DC 3800 Stat - 10

Part No 9443-A

Technical Data

50 Hz/60 Hz

HxWxL fl oorconstruction 1400x400x860 mm

HxWxL wallconstruction 1440x400x790 mm

Weight 50 kg/50 kg

Inlet 50 mm/ 50 mm

Collection in bag/container 30 l/40 l

Max Temp 130°/130°

Flow, max 260 m

3

/h/320 m

3

/h

Neg. pressure, max 28 kPa/30 kPa

Power consumption 2.2 kW/3 kW

Manual reverse pulse

fi lter cleaning

Fine fi lter polyester, area 1.8 m

2

1.8 m

2

Degree of separation

> 99,9 %/> 99,9 %

A fi ne fi lter, polyester (Part No 42025), is mounted in the

machine. A HEPA fi lter is available as optional equipment.

Soundlevel <75 dB(A)/<75 dB(A)

Filter Cleaning with Reverse Pulse

Compressed air 4 l/s, 4 bar

Connection, hose 6/8 mm

El connection 24 V DC, 12 W

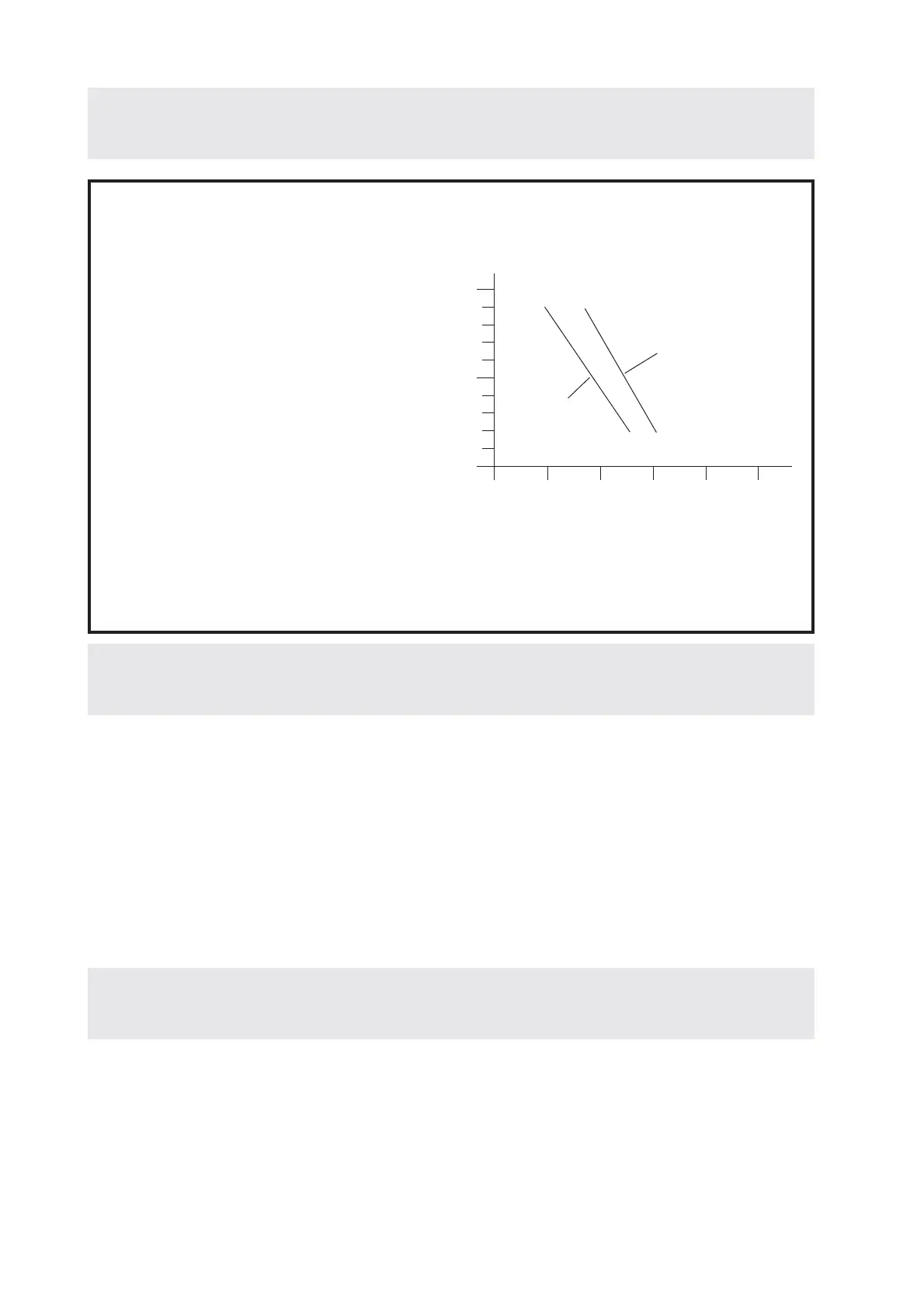

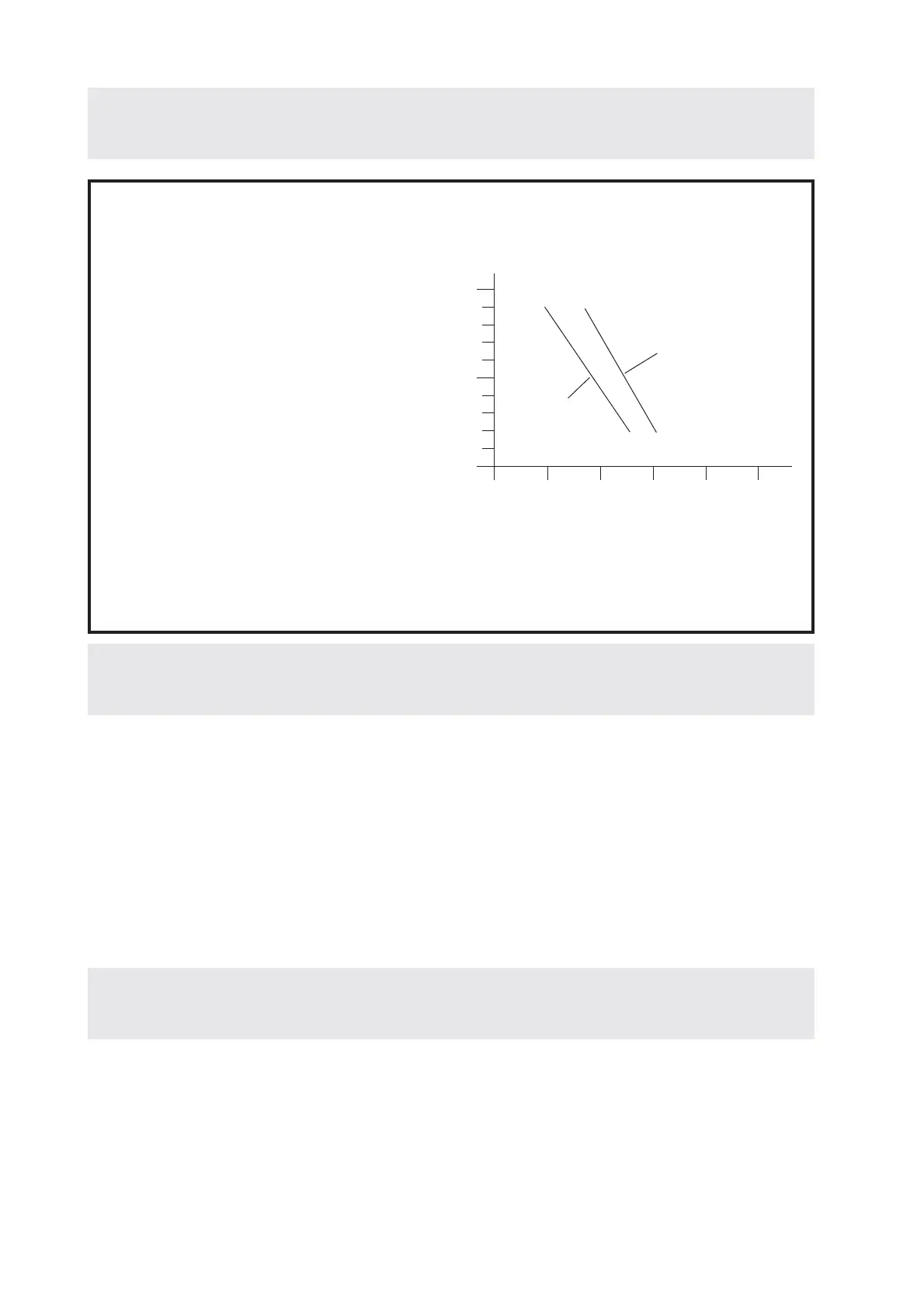

kPa

20

10

100 200 300 400 m

3

/h500

Vacuum producer

capacity

DC 3800

2.5 kW 50 Hz

DC 3800 3.0 kW 60 Hz

The DC 3800 Stationary is a dust extractor suitable

for the extraction of dust, powders and chips and

also for cleaning.

The fi lter is cleaned with air pulse against the

fl ow of extracted air. This arrangement provides

for very effective cleaning while at the same time

giving long fi lter life.

The dust laden air is introduced into the units cyclone

where most of the dust is separated by the cyclonic

action of the air. This dust falls to the bottom of the

cyclone where it is emptied into a plastic sack. The air

then passes through the fi ne fi lter and is exhausted

through the pump. HEPA fi ltration is available as an

option.

The vacuum is produced by an motor driven turbo-

pump. The turbopump is a regenerative blower where

a direct driven impeller rotates in the pump housing.

The tolerances of the unit are very small so that it is

possible to attain the highest effi ciency. Because the

pump compresses the air, it is natural that it becomes

hot while running.

Description

Installation

of 4 l/s, 4 bars and a control voltage of 24 V DC,

12 W (which should be taken from the control box).

Connect the tubing system to the inlet and outlet of

the machine. Install and tighten a plastic sack under

the cyclone.

The machine should be equipped with a suitable

electrical starter and installed by a certifi ed electri-

cian. The unit should be equipped with a lockable

disconnect.

Assemble the fi lter unit. Mount it on the fl oor. Con-

nect the tubing to the inlet and outlet. Connect the

fi lter cleaning module to a compressed air supply

Loading...

Loading...