4.5 INCH CHIPPER

23

Section

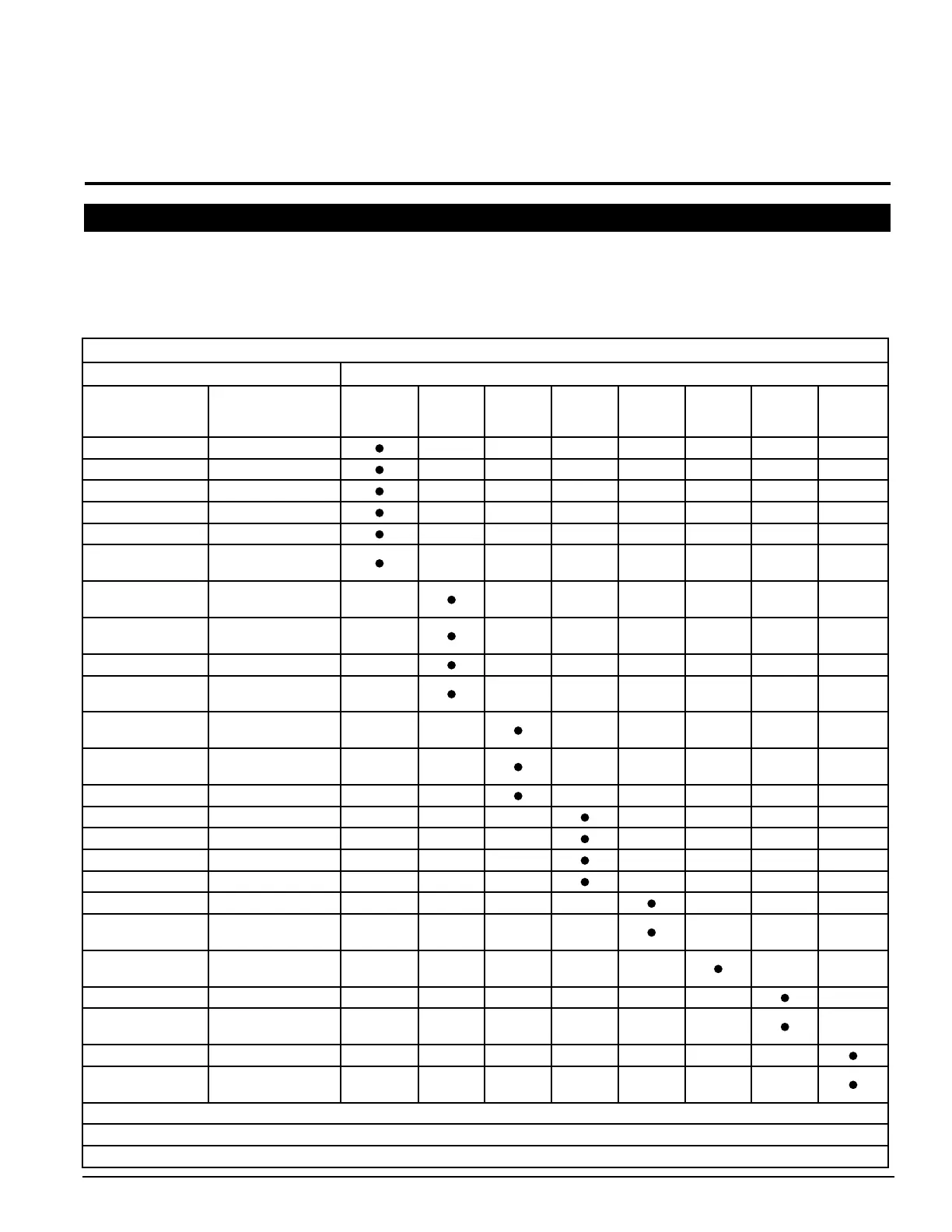

The items listed in the service and maintenance schedule are to be checked, and if necessary, corrective action taken.

This schedule is designed for units operating under normal conditions. If the unit is operating in adverse or severe usage

conditions it may be necessary for the items to be checked and serviced more frequently.

See engine owners manual for further maintenance and troubleshooting information.

SERVICE AND MAINTENANCE SCHEDULE

FREQUENCY

COMPONENT

MAINTENANCE

REQUIRED

BEFORE

EACH USE

EVERY

8

HRS

EVERY

25

HRS

EVERY

50

HRS

EVERY

100 HRS

EVERY

200 HRS

EVERY

500 HRS

EVERY

1500 HRS

ENGINE OIL CHECK OIL LEVEL

FUEL TANK FILL

AIR CLEANER CHECK & CLEAN

1

AIR INTAKE CLEAN

1

NUTS & BOLTS CHECK

CHIPPER BLADES

CHECK, SHARPEN

IF NEEDED

3

BELT TENSIONER

PIVOT

GREASE

PTO CROSS

JOURNALS

GREASE

PTO INNER TUBES GREASE

PTO SHIELD

BEARINGS

GREASE

PRE-CLEANER

ELEMENT

CLEAN

1

BELT/PULLEY

ALIGNMENT

CHECK

BELT CONDITION CHECK

TIRE PRESSURE CHECK

ENTIRE MACHINE CLEAN

ROTOR BEARING GREASE

SAFETY SWITCH CHECK

ENGINE OIL CHANGE

1

COOLING

SHROUDS

CLEAN

1

SPARK PLUG

CHECK CONDITION

AND GAP

STARTER DRIVE SERVICE

2

SOLENOID SHIFT

STARTER

DISASSEMBLE AND

CLEAN

2

FUEL FILTER REPLACE

BATTERY

CONNECTIONS

CHECK

1

Perform more frequently in dusty, dirty or severe usage conditions.

2

Have a Briggs or Honda engine service dealer perform this service.

3

It is a good sign that your chipper blades need sharpening when material stops self feeding.

4

SERVICE &

MAINTENANCE

4.1 MAINTENANCE SCHEDULE

Loading...

Loading...