30

Maintenance Schedule

(

Refer also to Summary Chart, above)

1 Bolted Connections

All bolted connections of the machine should be

checked after the first 3 to 5 hours of operation and

retightened if necessary and thereafter at regular

intervals. It is suggested that this is done every 500

hectares or annually, whichever occurs first.

2 Drive Chains

All drive chains should first be checked after every 20

hours of operation and thereafter weekly or after 75Ha

of operation as follows:-

The metering units of the seed drill are driven via

driveshafts and roller chains from the drive wheel.

Cleaning of the roller chains is recommended after

long periods of operation. Remove the chain, wash in

kerosene and then dip them in heated grease or oil

or spray them with a suitable commercial roller chain

lubricant. Do not heat the black plastic chain tensioners;

just wash in kerosene and refit. The lubricant on the

chain will transfer to the tensioner in use.

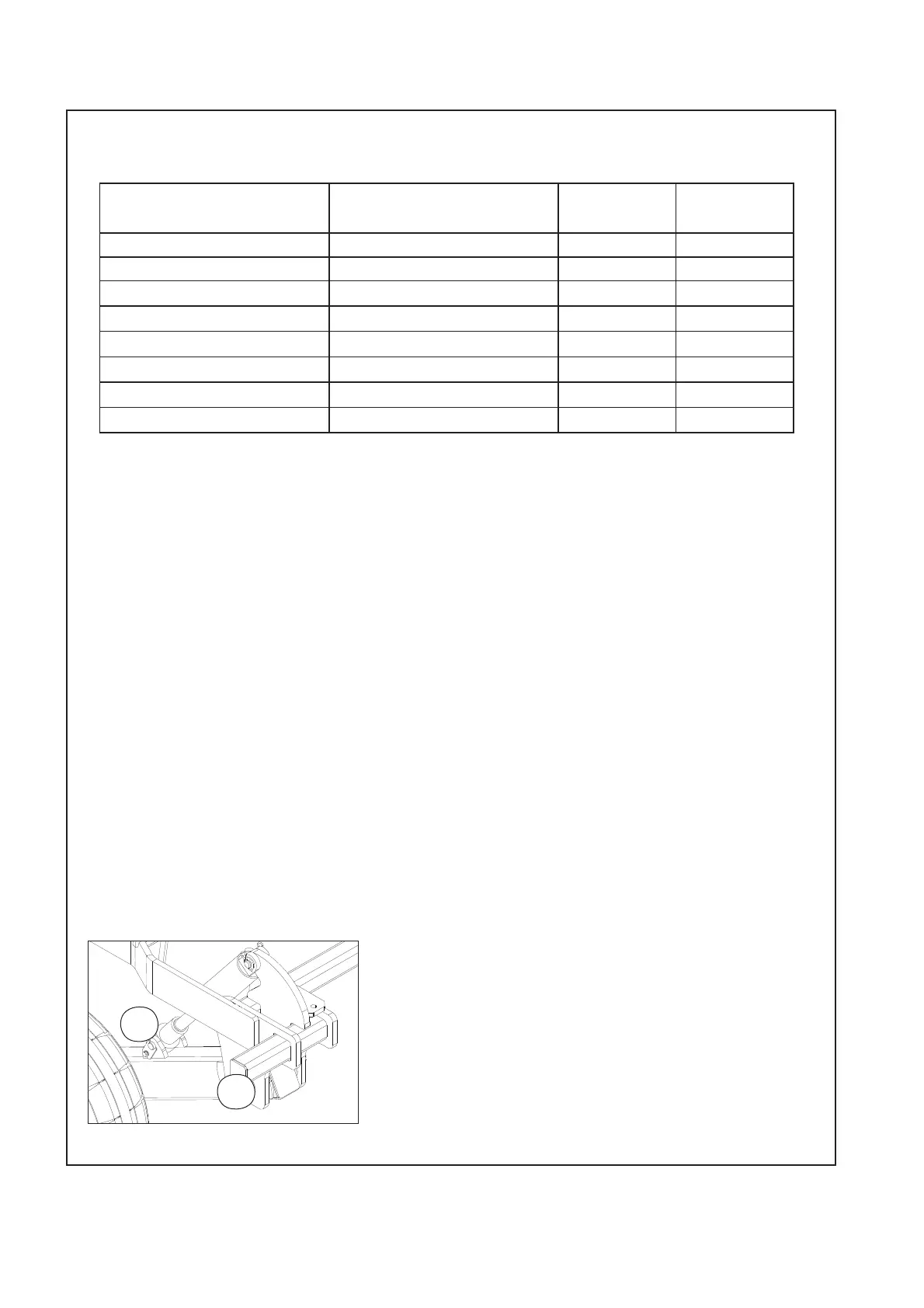

4 Wheel Arm Pivots

Wheel arm pivots must be greased regularly (weekly or

after every 75Ha) to provide lubrication and flush out

any dirt. (1).

5. Depth Adjustment Collar

Grease the depth adjustment collar (2) regularly to

ensure it does not seize up. Also check for dirt buildup

around the ram shaft seals to ensure seal damage does

not occur. Refer Fig 26

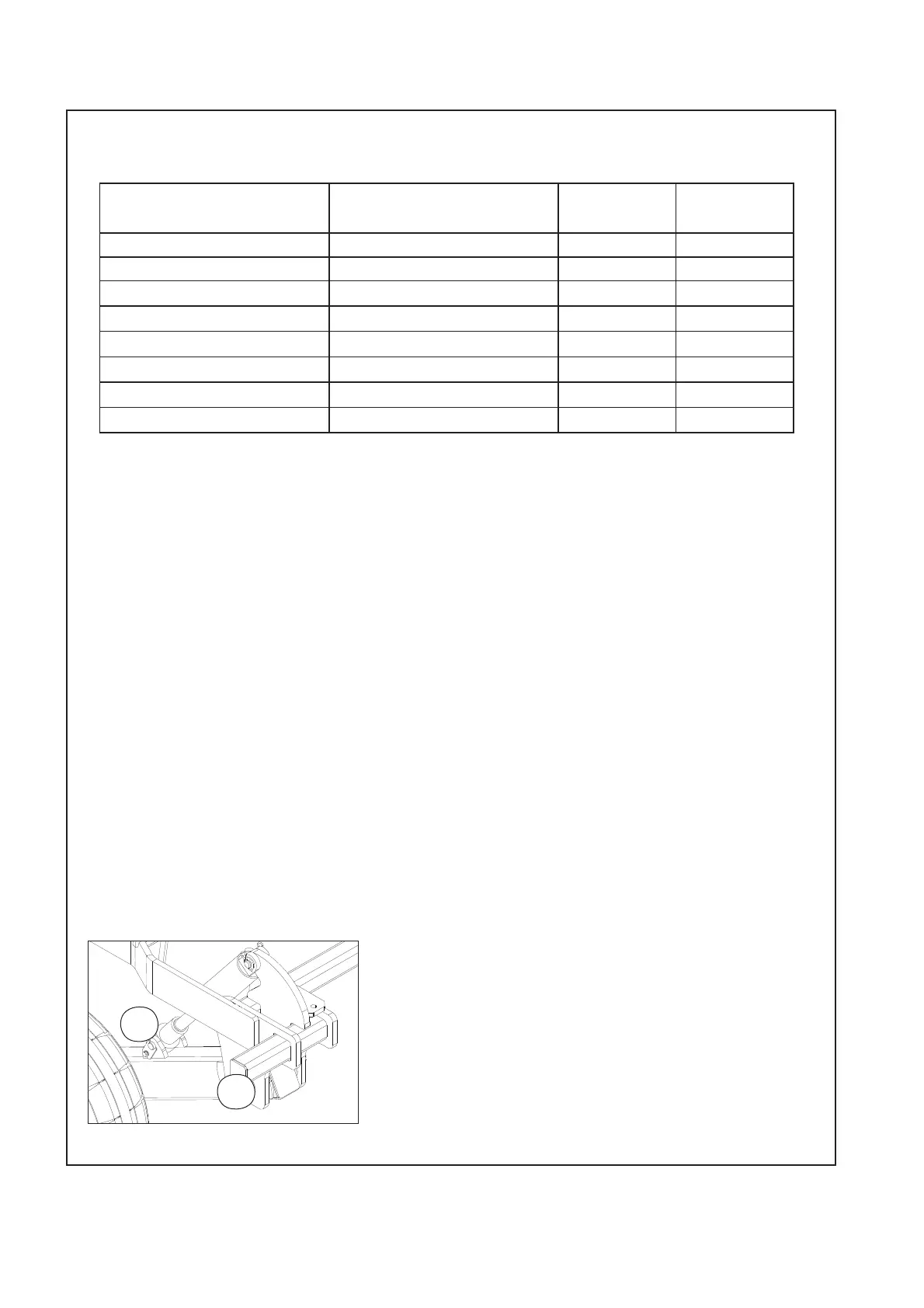

Maintenance & Care - Lubrication Instructions

Components

Daily Weekly Pre Season

(or after 20Ha) (or after 75Ha) (or 500 Ha)

Depth Adjustment Collar ●●●

Wheel Nuts ●●●

Pivot Pin Fasteners ●●

Coupling & Safety Chains ●●

Roller Chains ●●

Hydraulics (Oil Leaks) ●●

Tyre Pressures (58psi /4.0 bar) ●●

Bolted Connections ●

‘Enviro DD35’ Maintenance & Care

1

2

Loading...

Loading...