CS-350WES

48

SAW CHAIN LUBRICATION SYSTEM

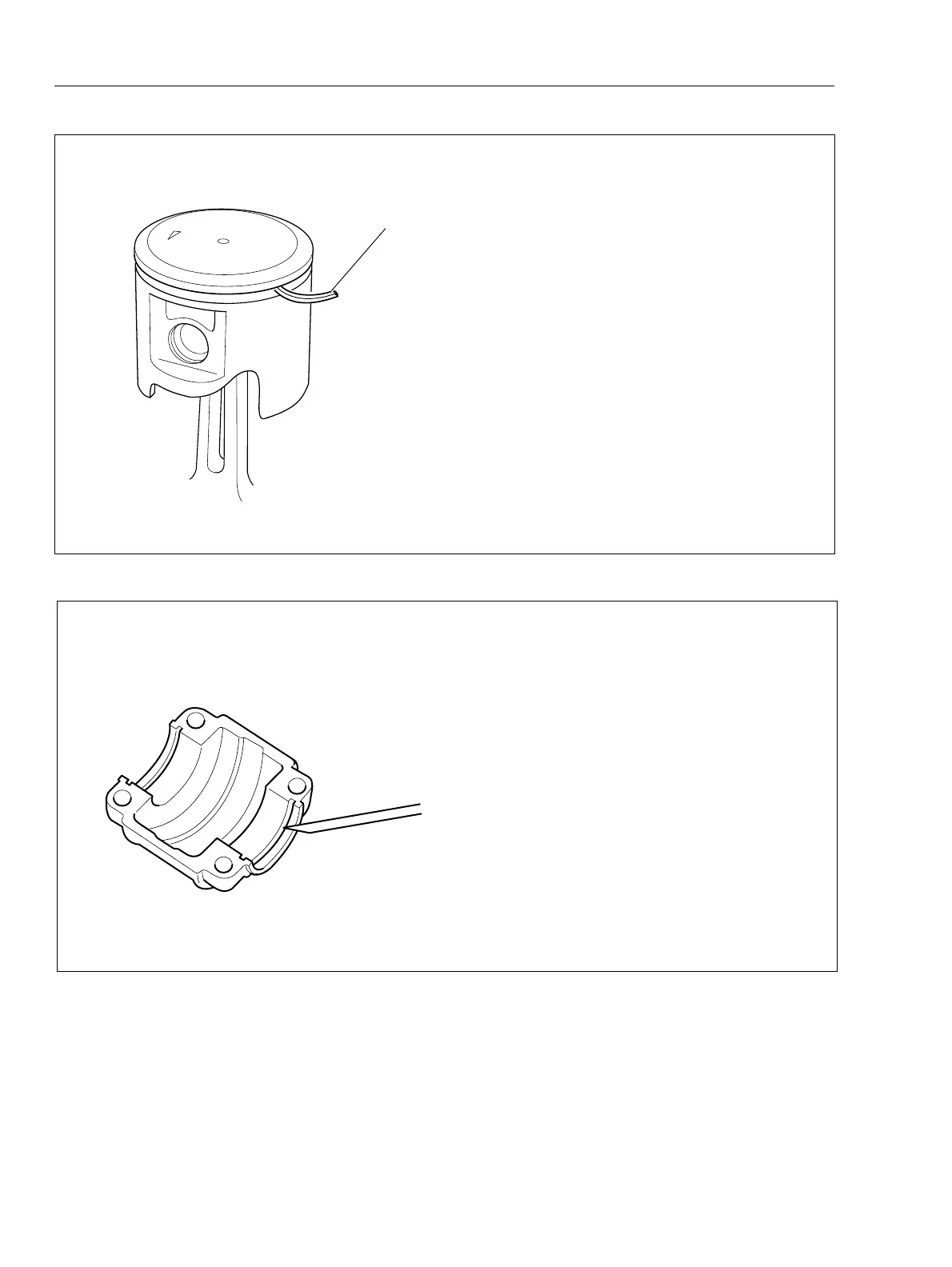

7-7 Checking piston and piston ring

1. Check piston ring and replace it if broken, scored,

or exceed service limits. Refer to 1-5.

2. Inspect piston crown and ring groove, and clean

with fine sand paper, oil stone, or ring groove

cleaning tool if carbon is deposited.

NOTE: The squared end of a broken piston ring (A)

can be used to clean the groove.

3. Remove snap rings from both sides of piston pin.

4. Push piston pin out from piston.

NOTE: If piston pin is tight, heat piston with a heating

gun, a heat lamp, or a suitable heater and/or use

piston pin tool 897702-30131 with adapter stamped

“8” on an end.

5. Inspect needle bearing and spacers, and replace

if wear or discoloration is noted.

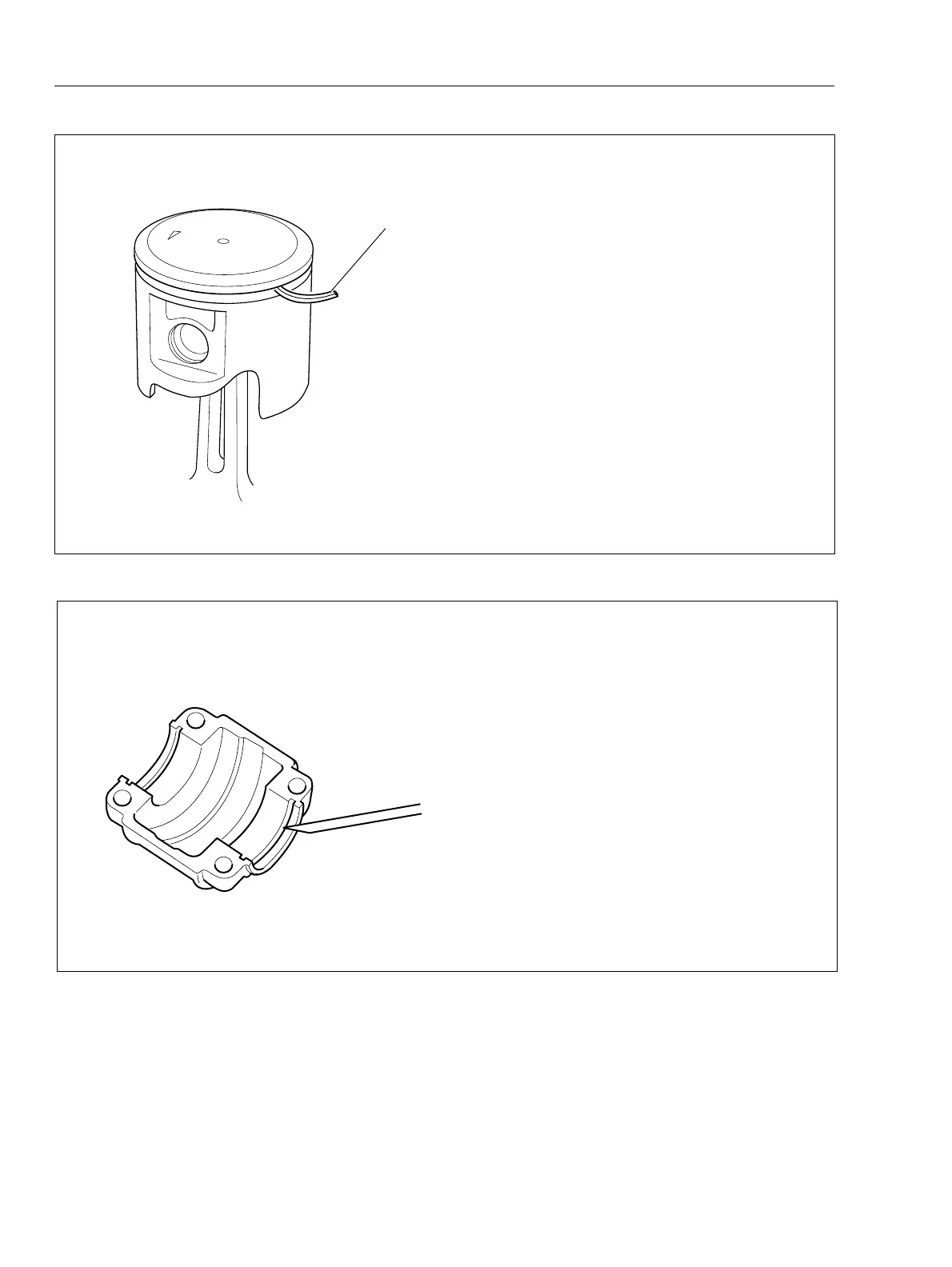

7-8 Checking crankcase and crankshaft

1. Clean lower crankcase. Replace as a set of upper

and lower crankcase if damaged.

2. Completely remove sealant residue on mating

surfaces and bearing bore of crankcase using

wooden or plastic scraper, or chemical gasket

remover.

3. Measure crankshaft runout and replace if it

exceeds service limits. Replace crankshaft if the

connecting rod bearing is rough, damaged, or

discolored.

1K264

(A)

Loading...

Loading...