Battery charging

If it is not possible to charge the battery with the control’s

built-in charger, a KME5-60-1 (120 VAC) portable bench

type battery charger kit is available, which includes the

KA43ME7001 Battery Charger and the KME5-325-1 Adapter

Cable. Refer to S280-79-14 KA43ME7001 Portable Lead Acid

Battery Charger Instructions for additional information.

IMPORTANT

Do not attempt to charge a lead acid battery below 2

VDC with the KA43ME7001 charger. The charger requires

a minimal voltage to sense a battery is connected.

If the lead acid battery is below 19 VDC for over 2 days,

replace the battery. The expired battery should be

disposed of in an environmentally responsible manner.

Consult local regulations for proper battery disposal.

Charge the battery with a KA43ME7001 (120 VAC) portable

charger as applicable:

Form 4D Pole-Mount Recloser Control (Standard

Capacity) – Connect the battery directly to the

KA43ME7001 charger. The charger continuously

monitors the battery voltage.

Form 4D Pole-Mount Recloser Control (High Capacity)–

Use adapter KME5-325-1 to connect the two 12 volt

batteries to the KA43ME7001 charger.

IMPORTANT

Never connect a single 12 volt battery to the

KA43ME7001 charger. Use adapter KME5-325-1 with the

battery assembly when connecting the charger to the

two 12 volt batteries.

ote:N A yellow LED indicator on the body of the charger

illuminates when charging. A green LED indicator

illuminates when the charge is complete.

The charger senses when the battery voltage reaches

2.27 volts per cell, then the charge rate reduces to maintain

a trickle charge.

The yellow LED flickers to indicate the battery has reached a

full charge. This process can take up to 24 hours.

Refer to Table 17 for additional battery charging accessories.

Table 17. Battery charging accessories

Description Catalog number

120 VAC Battery charger for spare batteries . . . . KME5-60-1

Form 4D battery replacement procedure

The 24 VDC control battery has a life expectancy of four

years. It is recommended that the battery(s) be replaced

after four years or if the battery(s) fails a battery test (after

sufficient recharge time) - whichever occurs first.

ote:N Battery life is decreased at higher temperatures.

This procedure applies to a control with one or two

batteries.

1. Follow all locally approved safety procedures.

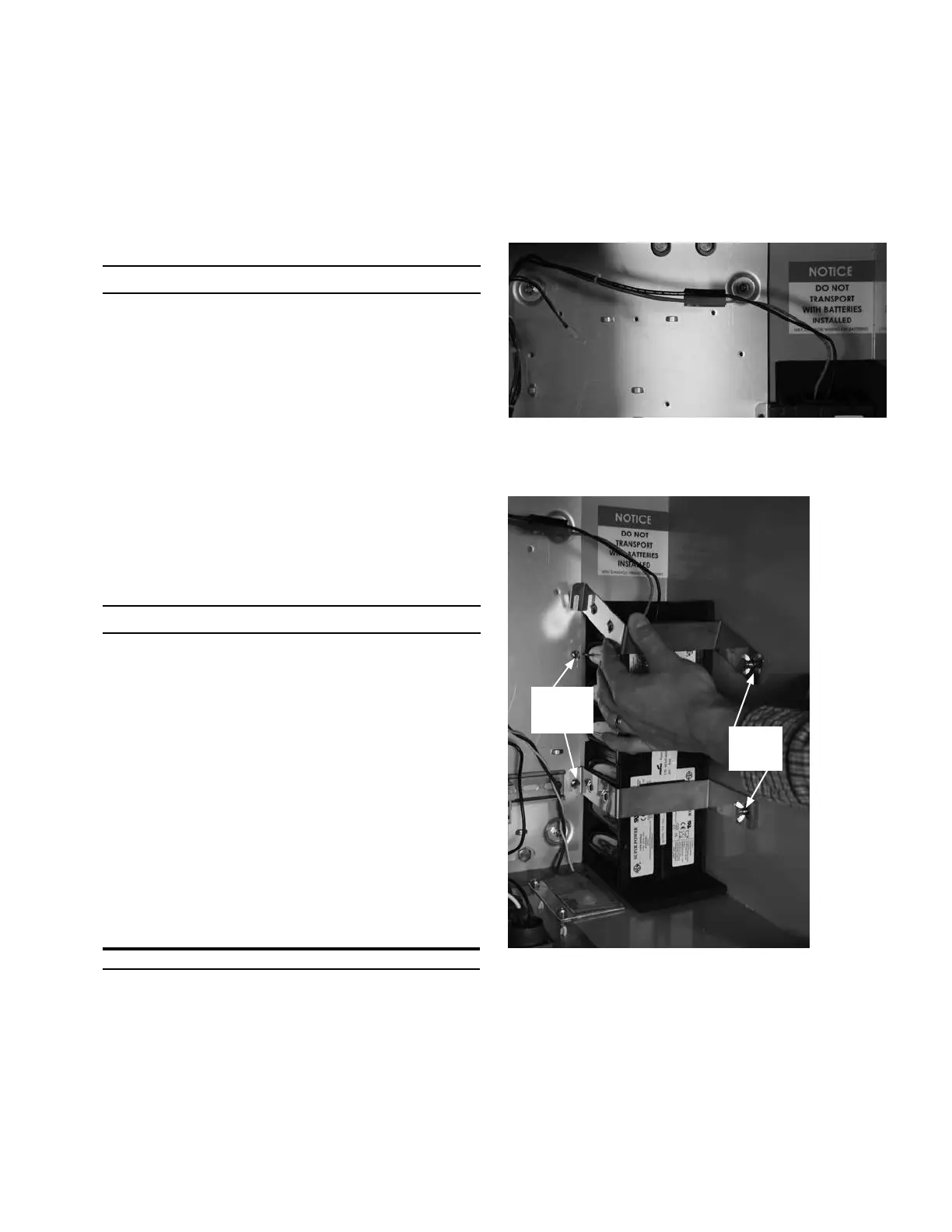

2. Disconnect the control wiring to the battery(s) that will

be replaced (Figure 44).

Figure 44. Battery connector

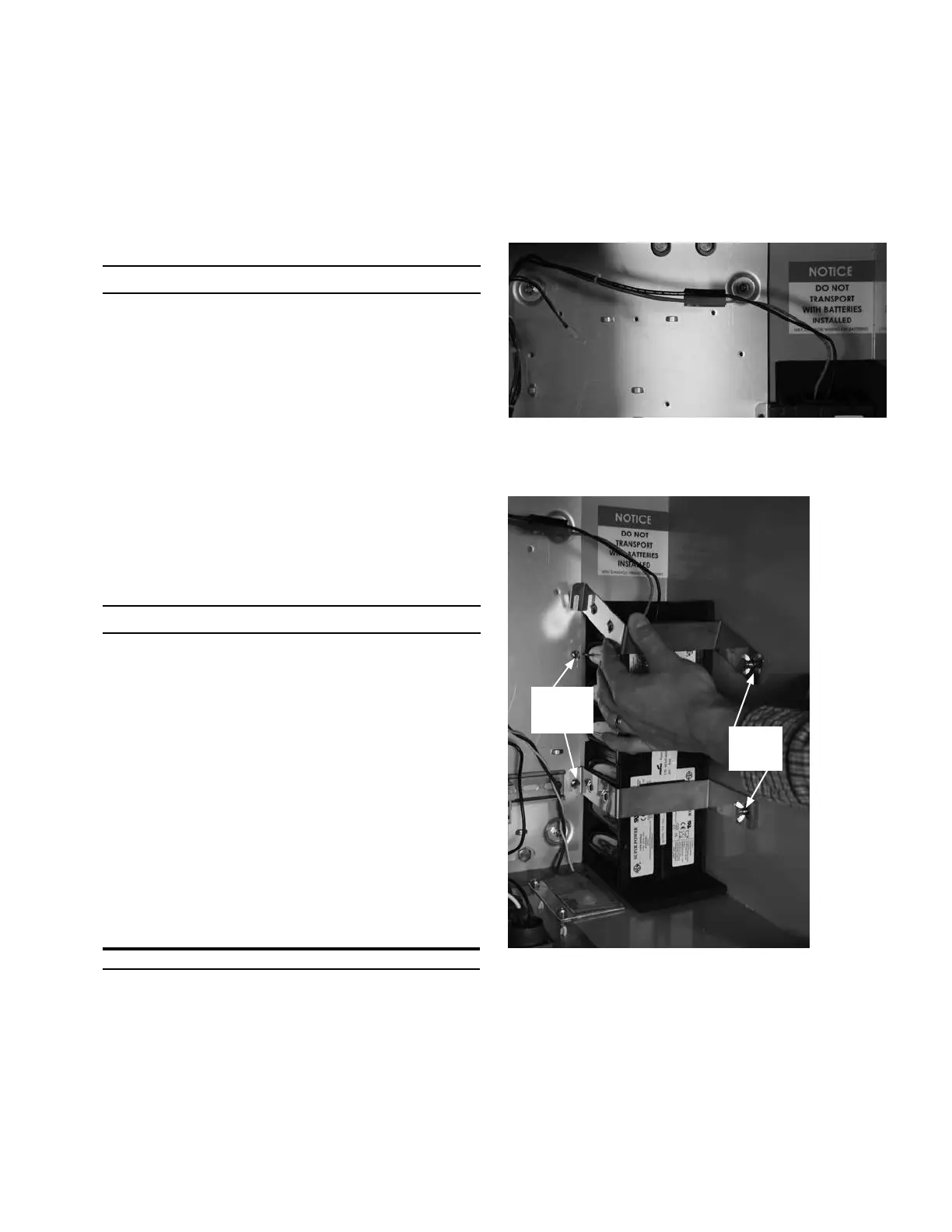

3. Loosen, but do not remove, the battery bracket two wing

nuts located to the front-right of battery (Figure 45).

Thumb

Screws

Wing

Nuts

Figure 45. Loosen and lift battery bracket

4. Loosen, but do not remove, the two thumb screws for

the battery brackets [located to the back-left of battery]

(Figure 45).

5. Push up on the open notch end of the top battery

bracket to release one end as shown in Figure 45.

(continued on next page)

43OPERATION INSTRUCTIONS MN280049EN September 2017

Form 4D Microprocessor-based pole-mount recloser control installation and operation instructions

Loading...

Loading...