Electrical closing – motor-operated low voltage

closing solenoid/nova reclosers

WARNING

Hazardous voltage. Solidly ground all equipment.

Failure to comply can result in death, severe personal

injury, and equipment damage.

T223.2

High-voltage is not required for reclosers utilizing a motor-

operated closing mechanism, low voltage closing, or NOVA

recloser. For information on energizing the recloser, refer

to the appropriate recloser installation manual. Low voltage

supply can use either 120 or 240 VAC for input power.

Check the name plate on the recloser to verify the correct

closing power requirements.

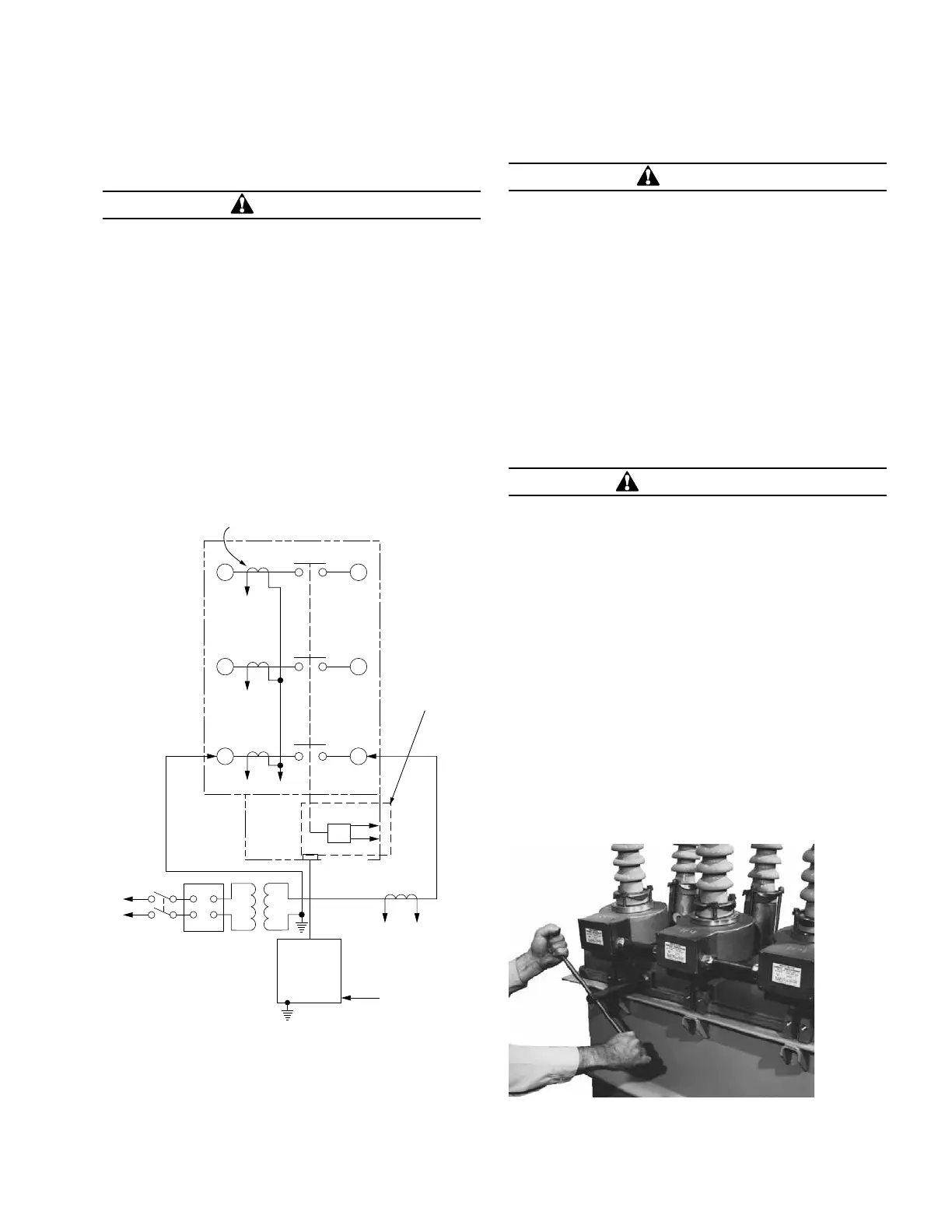

Figure 41 shows a test circuit for motor-operated,

low-voltage solenoid-closing, and NOVA reclosers. Since

these reclosers require only a low voltage source for

closing, high-voltage transformer T3 and its protective cage

is eliminated. All other equipment is the same as the test

equipment shown in Figure 40.

65

43

21

FORM 4D

RECLOSER

CONTROL

J

G K

H

X W

120/240 VAC

POWER

SUPPLY

T1 T2

240 VAC

VARIABLE

AUTOTRANSFORMER

240 VAC-20 A

AC POWER

TO AMMETER

AND RELAY

TO OPERATE

CYCLE

COUNTER OR

OTHER TIMING

DEVICE

SENSING CTs (3)

NOT APPLICABLE FOR

CONTROL-POWERED

NOVA RECLOSERS

Figure 41. Suggested test circuit for motor-operated,

solenoid-closing reclosers with low-voltage closing

Manual closing – solenoid-operated reclosers

WARNING

Explosion Hazard. Excessive Contact Arcing. Do not use

the manual closing tool to close an oil-insulated energized

recloser. Closing an energized oil-insulated recloser with

a manual closing tool can cause excessive contact arcing,

rapid build-up of gas within the equipment, and possible

explosion which can cause death, severe personal injury,

and equipment damage.

T203.2

If high-voltage for operating the closing solenoid is not

available, manual closing can be substituted for electrical

closing. However, not all control settings can be checked

since manual closing is not synchronized with the closing

coil control circuit in the control.

Follow these steps to manually close the recloser:

1. Remove the closing tool port cover and gasket from the

side of the recloser head casting.

CAUTION

Equipment damage. Do not turn the manual closing tool

more than one-quarter turn clockwise. Forcing the tool

beyond the mechanism stop may shear the pin on the

closing shaft of the recloser.

T222.0

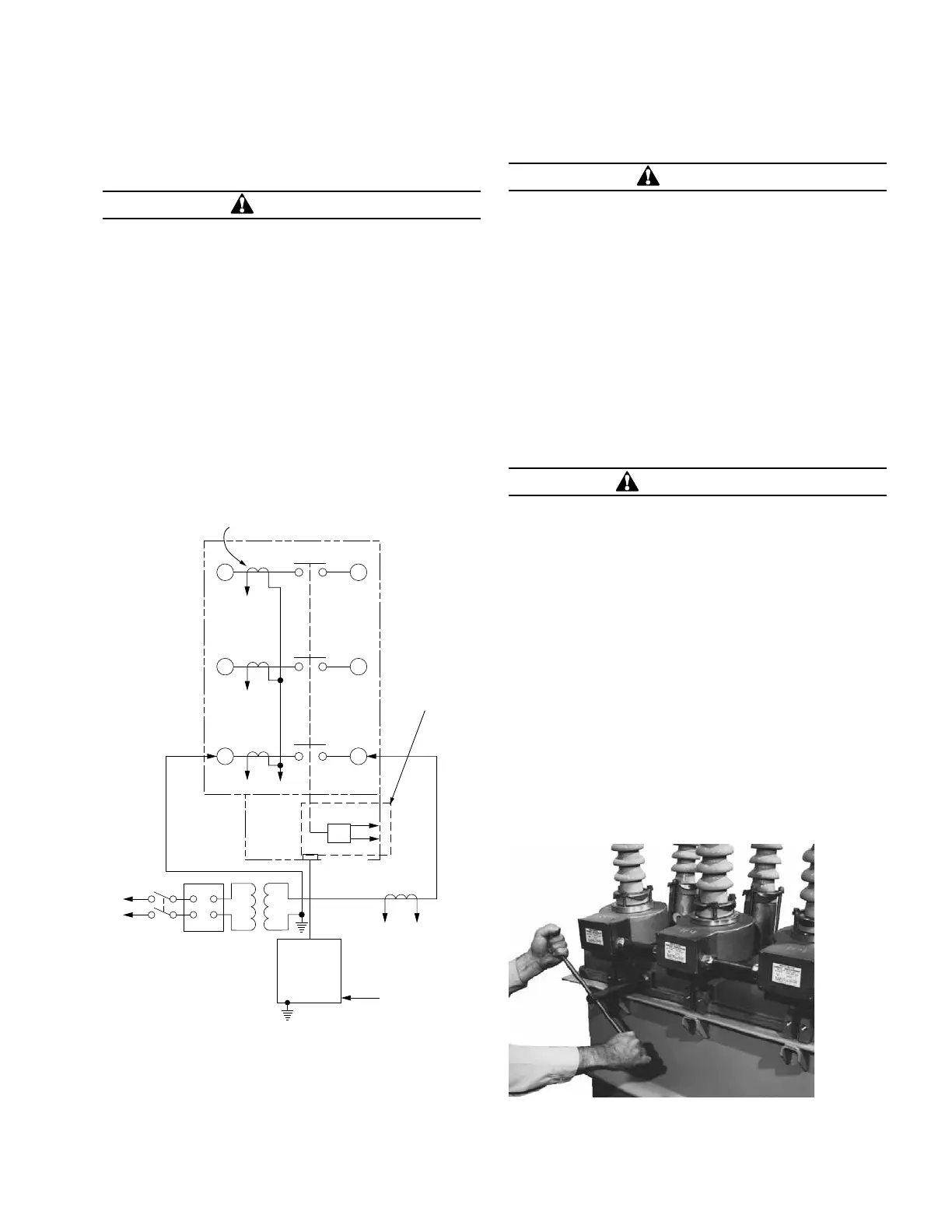

2. Insert the tee-handled tool (available as an accessory)

into the port, engaging the pin on the closing shaft

(Figure 42).

3. Close the recloser by placing the yellow operating

handle (located under the sleethood) into the up

or CLOSED position and turning the closing tool

one-quarter turn clockwise.

4. After each trip operation, about 1/2 second elapses

while the closing solenoid plunger is moving upward to

reset the main toggle latch.

5. After the main toggle latch resets, the recloser can be

closed again by operating the manual closing tool.

6. Replace the gasket and port cover on the recloser head

after testing has been completed.

Figure 42. Using a manual closing tool to operate

therecloser

41OPERATION INSTRUCTIONS MN280049EN September 2017

Form 4D Microprocessor-based pole-mount recloser control installation and operation instructions

Loading...

Loading...