11

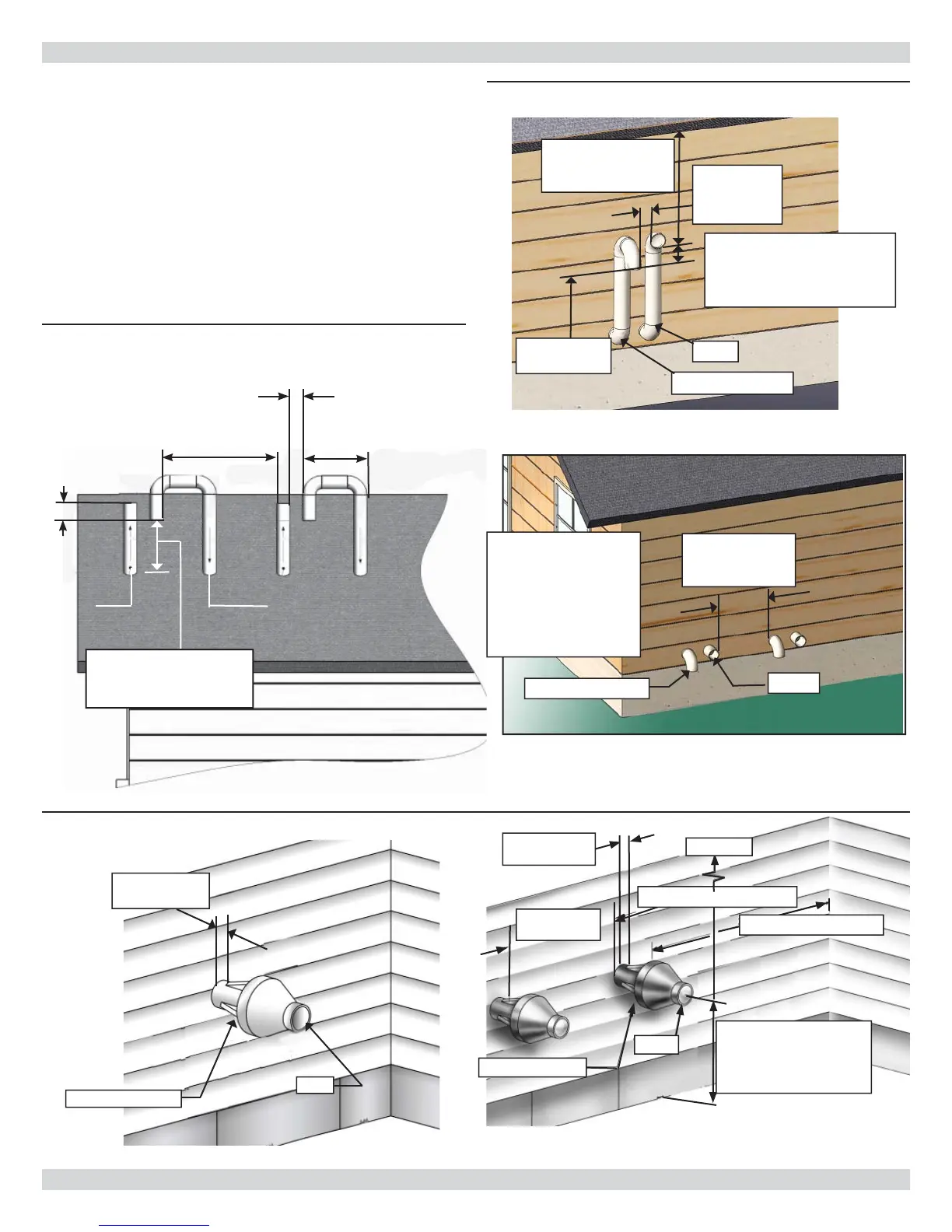

If concentric vent termination is being used, refer to

Figure 10

for proper setup.

5 - COMBUSTION AIR/ VENT REQUIREMENTS

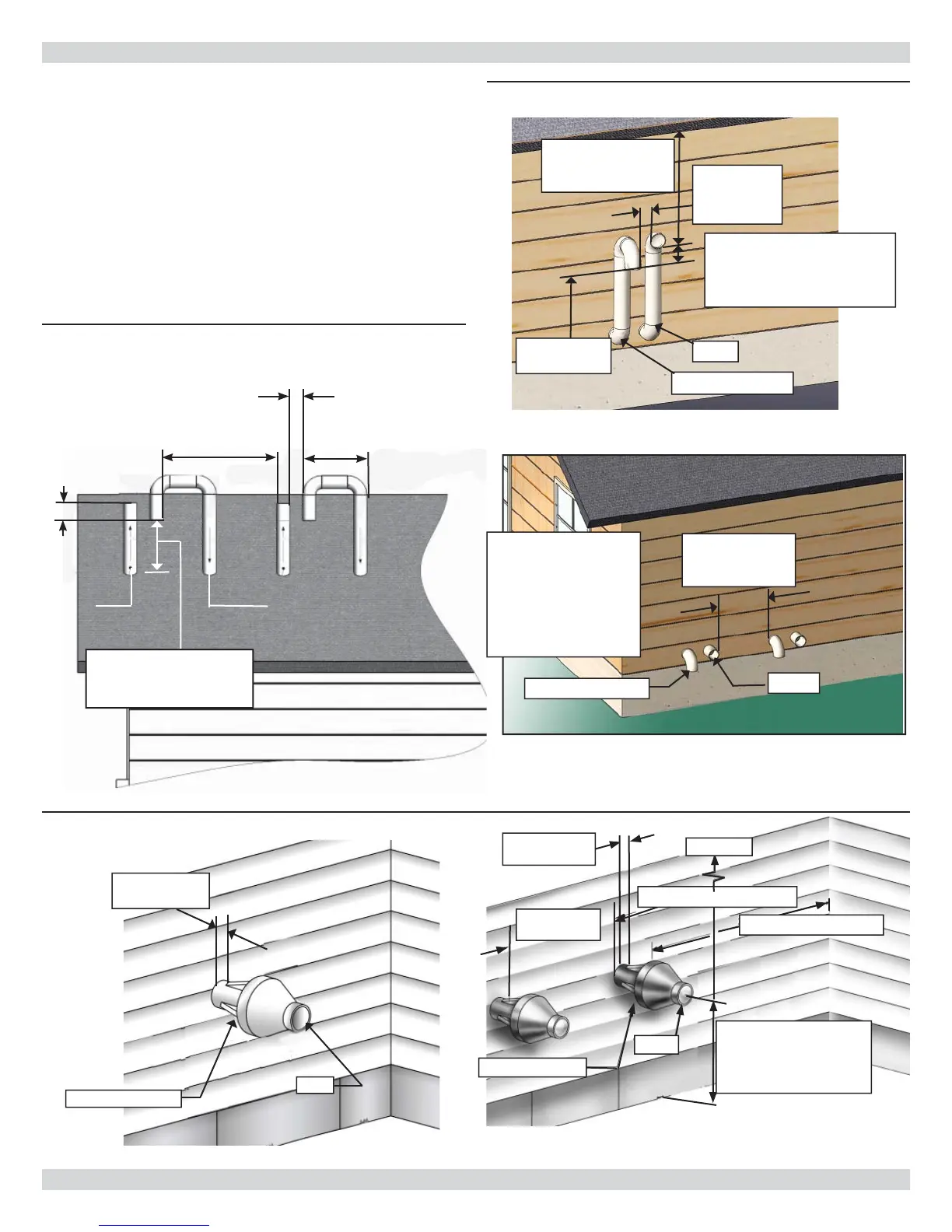

Figure 8 - Roof Vent / Intake Terminations

Figure 9 - Sidewall Vent/Intake Terminations

Combustion Air/Vent Pipe Requirements

Boiler requires dedicated direct vent system. Direct vent

system, all air for combustion is taken directly from outside

atmosphere, and all fl ue products are discharged to outside

atmosphere.

Combustion air and vent pipe connections must terminate

together in same atmospheric pressure zone, either

through roof or sidewall (roof termination preferred). See

Figures 8 and 9

for required clearances.

12" (305mm)

Minimum

8" (203mm)

Minimum

15" (381mm)

Maximum

3" (76mm)

Maximum

Vent Combustion

Air

12" (305mm)

Minimum Above

Anticipated Snow Line

Vent

3" (76mm)

Minimum

Separation

12" (305mm)

Minimum From

Overhan

g

12" (305mm) Separation

Between Bottom Of

Combustion Air Intake

And Bottom Of Vent

See Snow &

Ice Page 23

Combustion Air

Vent

12" (305mm)

Minimum

Separation

Combustion Air

Figure 10 - Concentric Vent Terminations

Combustion Air

Vent

1" (26mm)

Maximum

Maintain 12"

clearance above

highest anticipated

snow level or grade

* See Note

Below

36"(0.9m) Minimum

Maintain 12"(305mm)

Clearance Above Highest

Anticipated Snow Level

Or Grade

12" (305mm) Minimum

*Must be less than 4" or greater than 24" Horizontal distance

between end bells of each air intake to prevent fl ue gas recirculation.

1" (26mm)

Maximum

Overhang

• Avoid locations where

snow may drift and block

vent and combustion air.

• Ice or snow may cause

boiler to shut down if

vent or combustion air

becomes obstructed.

Vent

Combustion Air

Loading...

Loading...