;;

The_d"'YPo..""",,,,,,,,,,,in_" -

,

s being thrown into

~

the eyes, which can resuh in severe eye damage. Always wear safety glasses

Z

I'

..

or eye shields before commencing power tool operation. We recommend

,

I' WIde VIsIon Safety Mask for use over,spectacles or standard safety glasses.

Whenever you hold the tool, be careful not

to cover the air vents with your hand. This

blocks the air flow and causes the motor

to overheat.

'

ALWAYS UNPLUG MOTO-TOOL BEFORE

CHANGING ACCESSORIES, CHANGING

COLLETS OR SERVICING YOUR MOTO TOOL

l.-=-.J

~

~

~

TO LOOSEN COLLET

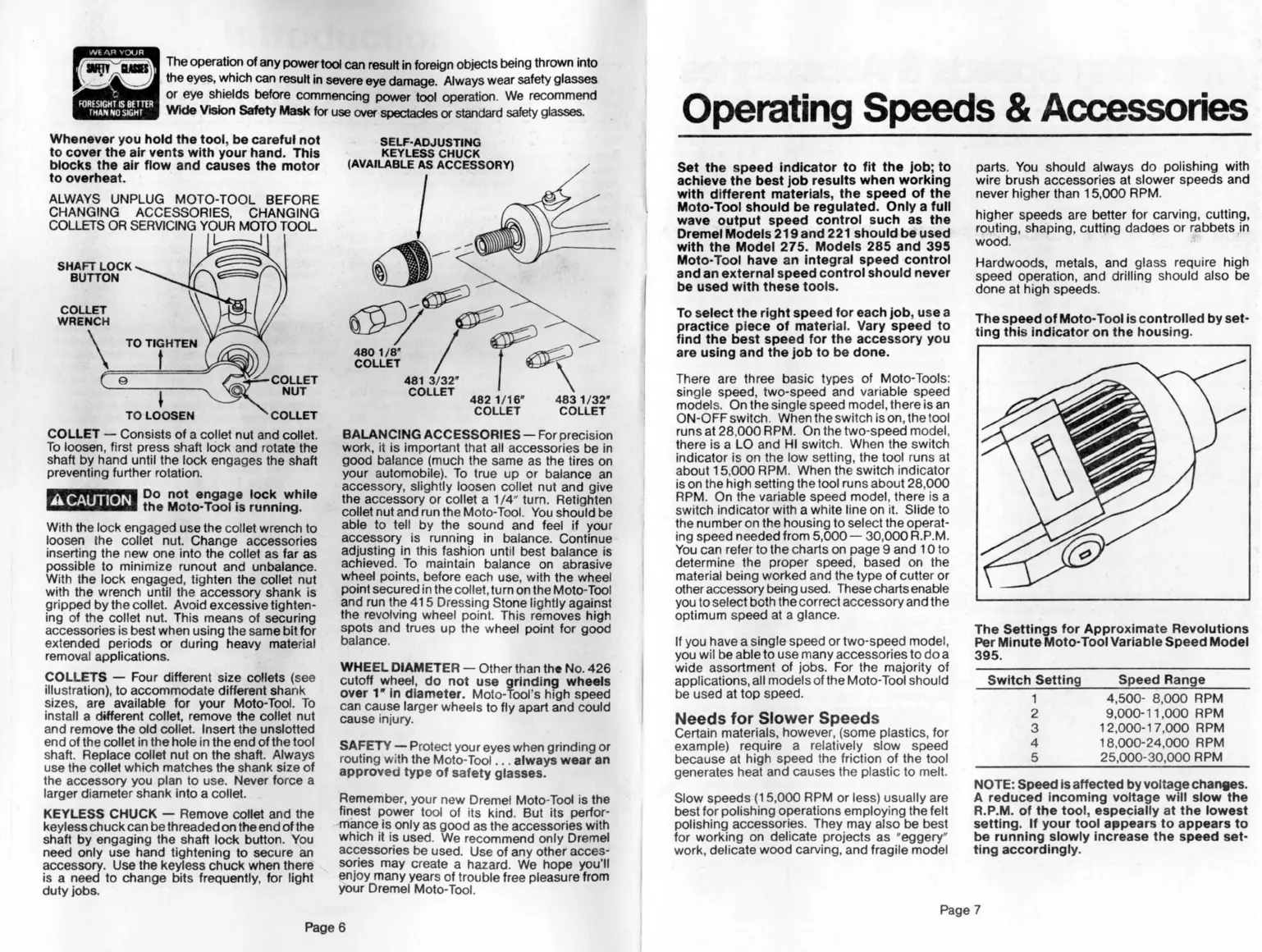

COLLET - Consists of a collet nut and collet.

To loosen, first press shaft Irick and rotate the

shaft by hand until the lock engages the shaft

preventing further rotation.

~

Do not engage lock while

~ the Moto-Toolls running.

With the lock engaged use the collet wrench to

loosen the collet nut. Change accessories

inserting the new one into the collet as far as

possible to minimize runout and unbalance.

With the lock engaged, tighten the collet nut

with the wrench until the accessory shank is

gripped by the collet. Avoid excessive tighten-

ing of the collet nut. This means of securing

accessories is best when using the same bit for

extended periods or during heavy material

removal applications.

COLLETS - Four different size collets (see

illustration), to accommodate different shank

sizes, are available for your Moto-Tool. To

install a different collet, remove the collet nut

and remove the old collet. Insert the unslotted

end ofthe collet in the hole in the end of the tool

shaft. Replace collet nut on the shaft. Always

use the collet which matches the shank size of

the accessory you plan to use. Never force a

larger diameter shank into a collet.

KEYLESS CHUCK - Remove collet and the

keyless chuck can be threaded on the end ofthe

shaft by engaging the shaft lock button. You

need only use hand tightening to secure an

accessory. Use the keyless chuck when there

is a need to change bits frequently, for light

duty jobs.

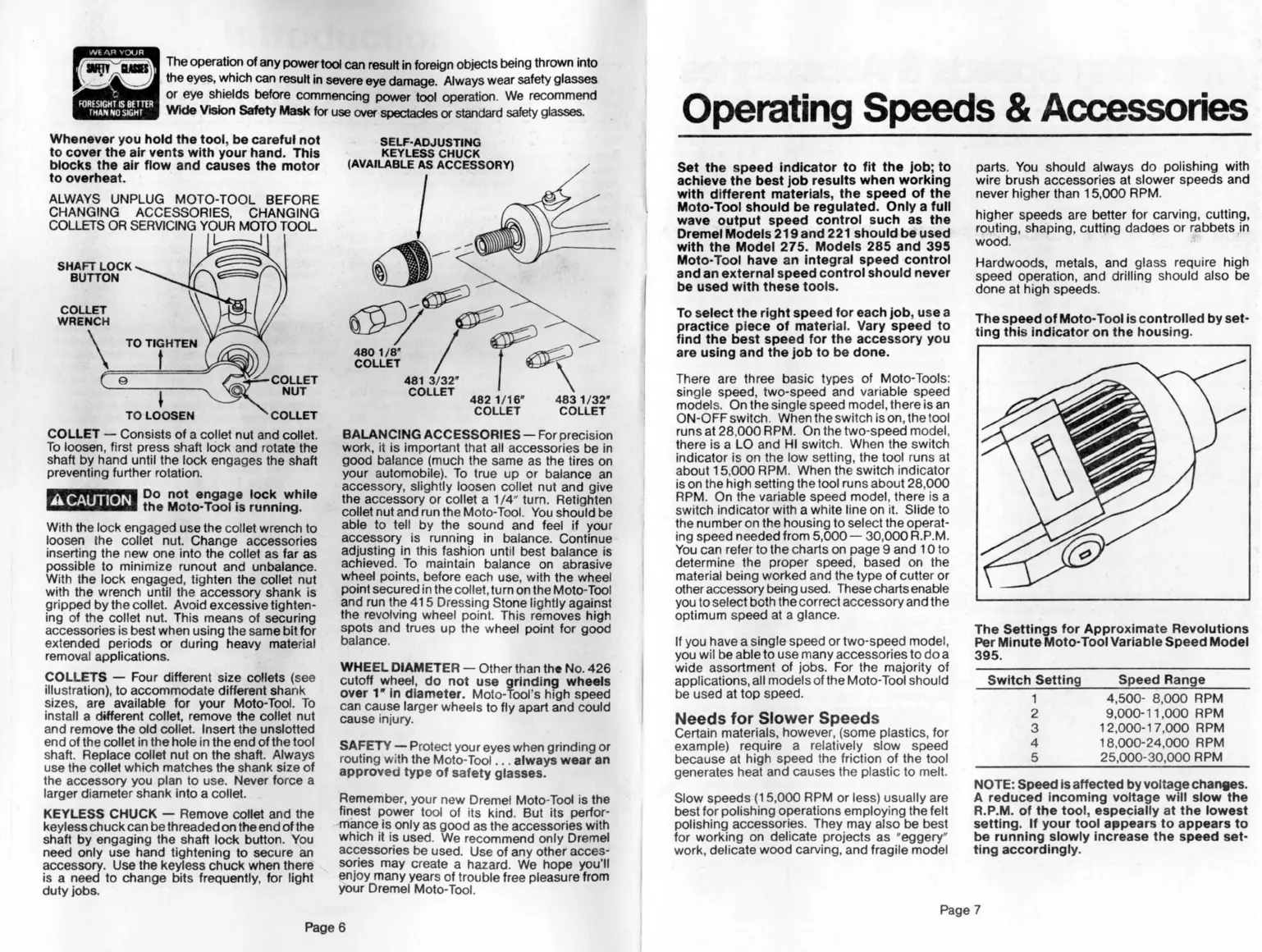

SELF.ADJUSTING

KEYlESS CHUCK

(AVAILABLE AS ACCESSORY)

I

0\)-

~-

@~~

COLLET

4821/16" 4831132"

COLLET COLLET

BALANCING ACCESSORIES - For precision

work, it is important that all accessories be in

good balance (much the same as the tires on

your automobile). To true up or balance an

accessory, slightly loosen collet nut and give

the accessory or collet a 1/4" turn. Retighten

collet nut and run the Moto- Tool. You should be

able to tell by the sound and feel if your

accessory is running in balance. Continue

adjusting in this fashion until best balance is

achieved. To maintain balance on abrasive

wheel points, before each use, with the wheel

point secured in the collet, turn on the Moto- Tool

and run the 415 Dressing Stone lightly against

the revolving wheel point. This removes high

spots and trues up the wheel point for good

balance.

WHEEL DIAMETER - Other than the No. 426

cutoff wheel, do not use grinding wheels

over 1"ln diameter. Moto-TooI's high speed

can cause larger wheels to fly apart and could

cause injury.

SAFETY - Protect your eyes when grinding or

routing with the Moto-Tool... always wear an

approved type of safety glasses.

Remember, your new Dremel Moto- Tools the

finest power tool of its kind. But its pertor-

--mance is only as good as the accessories with

which it is used. We recommend only Dremel

accessories be used. Use of any other acces-

so~es may create a hazard. We hope you'll

Il'"Joy

many years of trouble free pleasure from

your Dremel Moto-Tool.

Page

6

Operating

Speeds &Accessories

Set the speed Indicator to fit the Job; to

achieve the best Job results when working

with different materials, the speed of the

Moto. Tool should be regulated. Only a full

wave output speed control such as the

Dremel Models 219 and 221 should be used

with the Model 275. Models 285 and 395

Moto. Tool have an Integral speed control

and an external speed control should never

be used with these tools.

Toselect the right speed for each job, use a

practice piece of material. Vary speed to

find the best speed for the accessory you

are using and the job to be done.

There are three basic types of Moto- Tools:

single speed, two-speed and variable speed

models. On the single speed model, there is an

ON-OFF switch. When the switch is on, the tool

runs at 28,000 RPM. On the two-speed model,

there Is a LO and HI switch. When the switch

indicator is on the low setting, the tool runs at

about 15,000 RPM. When the switch indicator

is on the high setting the tool runs about 28,000

RPM. On the variable speed model, there is a

switch indicator with a white line on it. Slide to

the number on the housing to select the operat-

ing speed needed from 5,000 - 30,000 R.P.M.

You can refer to the charts on page 9 and 10 to

determine the proper speed, based on the

material being worked and the type of cutter or

other accessory being used. These charts enable

you to select both the correct accessory and the

optimum speed at a glance.

If you have a single speed or two-speed model,

you wil be able to use many accessories to do a

wide assortment of jobs. For the majority of

applications, all models of the Moto- Tool should

be used at top speed.

Needs for Slower Speeds

Certain materials, however, (some plastics, for

example) require a relatively slow speed

because at high speed the friction of the tool

generates heat and causes the plastic to melt.

Slow speeds (15,000 RPM or less) usually are

best for polishing operations employing the felt

polishing accessories. They may also be best

for working on delicate projects as "eggery"

work, delicate wood carving, and fragile model

parts. You should always do polishing with

wire brush accessories at slower speeds and

never higher than 15,000 RPM.

higher speeds are better for carving, cutting,

rOl,lting, shaping, cutting dadoes or rabbets.in

wood. ..'

Hardwoods, metals, and glass require high

speed operation, and drilling should also be

done at high speeds.

The speed of Moto- Tool Is controlled by set.

ting this Indicator on the housing.

The Settings for Approximate Revolutions

Per Minute Moto- Tool Variable Speed Model

395.

Switch Setting

1

2

3

4

5

Speed Range

4,500- 8,000 RPM

9.000-11,000 RPM

12.000-17,000 RPM

18,000-24,000 RPM

25,000-30,000 RPM

NOTE: Speed Isaffected by voltage chantl8s.

A reduced Incoming voltage will slow the

R.P.M. of the tool, especially at the lowest

setting. If your tool al'pears to appears to

be running slowly Increase the speed set.

tlng accordingly.

Page 7

Loading...

Loading...