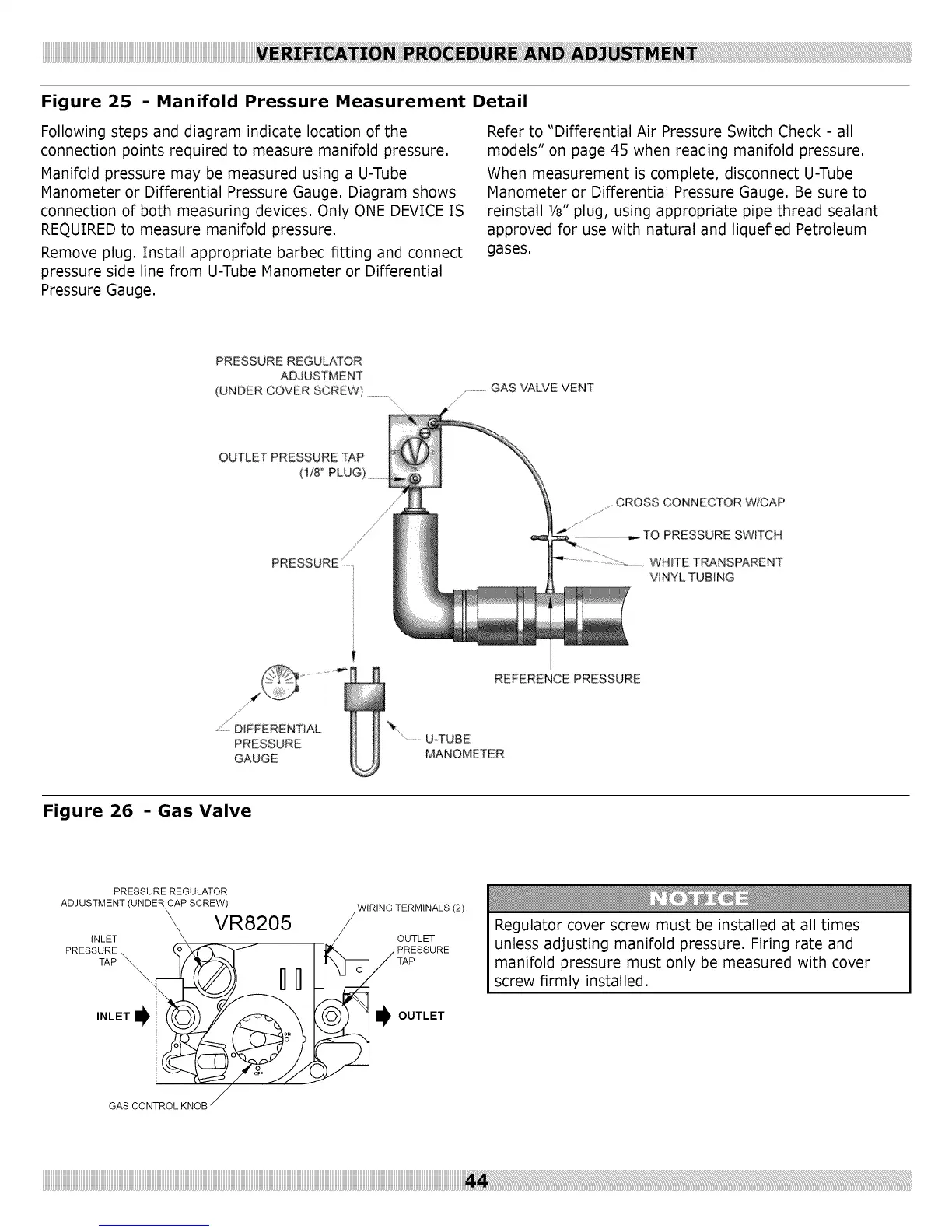

Figure 25 - Manifold Pressure Measurement Detail

Following steps and diagram indicate location of the

connection points required to measure manifold pressure.

Manifold pressure may be measured using a U-Tube

Manometer or Differential Pressure Gauge. Diagram shows

connection of both measuring devices. Only ONE DEVfCE [S

REC:)UIREDto measure manifold pressure.

Remove plug. Install appropriate barbed fitting and connect

pressure side line from U-Tube Manometer or Differential

Pressure Gauge.

Refer to "Differential Air Pressure Switch Check - all

models" on page 45 when reading manifold pressure.

When measurement is complete, disconnect U-Tube

Manometer or Differential Pressure Gauge. Be sure to

reinstall 1/8"plug, using appropriate pipe thread sealant

approved for use with natural and liquefied Petroleum

gases.

PRESSURE REGULATOR

ADJUSTMENT

(UNDER COVER SCREW) ..............

................GAS VALVE VENT

OUTLET PRESSURE TAP

(1/8_'PLUG)

/

PRESSURE

CROSS CONNECTOR W/CAP

PRESSURE SWITCH

WHITE TRANSPARENT

VINYL TUBING

DIFFERENTIAL

PRESSURE

GAUGE

REFERENCE PRESSURE

'....... U-TUBE

MANOMETER

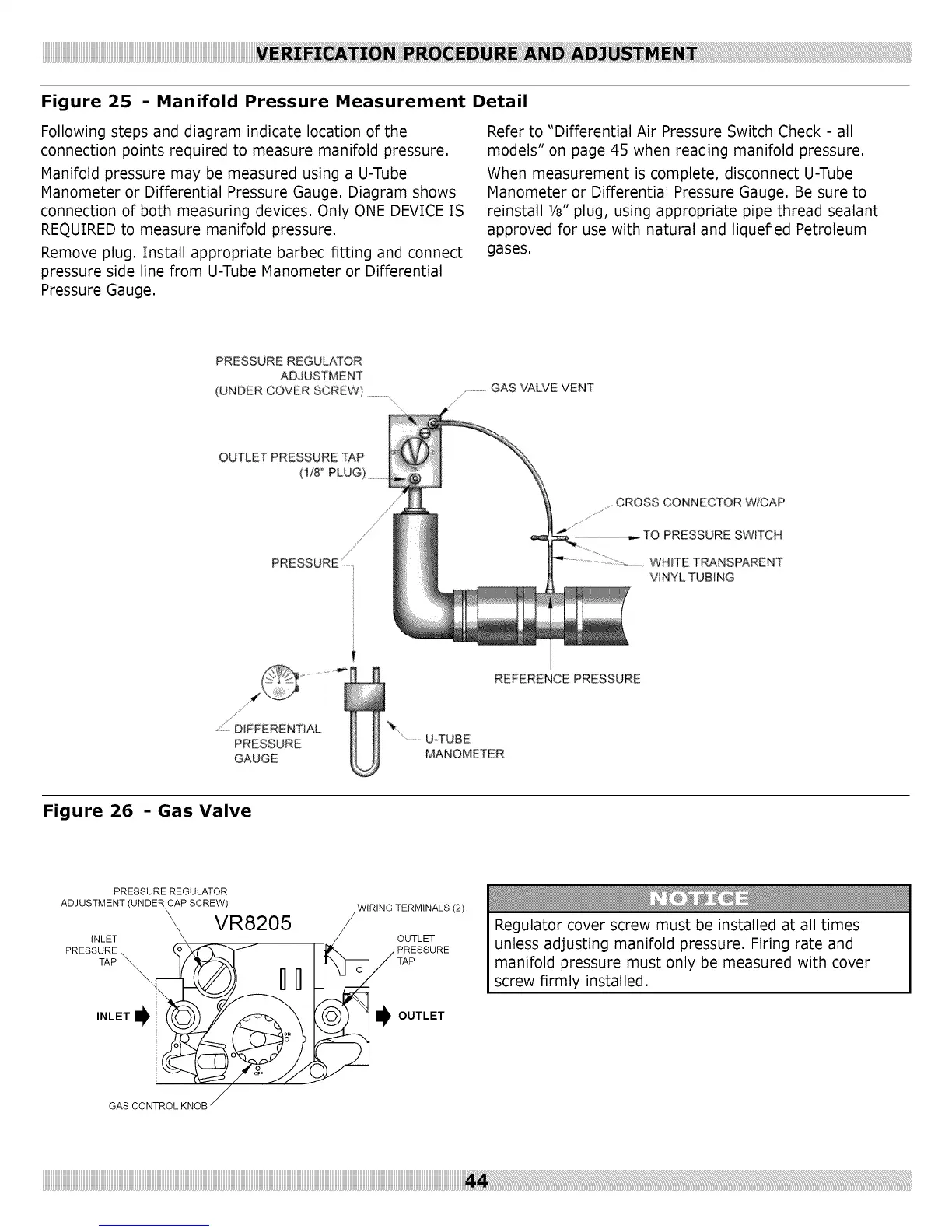

Figure 26 - Gas Valve

PRESSURE REGULATOR

ADJUSTMENT (UNDER CAP SCREW) WIRING TERMINALS (2)

VR8205

INLET OUTLET

PRESSURE PRESSURE

TAP _

INLET_ _ OUTLET

Regulator cover screw must be installed at all times

unless adjusting manifold pressure. Firing rate and

manifold pressure must only be measured with cover

screw firmly installed.

GAS CONTROL KNOB

Loading...

Loading...