then the adjustment screw must be turned -87.6 degrees

(negative = ccw rotation as viewed from the rear of the

instrument) or about ccw 1/4 of a full turn to bring it back

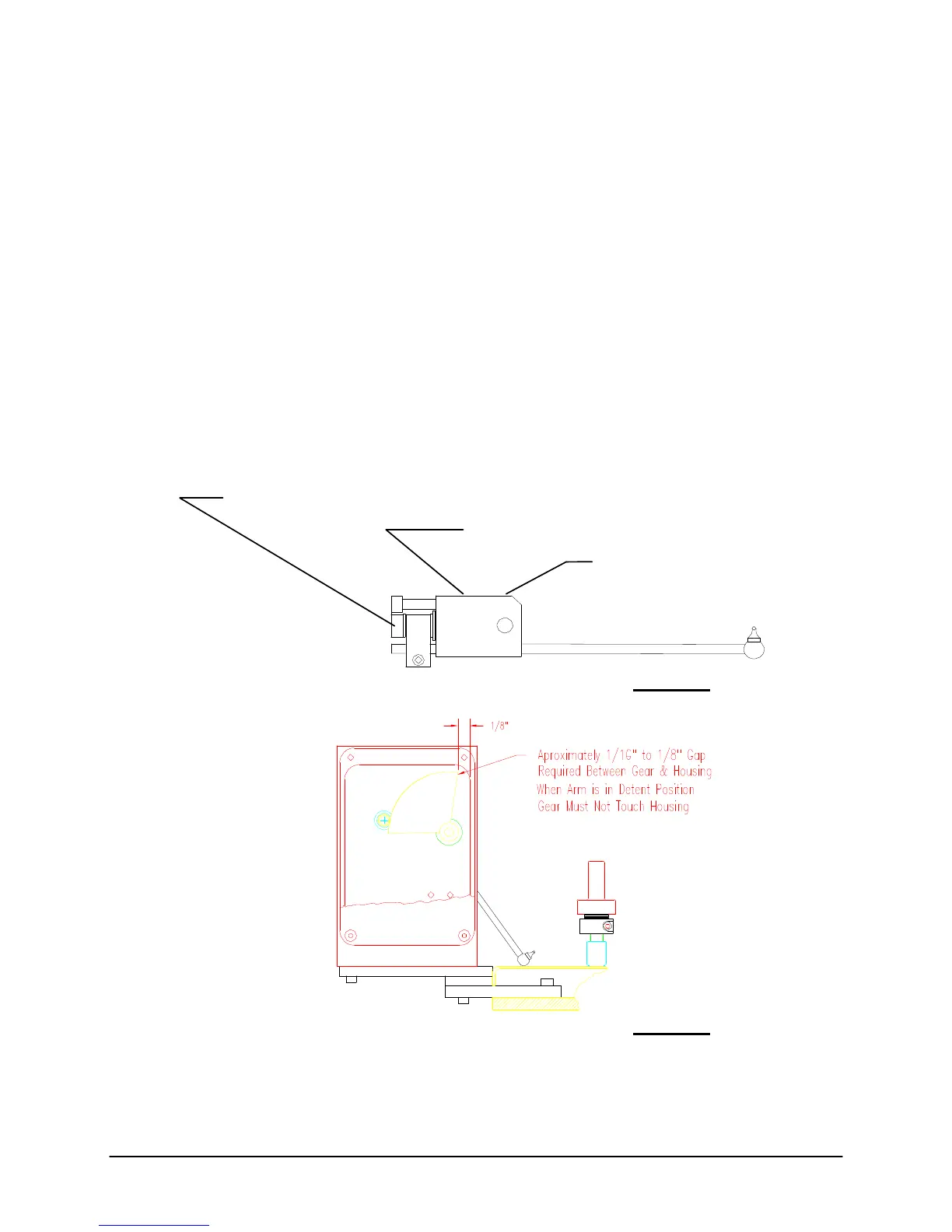

into calibration per ASTM requirements. Use a 1/8" Allen

Wrench to turn the adjustment screw.

5. Recheck the encoder calibration by repeating the

micrometer measurements in steps 2 & 3. If further

adjustment is required then again use Table 1 to determine

the appropriate degrees of movement. Repeat this process

until the arm is calibrated. Once the arm is calibrated,

secure the arm in place by re tightening the second arm set

screw (see Figure 1). Apply removable thread locker

(Loctite

type 290 or equivalent). Reinstall the cover and

tighten all hardware.

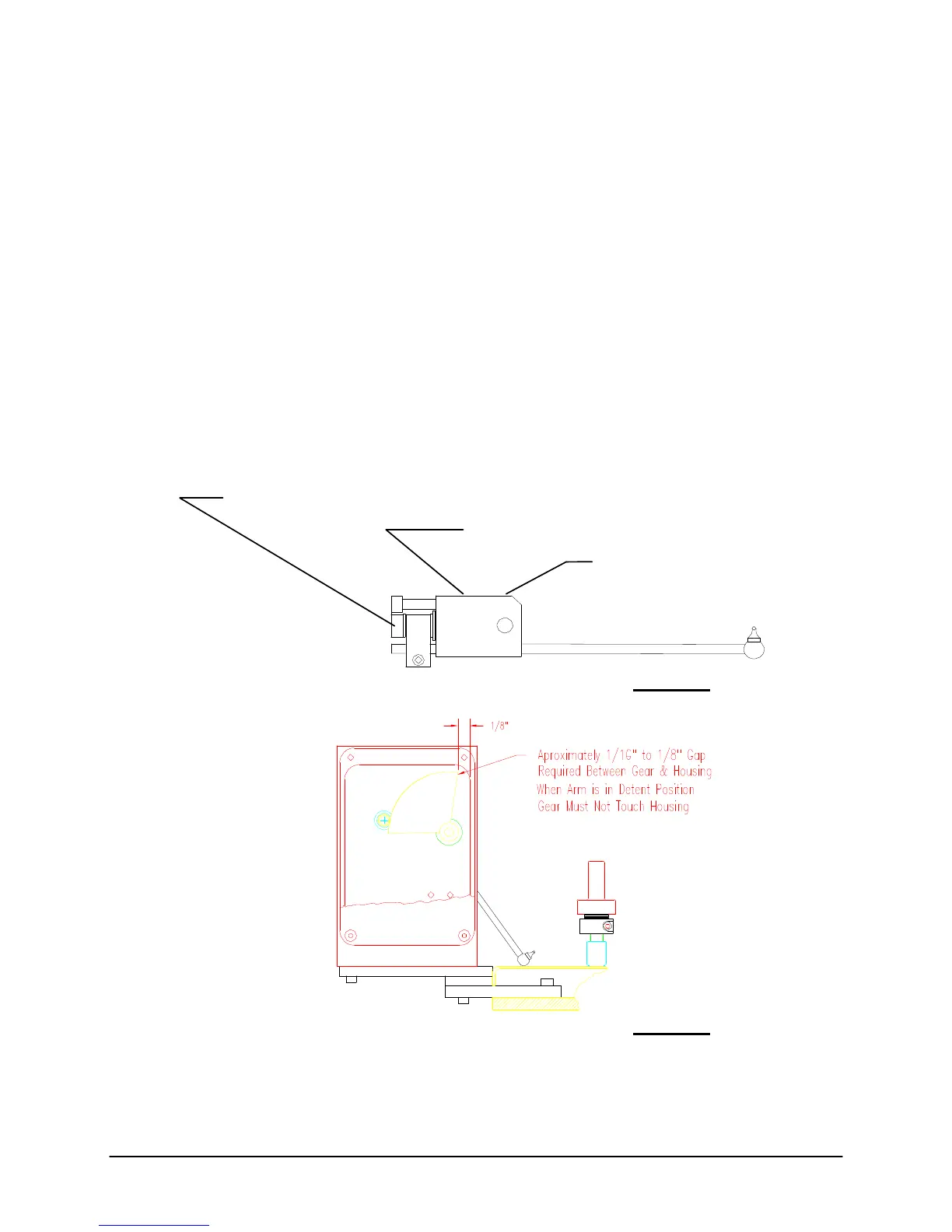

ADJUSTMENT SCREW: TURN CW TO EXTEND ARM

TURN CCW TO RETRACT ARM

SECOND SET SCREW LOCKS ARM IN PLACE

LOOSEN THIS SET SCREW TO CALIBRATE ENCODER

FIRST SET SCREW SECURES

ARM TO SHAFT

DO NOT LOOSEN THIS SET SCREW!

Figure 1

Figure 2

Series 4000 Melt Indexer Operation Manual The Digital Encoder: Use and Calibration

56

Loading...

Loading...