Introduction

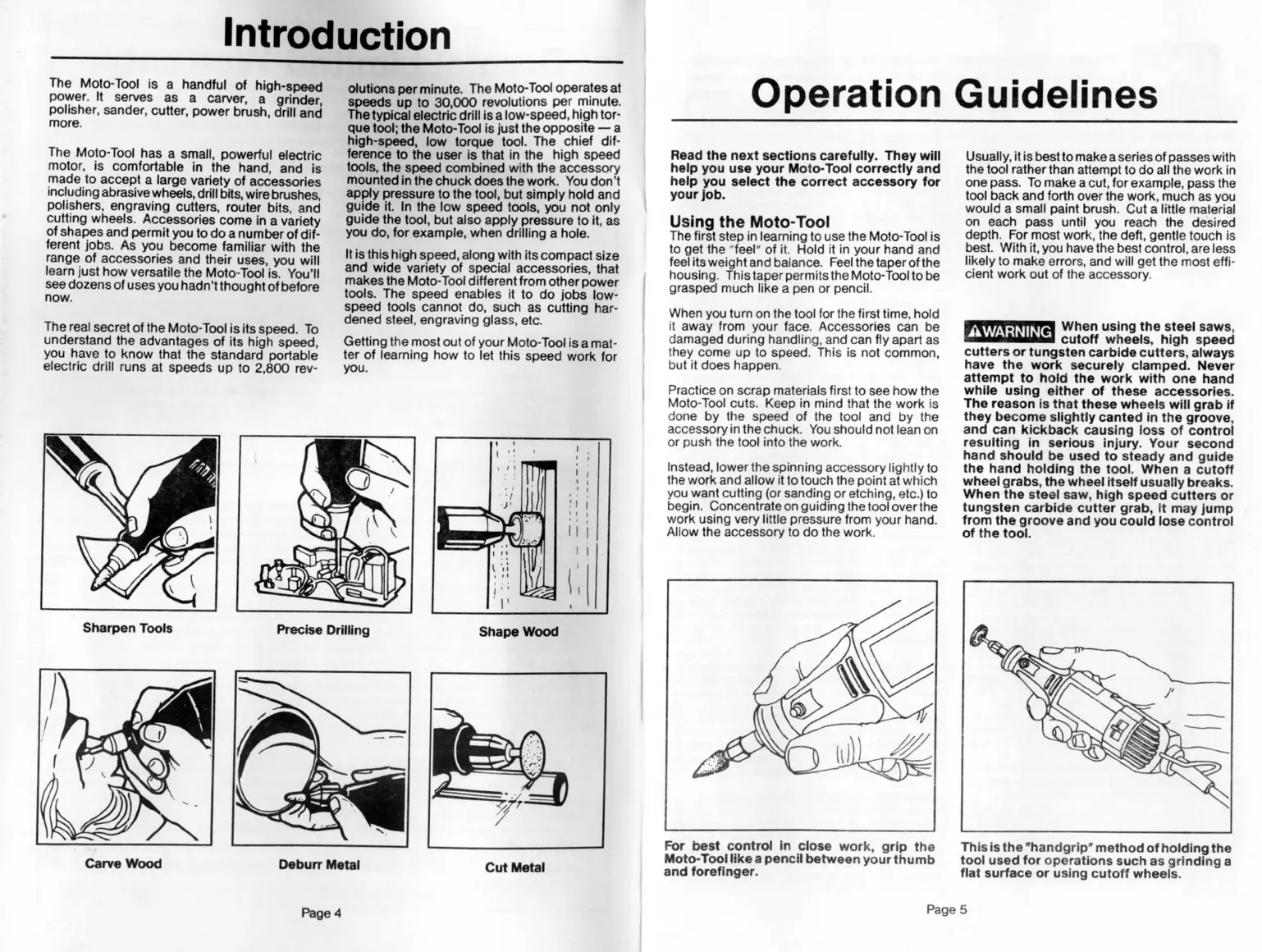

The Moto-Tool is a handful of high-speed

power. It serves as a carver, a grinder,

polisher, sander, cutter, power brush, drill and

more.

The Moto-Tool has a small, powerful electric

motor, is comfortable in the hand, and is

made to accept a large variety of accessories

including abrasive wheels, drillbits, wire brushes,

polishers, engraving cutters, router bits, and

cutting wheels. Accessories come in a variety

of shapes and permit you to do a number of dIf-

ferent jobs. As you become familiar with the

range of accessories and their uses, you will

learn just how versatile the Moto-Tool is. You'll

see dozens of uses you hadn't thought of before

now.

The real secret of the Moto-Tool is its speed. To

understand the advantages of its high speed,

you have to know that the standard portable

electric drill runs at speeds up to 2,800 rev-

oJutlons per minute. The Moto- Tool operates at

speeds up to 30,000 revolutions per minute.

The typical electric drill is a low-speed, high tor-

que tool; the Moto- Tool Is just the opposite - a

high-speed, low torque tool. The chief dif-

ference to the user Is that in the high speed

tools, the speed combined with the accessory

mounted In the chuck does the work. You don't

apply pressure to the tool, but simply hold and

guide it. In the low speed tools, you not only

guide the tool, but also apply pressure to it, as

you do, for example, when drilling a hole.

It is this high speed, along with its compact size

and wide variety of special accessories, that

makes the Moto- Tooldifferent from other power

tools. The speed enables it to do jobs low-

speed tools cannot do, such as cutting har-

dened steel, engraving glass, etc.

Getting the most out of your Moto- Tool Is a mat-

ter of learning how to let this speed work for

you.

Sharpen Tools

Precise Drilling

. I

I .

~

"

I I

I I

I I

I

I

:,

I

II I

'.

I

II I

I I

,.,

'I'

(,(

I

Shape Wood

Carve Wood

Deburr Metal

Page 4

Cut Metal

Operation Guidelines

Read the next sections carefully. They will

help you use your Moto-Tool correctly and

help you select the correct accessory for

your job.

Using the Moto- Tool

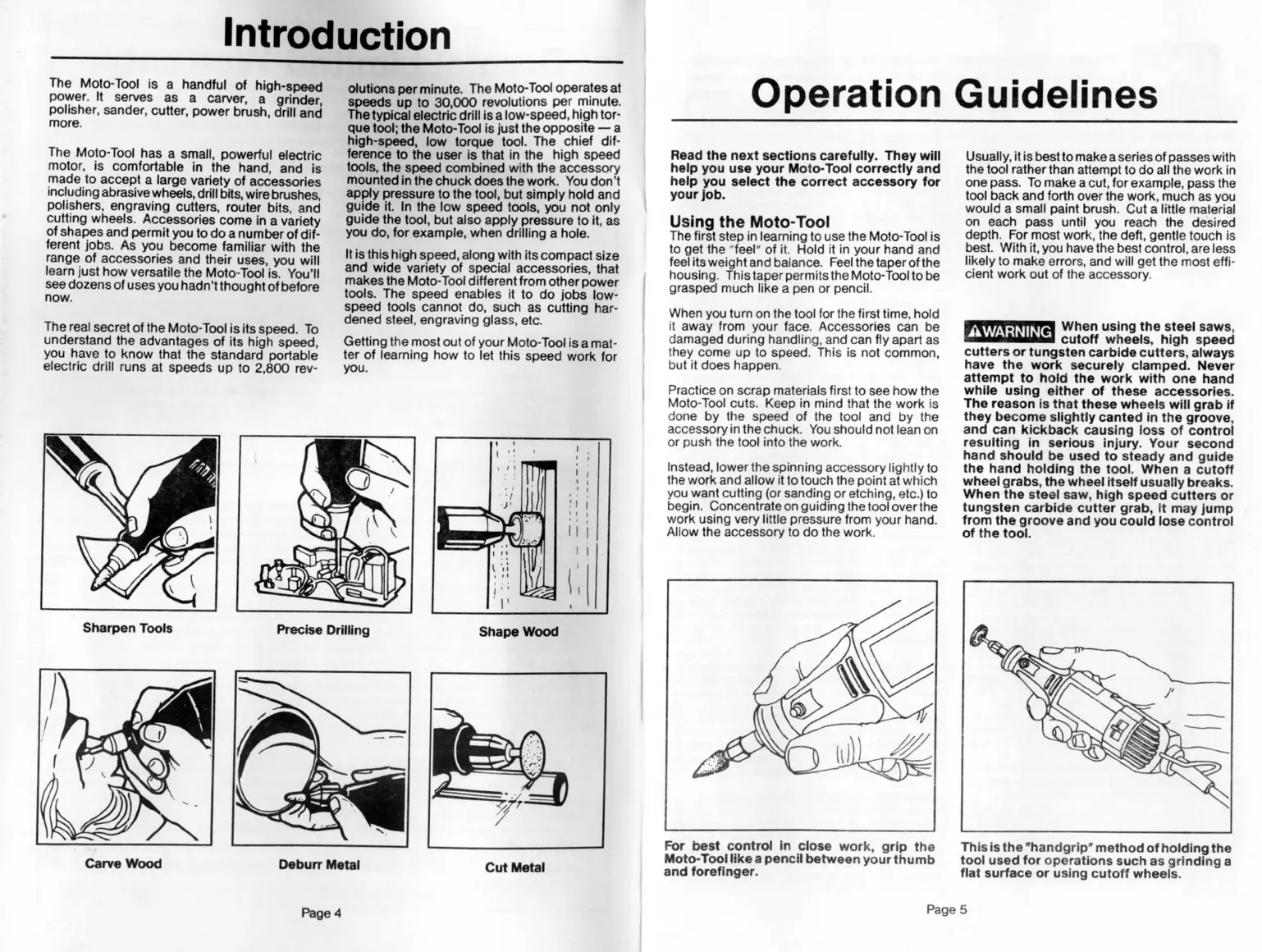

The first step in learning to use the Moto- Tool is

to get the "feel" of it. Hold it in your hand and

feel its weight and balance. Feel the taper of the

housing. This taper permits the Moto- Tool to be

grasped much like a pen or pencil.

When you turn on the tool for the first time, hold

it away from your face. Accessories can be

damaged during handling, and can fly apart as

they come up to speed. This is not common,

but it does happen.

Practice on scrap materials first to see how the

Moto. Tool cuts. Keep in mind that the work is

done by the speed of the tool and by the

accessory in the chuck. You should not lean on

or push the tool into the work.

Instead, lower the spinning accessory lightly to

the work and allow it to touch the point at which

you want cutting (or sanding or etching, etc.) to

begin. Concentrate on guiding the tool over the

work using very little pressure from your hand.

Allow the accessory to do the work.

For best control In close work, grip the

Mota-Tool like a pencil between your thumb

and forefinger.

Usually, it is best to make a series of passes with

the tool rather than attempt to do all the work in

one pass. To make a cut, for example, pass the

tool back and forth over the work, much as you

would a small paint brush. Cut a little material

on each pass until you reach the desired

depth. For most work, the deft, gentle touch is

best. With it, you have the best control, are less

likely to make errors, and will get the most effi-

cient work out of the accessory.

~ When using the steel saws,

~ cutoff wheels, high speed

cutters or tungsten carbide cutters, always

have the work securely clamped. Never

attempt to hold the work with one hand

while using either of these accessories.

The reason Is that these wheels will grab If

they become slightly canted In the groove,

and can kickback causing loss of control

resulting In serious Injury. Your second

hand should be used to steady and guide

the hand holding the tool. When a cutoff

wheel grabs, the wheel Itself usually breaks.

When the steel saw, high speed cutters or

tungsten carbide cutter grab, It may jump

from the groove and you could lose control

of the tool.

This Is the "handgrlp" method of holding the

tool used for operations such as grinding a

flat surface or using cutoff wheels.

Page 5

Loading...

Loading...