Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:16

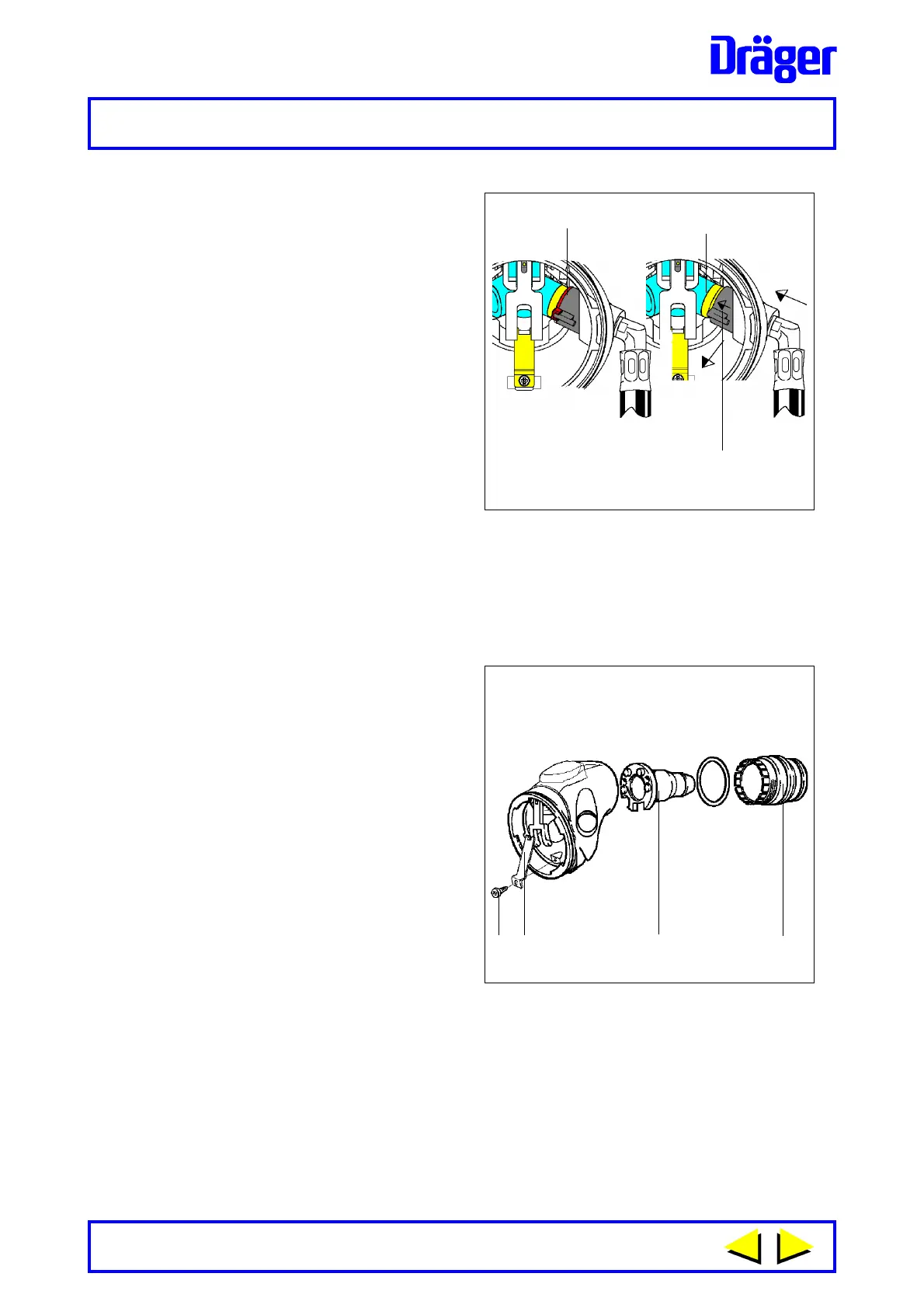

Refer to Figure 15.

Important Note: Spacer (1) must be

removed before attempting to

remove Clip (2).

4 Insert the hook end of the

retractor tool into the hole in the

side lugs of the spacer (1) - pull

and remove spacer. While

keeping the hose fully inserted

into the air transfer block (3),

slide the clip (2) towards the air

transfer block to release clip

from hole in body. Insert the

hook end of the retractor tool

under the extended pin of the

clip (2) then pull to remove the

clip from end fitting of the hose.

Grip and pull the hose to

remove the tailpiece from the

body of the demand valve.

Note:

Scrap spacer (1) and clip (2) –

Do Not

re-use

.

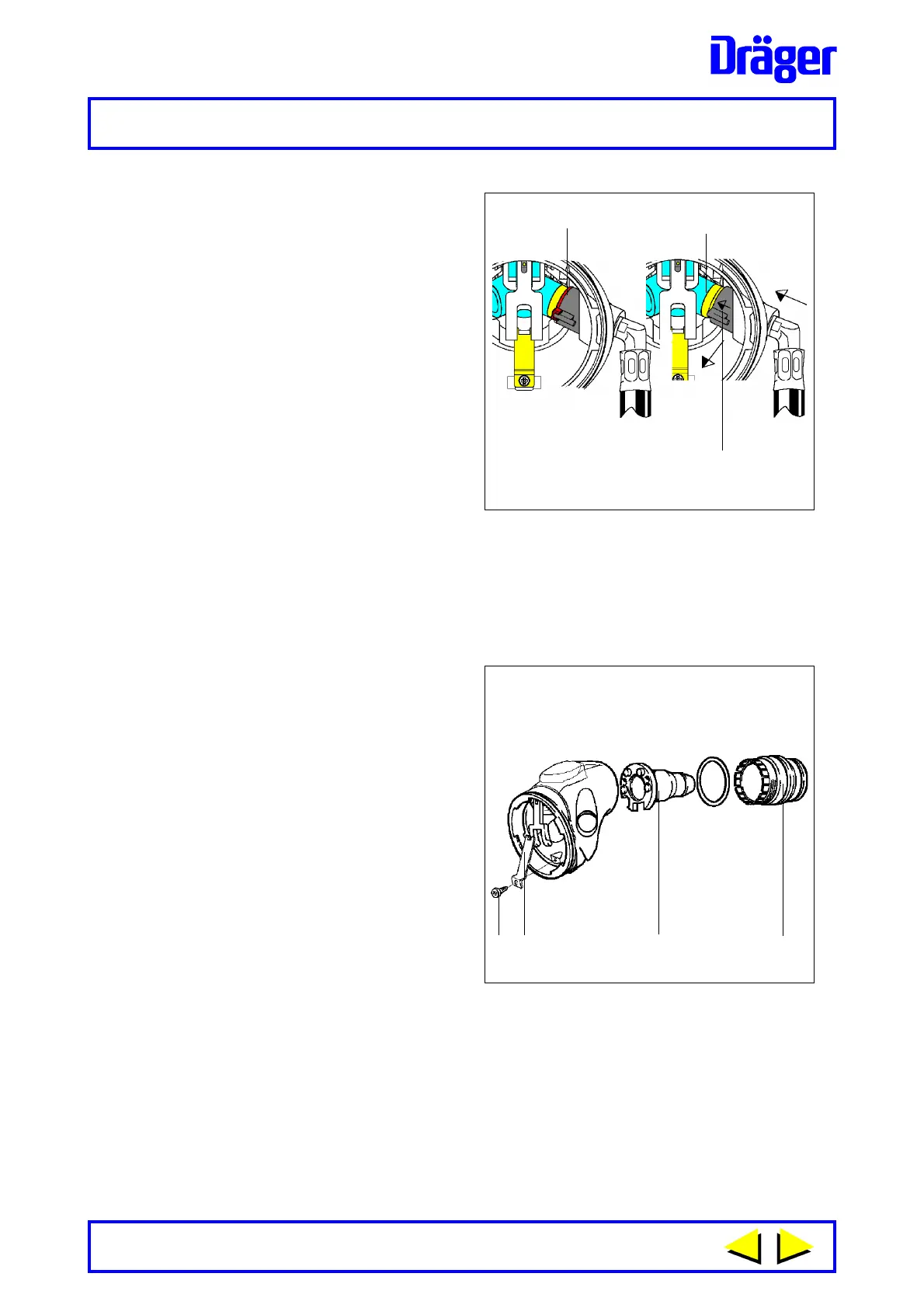

Refer to Fig. 16.

5 Using posi-drive screwdriver

unscrew retaining screw (1) until

the locking arm (2) is able to be

withdrawn from castellation of

connector (3).

6 Remove connector as follows.

Note: Do Not

attempt to remove push-

in or screw-in type connectors

with locking arm located in

castellation of connector.

12 34

Fig. 16

1140

Fig. 15

1134

1

2

3

Push-in Type - A

Unscrew push-in type connector (anti-clockwise) from demand valve

body then remove injector pipe (4).

Screw-in Types - AE and N

Use connector tool (3310679) - insert pins of tool into swivel connector -

rotate to align slots of fixed end of connector and insert pins - unscrew

(anti-clockwise) to remove screw type connector and handwheel

assembly from demand valve body. Remove injector pipe (4).

Loading...

Loading...