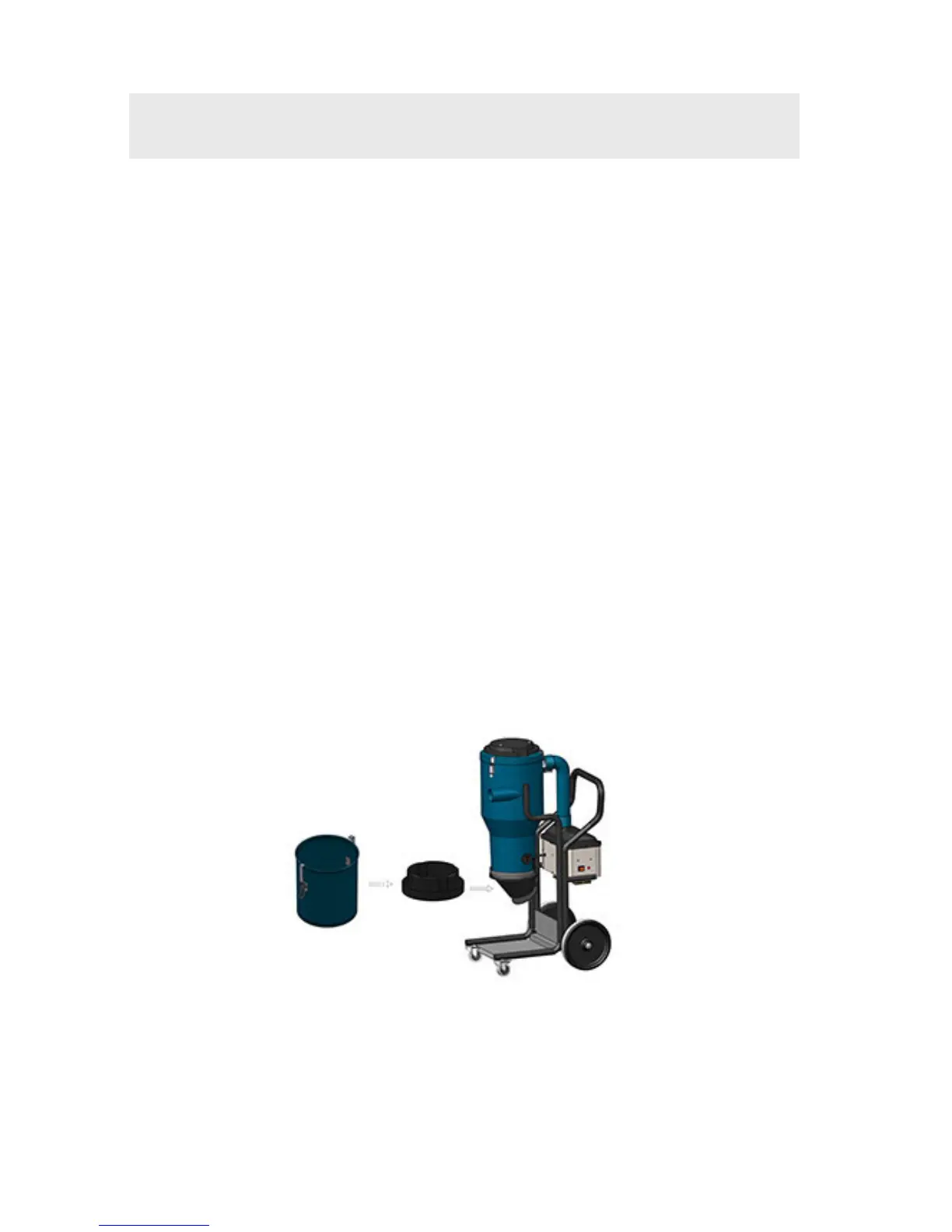

The DC Tromb 400 is stable, tough and reliable

and particularly suited to spot extraction where

plenty and easy dust is created. The DC Tromb

400 is used for source extraction (with a maximum

constriction of Ø15 mm) in many situations, such

as grinding, welding, personal decontamination,

and cleaning.

The DC Tromb 400 is driven by 2 single phase,

two stage fans.

The extraction system functions with negative

pressure (vacuum) that draws the air through suc-

tion casings/nozzles, hose system, separator and

lter system. Coarse separation of dust occurs in

the units cyclone which is a highly ecient sepa-

rator for larger particulate. The ne dust is sepa-

rated and contained by the lter system. There is

a jacket mounted at the top of the lter cartridge

protecting it from the dust as it enters the cyclone

from the hose. Reverse pulse lter cleaning gives

long lter life and a consistently high suction capa-

city. The machine is equipped with a HEPA lter.

DC Tromb 400a

The machine is equipped with a container that can

be tted with a plastic bag. The extracted material

can then be easily recycled or disposed of.

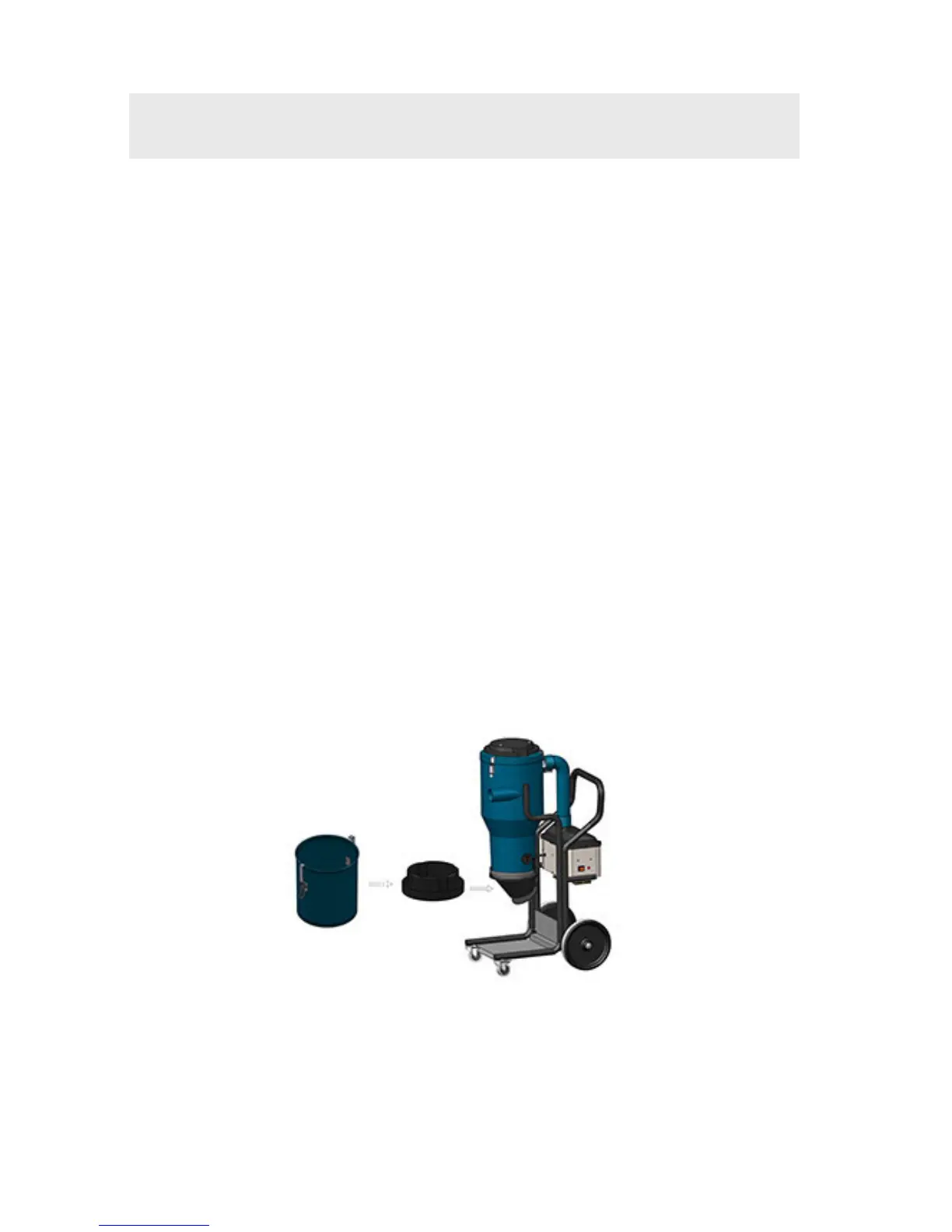

DC Tromb 400c:

Material which has been extracted and separated

is collected in a plastic sack. The sack can be

removed with a simple hand grip. The collected

material is easily handled in this way for disposal

or recycling.

DC Tromb 400L:

The machine is equipped with a exible bag sys-

tem, in which the dust is collected in a permanently

closed system.

Description

a

L

c

Loading...

Loading...