24 DR

®

SELF-FEEDING WOOD CHIPPER

Grease Fittings

Your CHIPPER was greased at the Factory. The operator needs to periodically

lubricate the two Bearings of the Chipper Assembly.

Tools and Supplies needed:

• Two 1/2" Wrenches

• Flexible hose grease gun

• Lithium grease

• Clean cloth

• 1/8” Allen Wrench

• Loctite® 243

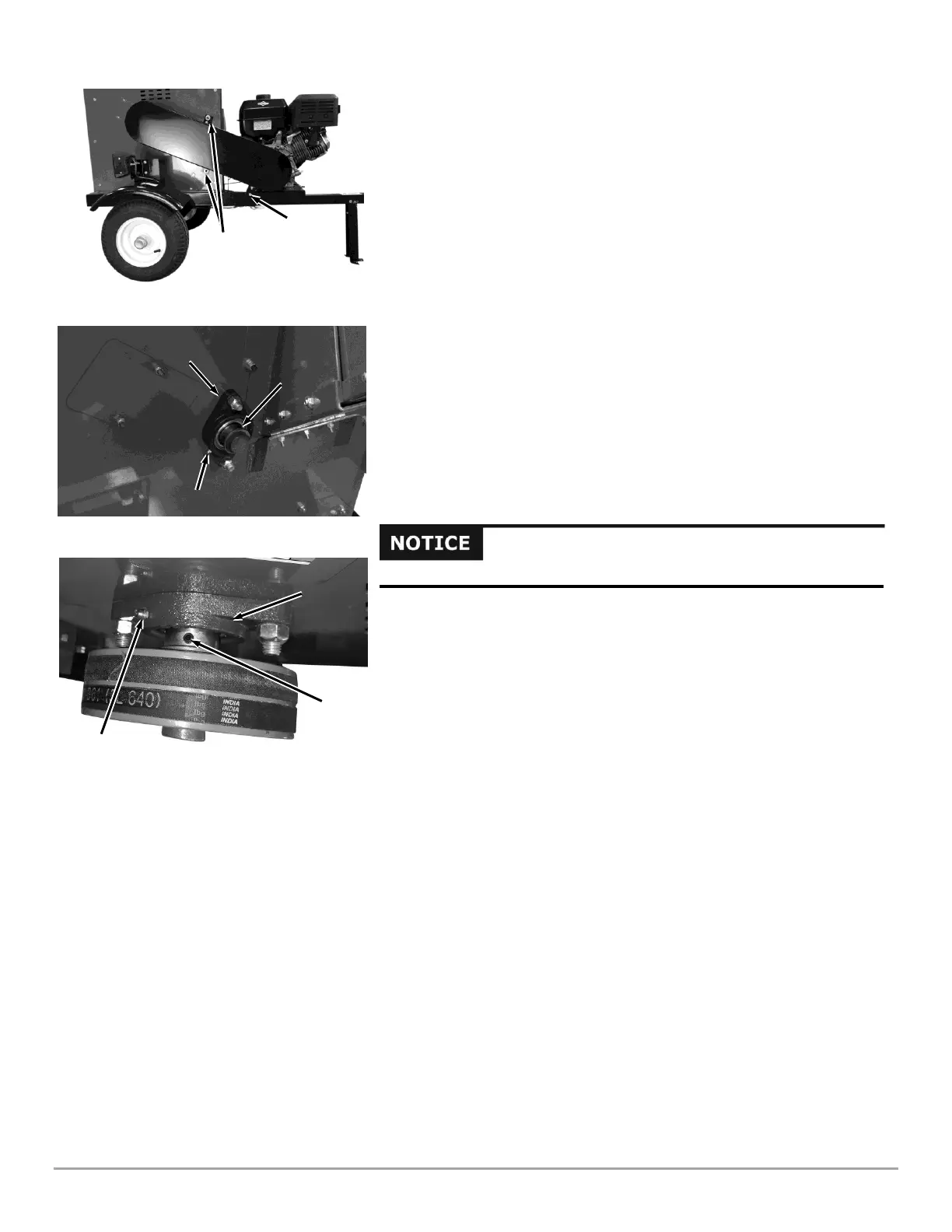

1. Remove the Bolt, Washer and Locknut that attaches the lower area of the

Guard to the Frame (Figure 38).

2. Remove the two Locknuts and Washers at the center of the Guard.

3. Remove the Guard.

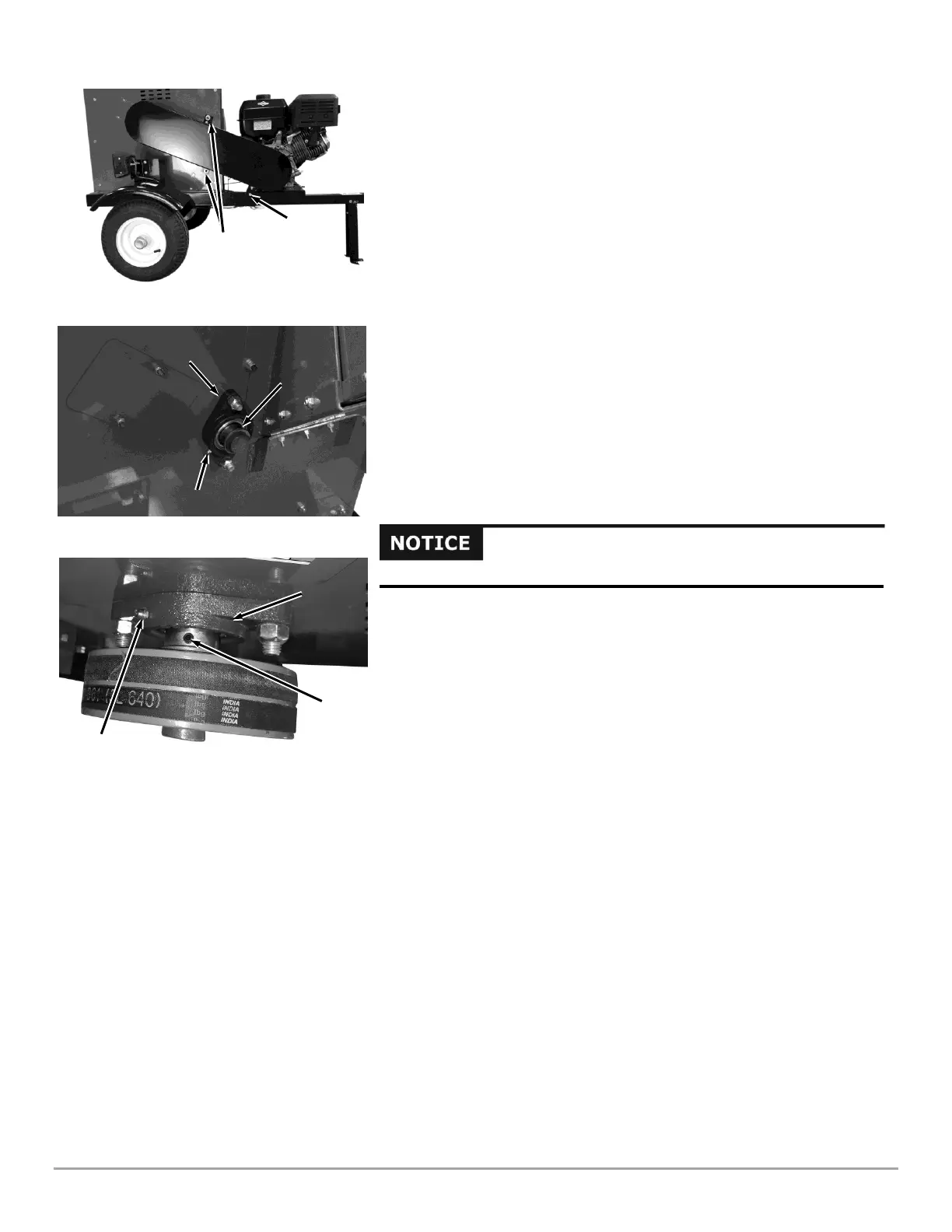

4. Wipe all debris from the grease fitting on the Hopper side (Figure 39) and

the Belt side (Figure 40) with a clean cloth.

5. Apply no more than three pumps of quality general-purpose lithium grease

with a hand-pumped grease gun to each Bearing Grease Fitting.

6. Check the Set Screws for tightness. If they are not tight, remove them,

apply Loctite® to the threads, then reinstall and tighten the Set Screws.

7. Replace the Belt Guard when finished.

Loading...

Loading...