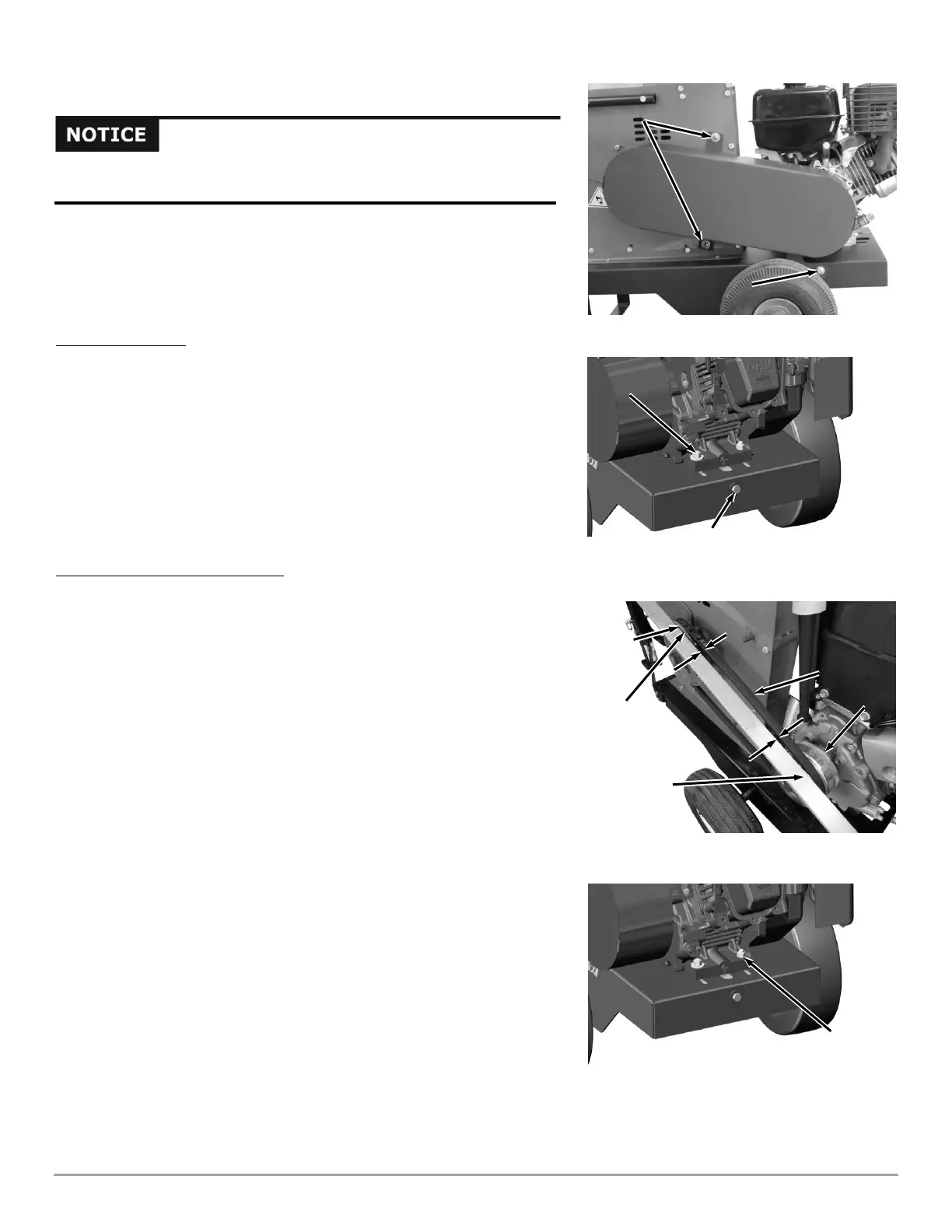

3. Check the alignment of the Clutch with the Sheave by placing a Straightedge

against the Sheave outside face near, but not touching, the Clutch Pulley

(Figure 25).

4. Check the gap from the Straightedge to the Belt near the Sheave and near

the Clutch. If the gap is the same then no adjustment is needed. If the gap

is not the same then adjustment is necessary, correct the alignment as

follows:

a) Loosen the Engine hardware only at three places and leave the last

one tight so the Engine can be rotated to align the Clutch with the

Sheave (Figure 26).

b) Tighten the Engine hardware to hold it in position.

c) Recheck the alignment and perform step a) again as needed..

5. Tighten the Engine Hardware (Figure 24)

Straightedge

On side face

of Sheave

Straightedge

above Clutch

Pulley

Use only DR belts on your machine. The belts have been thoroughly tested

and proven for many hours of use.

Loading...

Loading...