5

6.2 AUTOMATIC VERSION

The Automatic version of the pump is equipped with a built in electronic

controller that controls the pump and monitors feedback from the pressure

and level switches.

The control system settings and human interface is via the 16x2 character LCD

display on the front face and the 5 programming buttons. A Reset button is

located on the lower left side.

The Manual cycle button present on the Manual version remains but on the

Automatic version will cause the local built in control system to run a

lubrication cycle.

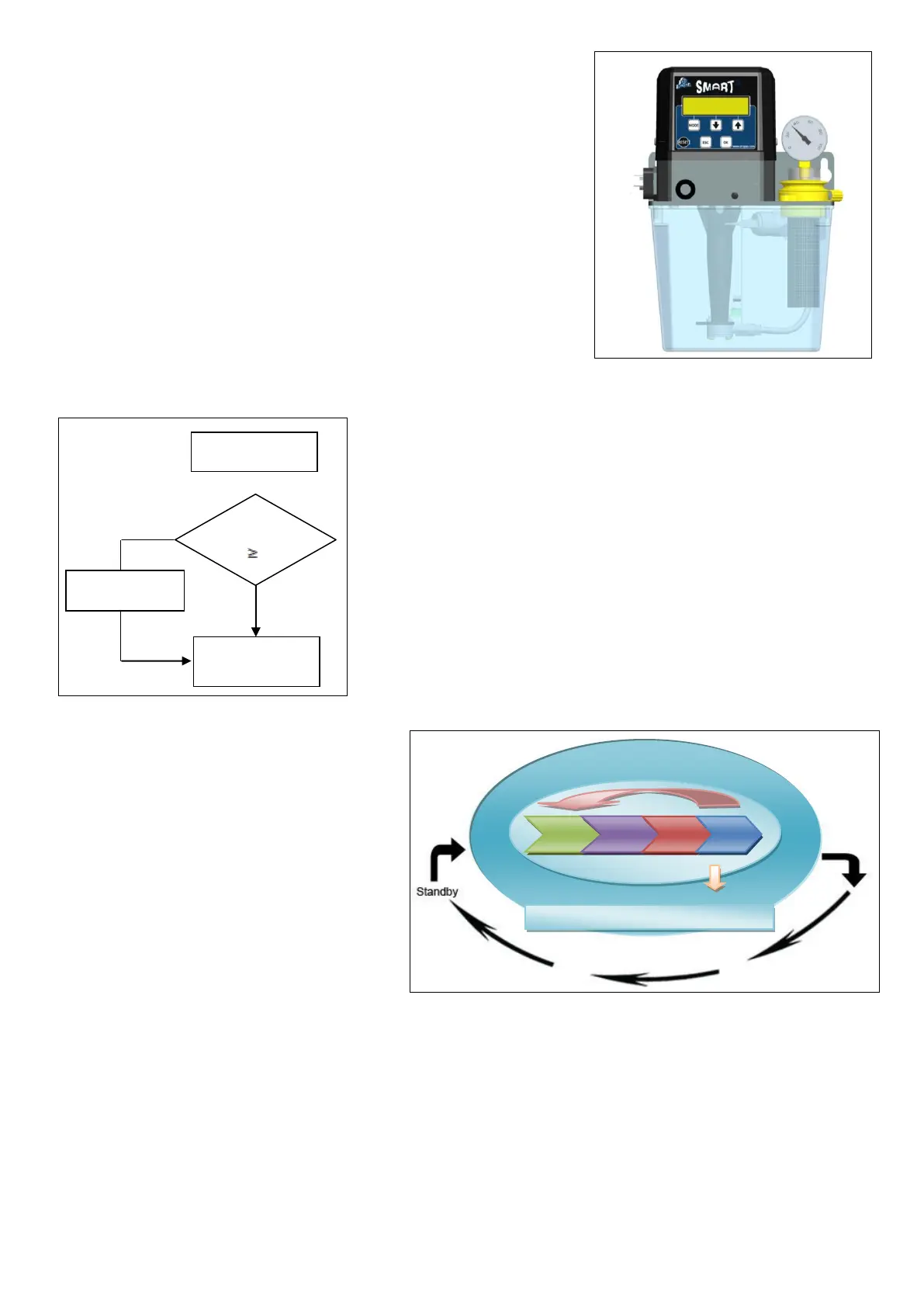

SMART3 automatic pumps can be programmed to operate withintermittent

lubricationcycle that involves the following three phases:

A) Prelube -> pre- lubrication when system is powered on

B) Lube (lube – wait) ->the lubrication cycle

C) Standby

A)PRELUBE

The pre-lube phaseallows the user to run a set number of lubrication cycles

(250 Max) when the pump is powered on. This typically is used when a

system needs additional quantities of oil on power up.

Prelube takes place:

- on POWER-ON;

- on RESET;

- Any time new parameters are set.

When prelube is set to “0”, the prelube phase is completed skipped and the

pump will work just with the normal lube and standby phases.

B) LUBE

This step is made up of a set of cycles (max 999

cycles) during which lubrication is carried out.

Each cycle consists of two sub-cycles (lube and

wait) and involves the monitoring of timers

and/or inputs:

- Duringlube, system delivers lubricant to the

lubrication points;

- Duringwait, a timer defines the wait time

between two or more lube cycles or before the

beginning of the standby phase (in case only 1

lube cycle was set).

There are two types of lube:

TIMER: The pump will simply run for the On time

and then enter standby mode;

PS: The pump will run until the pressure switch is made and pressure is maintained for a check period. Subsequently, the

pump will be switched off and the standby phase will commence.

C) STANDBY

During this step lubrication system is idle until the next lubrication cycle. There are three ways to regulate standby:

TIMER: a timer regulate system idling;

PULSE: a pulse counter regulate system idling;

BOTH: both a timer and a pulse counter regulate system idling. The type of standby will depend on which of these two

events will start first.

For conditions of use and programming cycles see chapter 8.

Lubrication Cycle can be repeated up to

250 times.

Lubrication Phase can comprise of many Lubrication Cycles

Loading...

Loading...