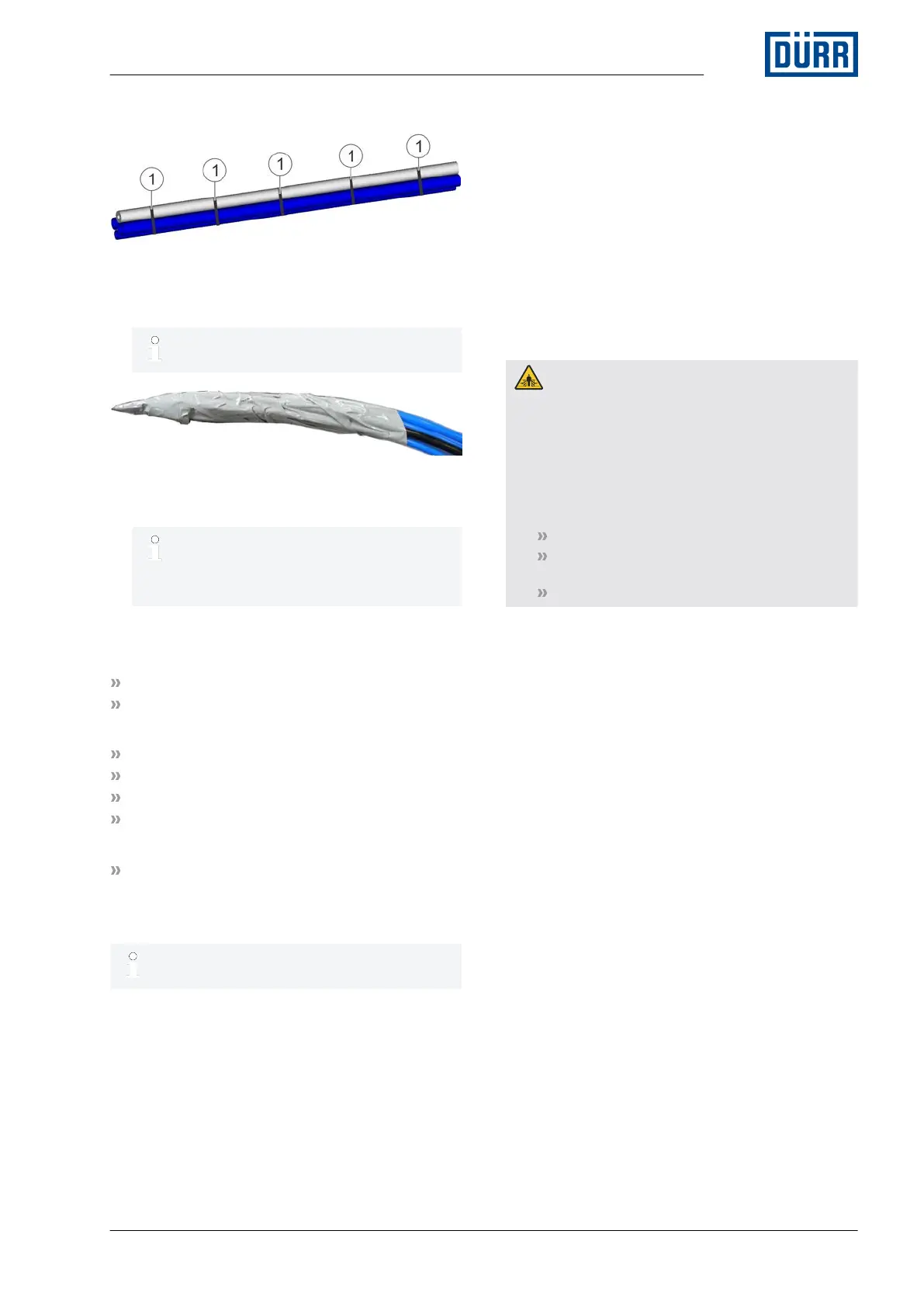

Fig. 7: Fixing Hose Package (Example)

3.

Fix ordered hose package at a distance of 1m

with a Velcro tape (1).

Remove Velcro tapes (1) when inserting

into the convoluted hose.

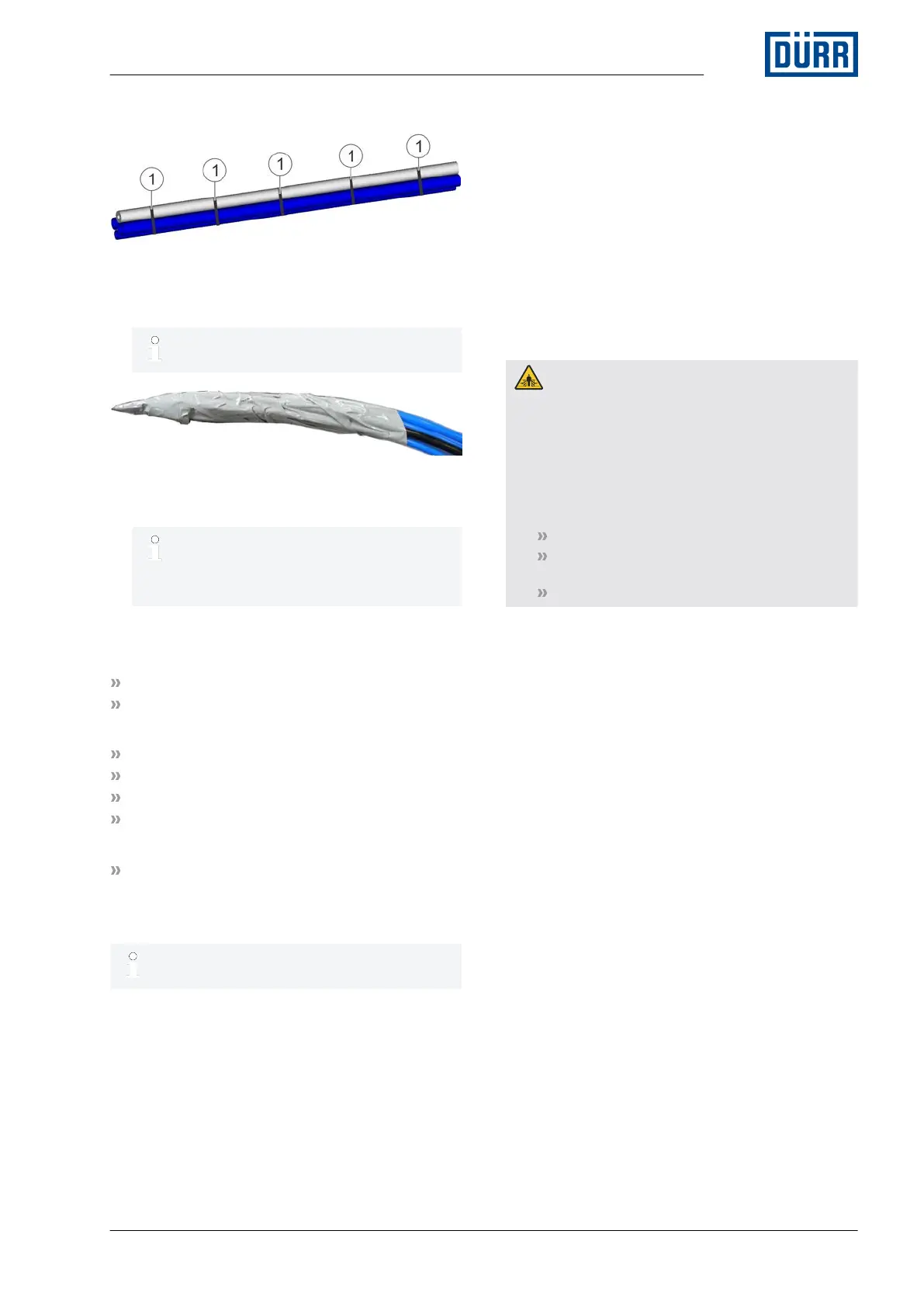

Fig. 8: Binding Hose Ends (Example)

4.

Bind hose ends together with adhesive tape.

Optionally fasten a pull wire to the hose

ends. Using the pull wire makes it easier

to pull in the hose package into the con-

voluted hose.

4.5 Inserting the Hoses

Personnel:

Mechanic

+ additional qualification explosion protection

Protective equipment:

Eye protection

Protective workwear

Protective gloves

Anti-Static Safety Boots

Requirements:

Convoluted hose is disassembled from the

robot.

Follow “Cat track A1- A6” operating instructions

Ä “Applicable documents”.

A pull wire facilitates pulling in the hose

package.

1.

Push cord through the sleeve of the support

bracket.

2.

Push cord into the convoluted hose.

3.

Push hoses up to the first Velcro tape in the

convoluted hose. Remove Velcro tape.

4.

Push hoses up to the next V

elcro tape in the

convoluted hose.

5.

Remove next Velcro tape.

6.

Repeat the process until the hose projects out

of the convoluted hose by about 30 cm.

7.

Mount convoluted hose on the robot by means

of the hose clips.

Follow “Cat track A1- A6” operating instructions

Ä

“Applicable documents”.

4.6 Assembling Convoluted Hose

WARNING!

Danger of crushing from robot movements

Robots move at high speeds and high power. If

the robot catches hold of persons, it can cause

life-threatening injury or death.

– Make sure that no people are in the danger

zone of the robot during operation.

– Before carrying out any work:

Moving robots in maintenance position

Switch off the mains disconnecting device

on the technology cabinet.

Secure against reconnection.

Assembly

03/2019 Atomizer Connection EcoGun - MRS00004EN 11/

24

Loading...

Loading...