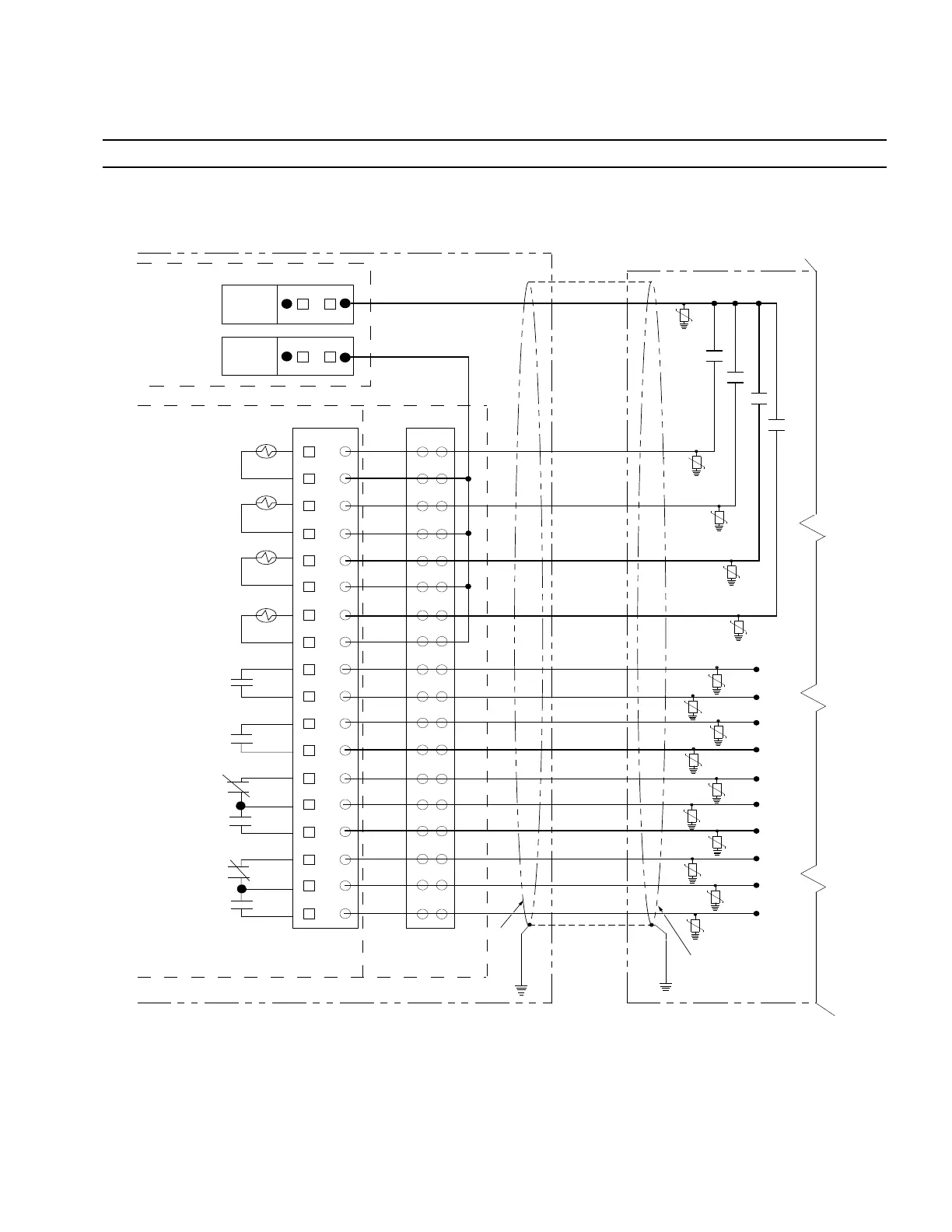

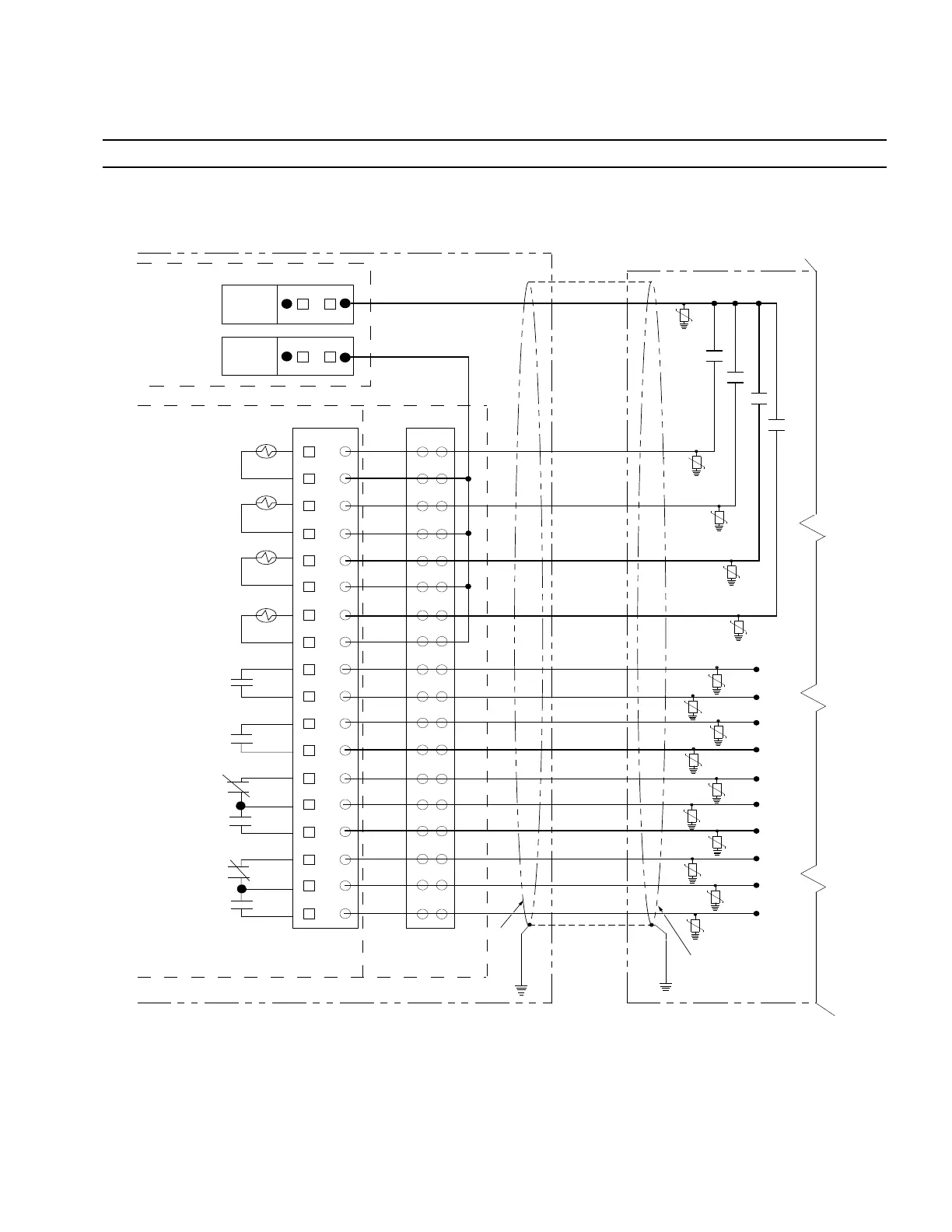

NOTICE

External leads must be shielded and the shield must be grounded at both ends. Terminate each lead with a 320VAC,

150 Joules metal oxide resistor (MOV), or equivalent, at the remote end. Attach MOVs between the leads and

ground. Failure to properly shield and protect leads c an result in equipment damage and/or unintentional operation.

FORM 4D CONTROL

Remote Terminal Unit (RTU)

Not All

Remote

Connections

Shown

Contact I/O

Module

J3

Recloser Trip and Lockout

Recloser Close

Ground Trip Block

Non-Reclose

Control Lockout Status

(Not Lockout)*

Recloser Open

(Recloser Not Open*)

Recloser Closed

(Recloser Not Closed)*

Control OK

(Control Not OK)*

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TB1

WET

+

WET —

Control-Supplied

Whetting Voltage

24 VDC/100 mA

(Resettable-Fuse

Protected)

Shield

Shield

Back Panel

Terminal

Block

TB2

CO4-NO

CI1

CI1

CI2

CI2

CI3

CI3

CI4

CI4

CO1-NO

CO1-COM

CO2-NO

CO2-COM

CO3-NO

CO3-NC

CO3-COM

CO4-NC

CO4-COM

* Relay contacts shown for indicated status. This is also the de-energized state.

Figure 20. Customer connections to Contact I/O Module 1 with shielding and surge protection. (I/O functionality

shown is factory-default configuration for Module 1. The configuration is modifiable via Configurable Logic tool in

ProView NXG software)

25OPERATION INSTRUCTIONS MN280049EN September 2017

Form 4D Microprocessor-based pole-mount recloser control installation and operation instructions

Loading...

Loading...