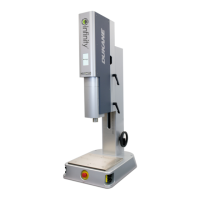

What causes diaphragm damage in Dukane iQ Welding System?

- DDr. Jennifer Daniels DDSSep 1, 2025

Diaphragm damage in a Dukane Welding System can be caused by excessive horn amplitude. Reduce the horn amplitude or dampen the welding area to absorb the excessive vibrations. Excessive exposure to ultrasound can also be a factor; reduce the weld duration and increase the horn amplitude and/or weld speed. Improper gate location/design/thin-wall sections can contribute; check gate placement, change the shape of the gate, add stiffening ribs to the part, and increase the thickness of the material on the underside of the gate area. If using a 15 kHz system, consider using a 20 kHz system. Lastly, the type of horn and/or its placement can cause damage; check for the proper horn/part fit and change the horn if necessary.