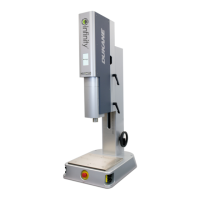

Why are parts marking when using Dukane iQ?

- PPeter HunterDec 1, 2025

Parts marking during welding with a Dukane system can occur due to several reasons. It may be caused by insufficient force during welding. Increase trigger force and weld speed. If using Match Detect, decrease the value of the parameter After Force Decreases By. If the horn heats up, check for a loose stud and tighten if necessary, or loosen and retighten the horn tip. Ensure the horn and booster are coupling well, and visually check the horn for cracks. Reduce the weld duration. High spots in the part, use of raised lettering, or improper fit of the part to the fixture can also cause marking. Check the part dimensions, the fit of the horn to the part, and the fixture for proper support. If oxide from the horn is being transferred, place polyethylene film between the horn and the part or u...