4

Instruction Leaflet IL29C204I

Eective October 2011

Installation Instructions for Motor Operator for

3- and 4-Pole ND, NB, NC, MD, MA, MC Type

Circuit Breakers and Molded Case Switches

EATON CORPORATION www.eaton.com

,

.

Whits

d

-

-

DC

LEGEND

-

On

Switch

-

Switch

52a

-

Switch

-

Breaker Auxiliary

Switch

DIAGRAM

SHOWS

THE CIRCUIT

AND

MOTOR

OPERATOR

IN

‘OFF’ POSITION.

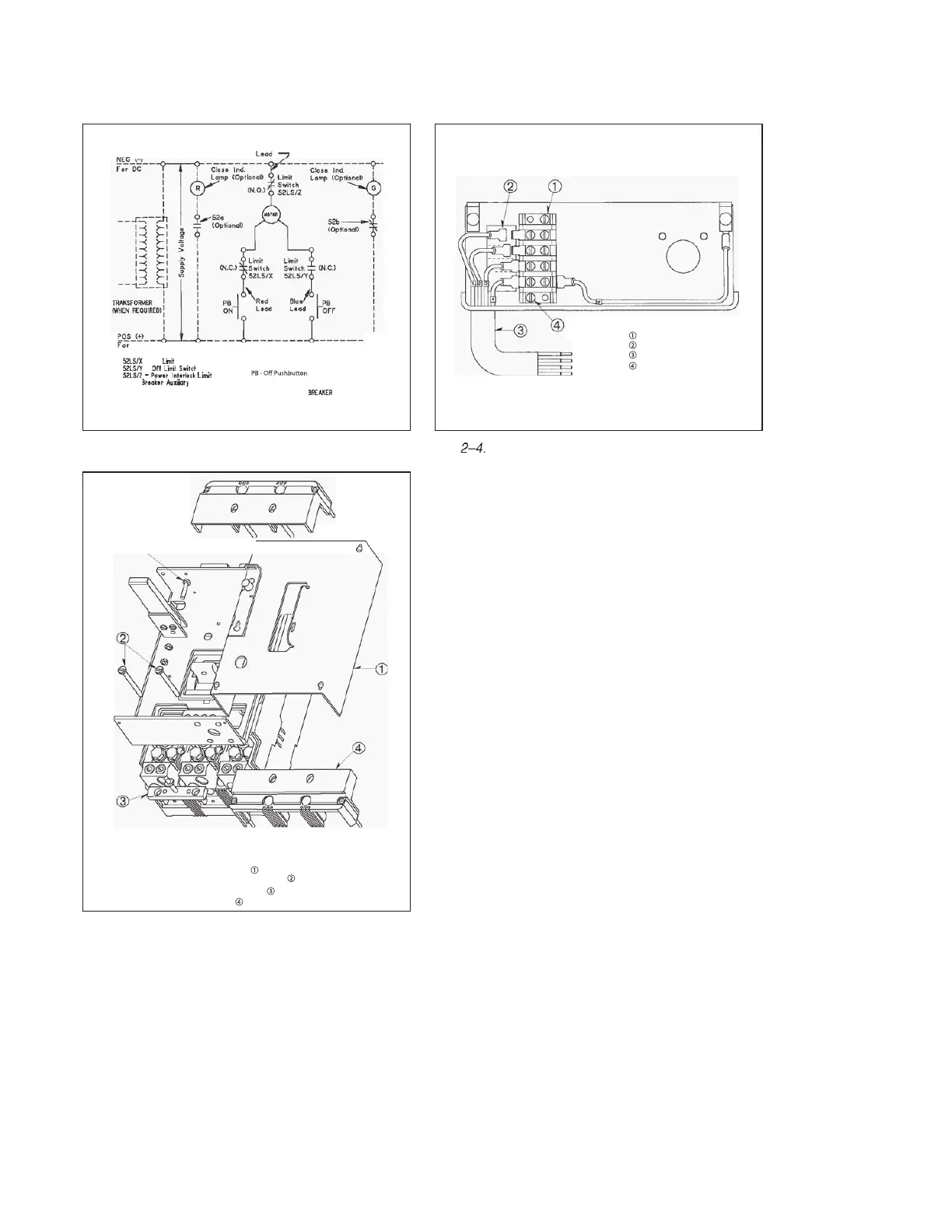

Fig.

2

-

2.

Motor Operator Wiring Diagram

The Head

of

the

Screw

Towards

“ O N ”

Direction

For tighting breaker cable boflom terminals

use

the

following steps:

1.

Remove the motor operator cover

2.

Loosen

two

4

in. pan head mounting screws

3.

Remove bottom mounting plate spacer

4.

Remove bottom terminal cover

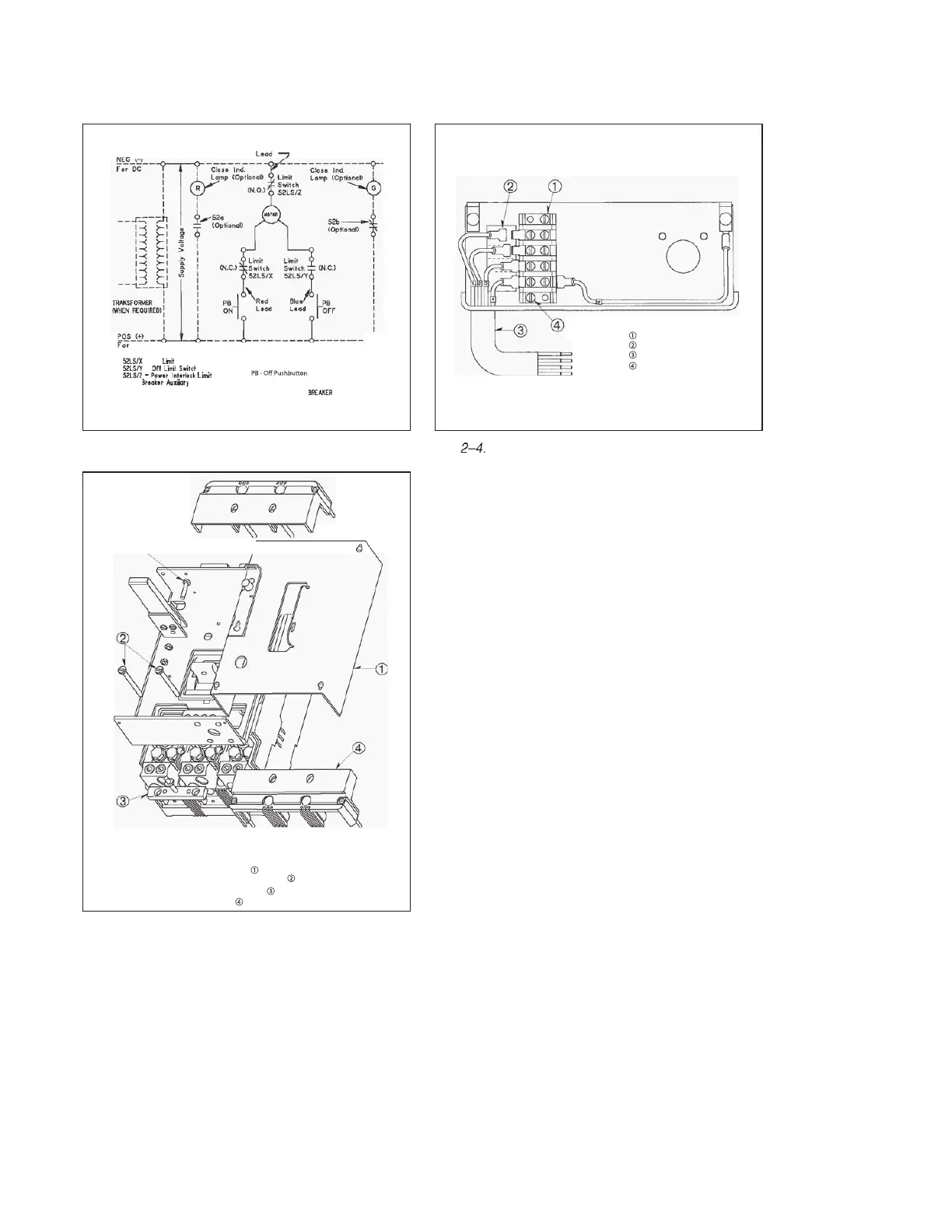

Terminal

Block

Wire Connector

Terminal Screws

Wire Leads

Fig. Terminal Block and Wire Leads

supplied. Put the bottom mounting plate (spacer)

between the motor operator and the breaker

(Figs. 2

-

3 (lt.03)). The roll pin must be in the

base slot and the push nut inside the operator. Use

two 4

-

in. pan head screws. The handle extension

must be between the rollers of the bracket assem

-

bly, and the motor towards the line end of the

breaker (Figs. 2

-

3, 4

-

1).

2

-

5.

2

-

6.

2

-

7.

2

-

8.

The motor operator is equipped with a “PUSH

-

TO

-

TRIP” feature. Turn circuit breaker “ON”. Press the

“PUSH

-

TO

-

TRIP” button to verify that the breaker

trips. Reset breaker and turn “ON” again. Replace

the cover and cover screws, check the “PUSH

-

TO

-

TR

I

P” again

.

The motor operator is equipped with a terminal

block and 30

-

in. long wire leads. If it is desirable to

change wire leads, just pull out the wire connector,

and connect the new wire leads to the screws or

tabs of the terminal block. (See Fig. 2

-

4 page 3.)

If motor operator is used for

NB,

NC, or MD, MA,

MC type circuit breakers and molded case switches

the mounting screws must be changed to .190 x

3.375, .190 x 3.625, or .190-32 x 2.25, .190-32 x

1.75 pan head screw with lock washer.

To connect the power and control wiring, refer to

Fig. 2

-

2, page 3.

Fig.

2

-

3.

Terminal Tightening Instructions

P B - O n P u s h b u t t o n

52b

}

Momentary Contacts

Loading...

Loading...