exceed 3 mW/cm

2

of UVA light, and also include the more dangerous UVB light (primarily responsible for

suntans, sun burns, and skin cancer) as well.

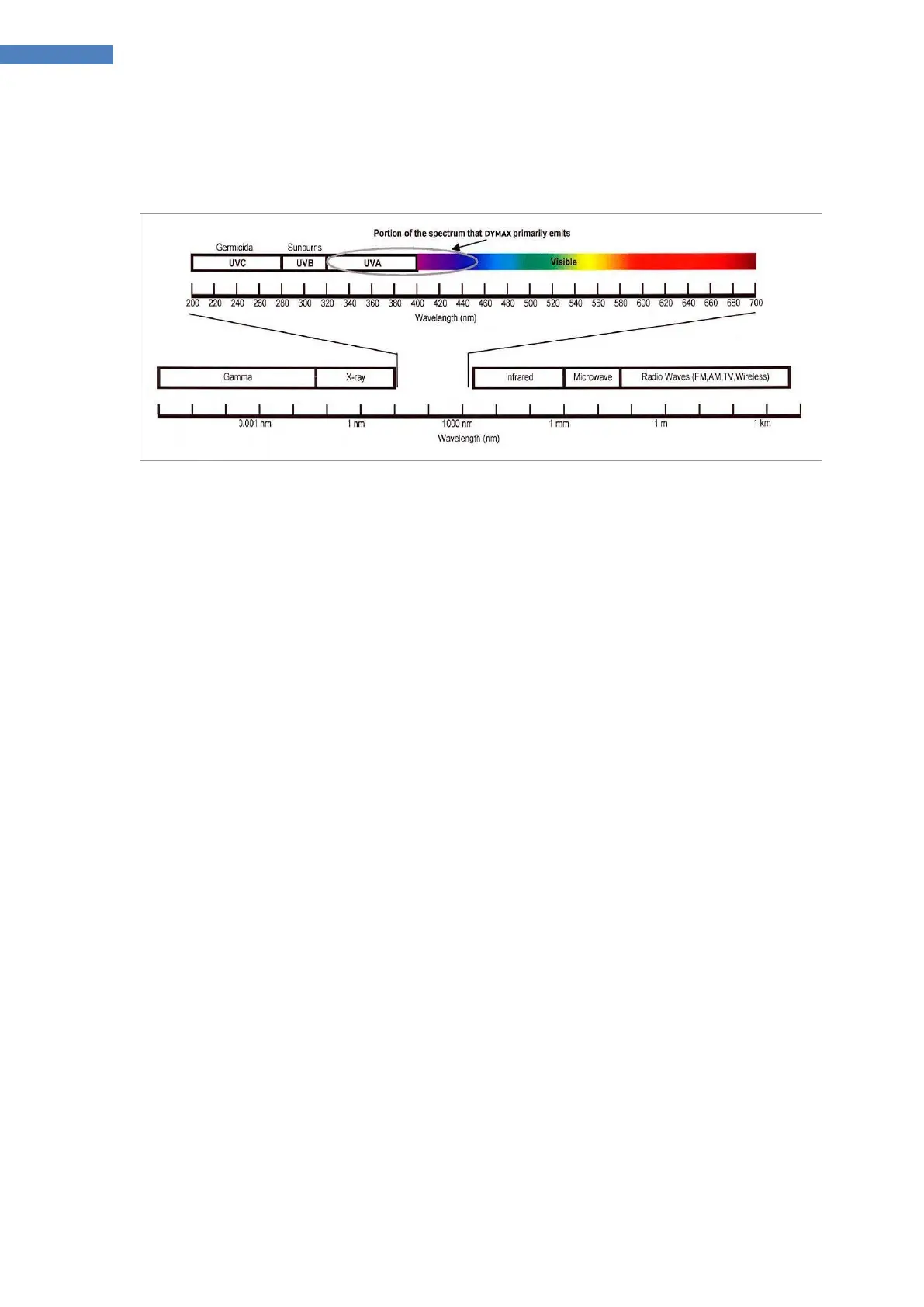

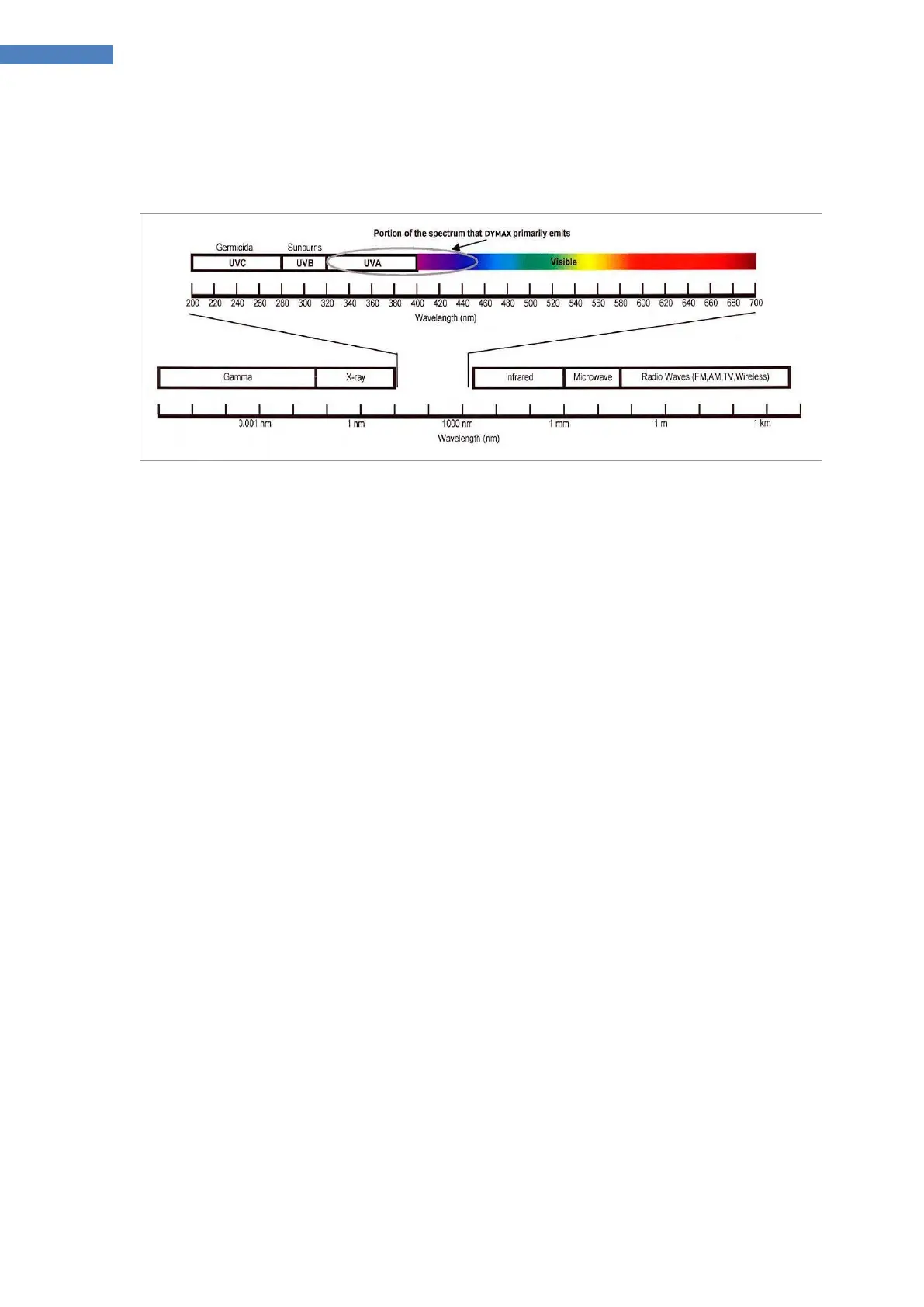

Figure 1. UV Spectrum

Checking the Workstation

The human eye cannot detect "pure" UV light, only visible light. A radiometer should be used to measure

stray UV light to confirm the safety of a UV light-curing process. A workstation that exposes an operator to

more than 1 mW/cm

2

of UVA continuously should be redesigned.

Protecting Operators

Light-curing technology can be a regulatory compliant, "worker-friendly" manufacturing process when the

proper safety equipment and operator training is utilized. There are two ways to protect operators from

UV exposure: shield the operator and/or shield the source.

UV-Blocking Eye Protection — UV-blocking eye protection is recommended when operating UV light-

curing systems. Both clear and tinted UV-blocking eye protection is available from Dymax.

UV-Blocking Skin Protection — Where the potential exists for UV exposure upon skin, opaque, UV-

blocking clothing, gloves, and full-face shields are recommended.

Shield the Source of UV

Any substrate that blocks UV light can be used as a shield to protect workers from stray UV light. The

following materials can be used to create simple shielding structures:

Rigid Plastic Film — Transparent or translucent/UV-blocking plastics (typically polycarbonate or acrylic)

are commonly used to create shielding where some level of transparency is also desired.

Flexible Film — Translucent UV-blocking, flexible urethane films can be used to quickly create

workstation shielding.

Ozone

Standard Dymax bulbs (UVA type) generate an insignificant amount of UVC and therefore essentially no

ozone. Some UV light-curing systems, like those used to cure UV inks, emit primarily “shortwave” (UVB

and UVC) energy. Upon exposure to UVC light (specifically <240 nm), oxygen molecules (O

2

) split into

oxygen atoms (O) and recombine with O

2

to create ozone O

3

.

Loading...

Loading...