CS-350WES

49

SAW CHAIN LUBRICATION SYSTEM

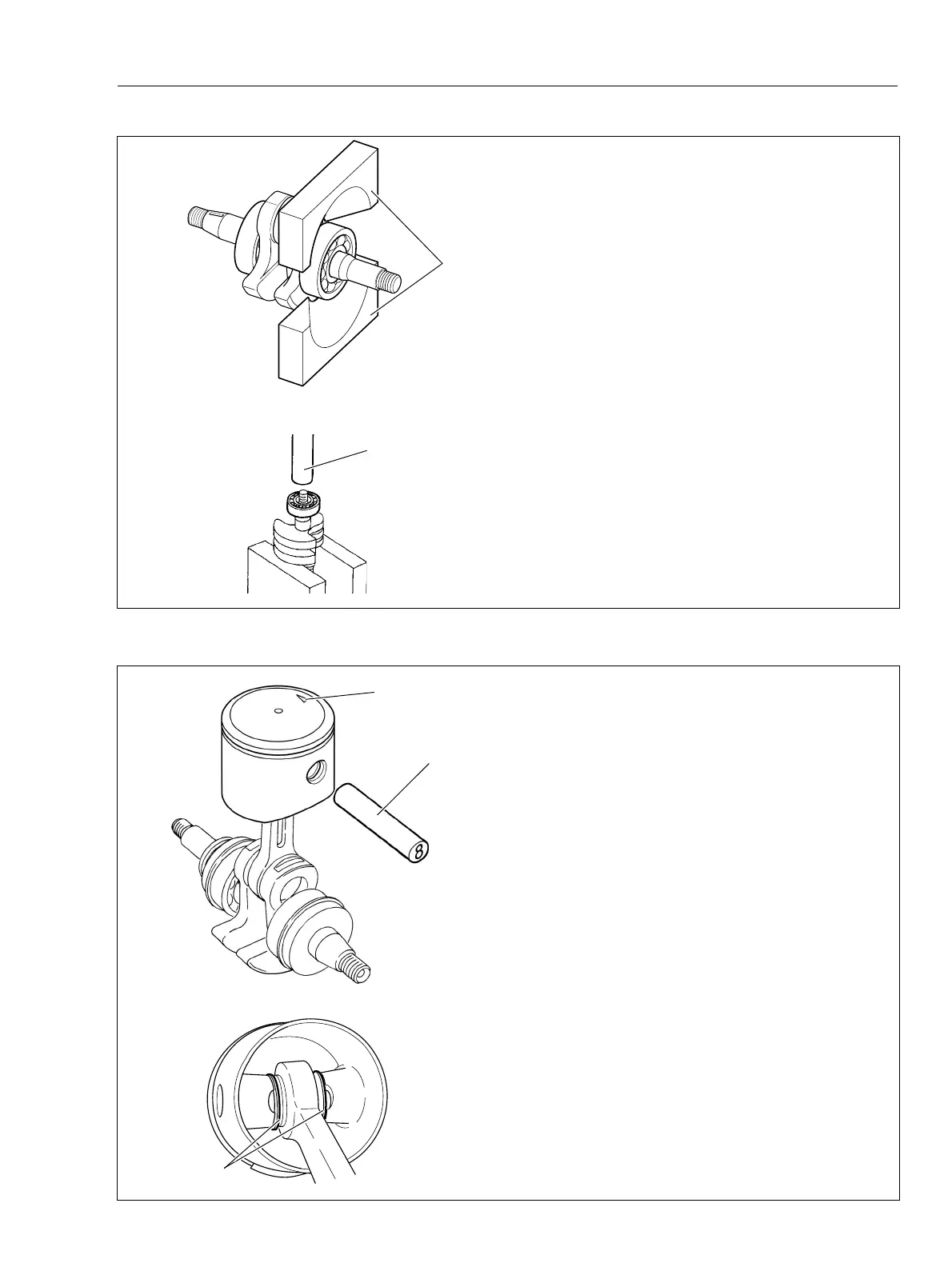

7-9 Replacing oil seal and ball bearing

1. Check oil seal(s) and replace if defective.

2. Check ball bearing(s) for smooth rotation. If not,

remove ball bearing(s) using bearing wedge (A)

897701-02830.

NOTE: When removing the oil seal or ball bearing

at clutch side, worm gear should be removed in

advance.

3. Install new ball bearing(s) using bearing/seal tool

897726-09130 (B) to the bottom.

NOTE: Preheat ball bearing using a heating gun,

heat lamp, or a suitable heater for easier installation.

4. Install oil seals into both ends of crankshaft with

taking care of proper direction of oil seal.

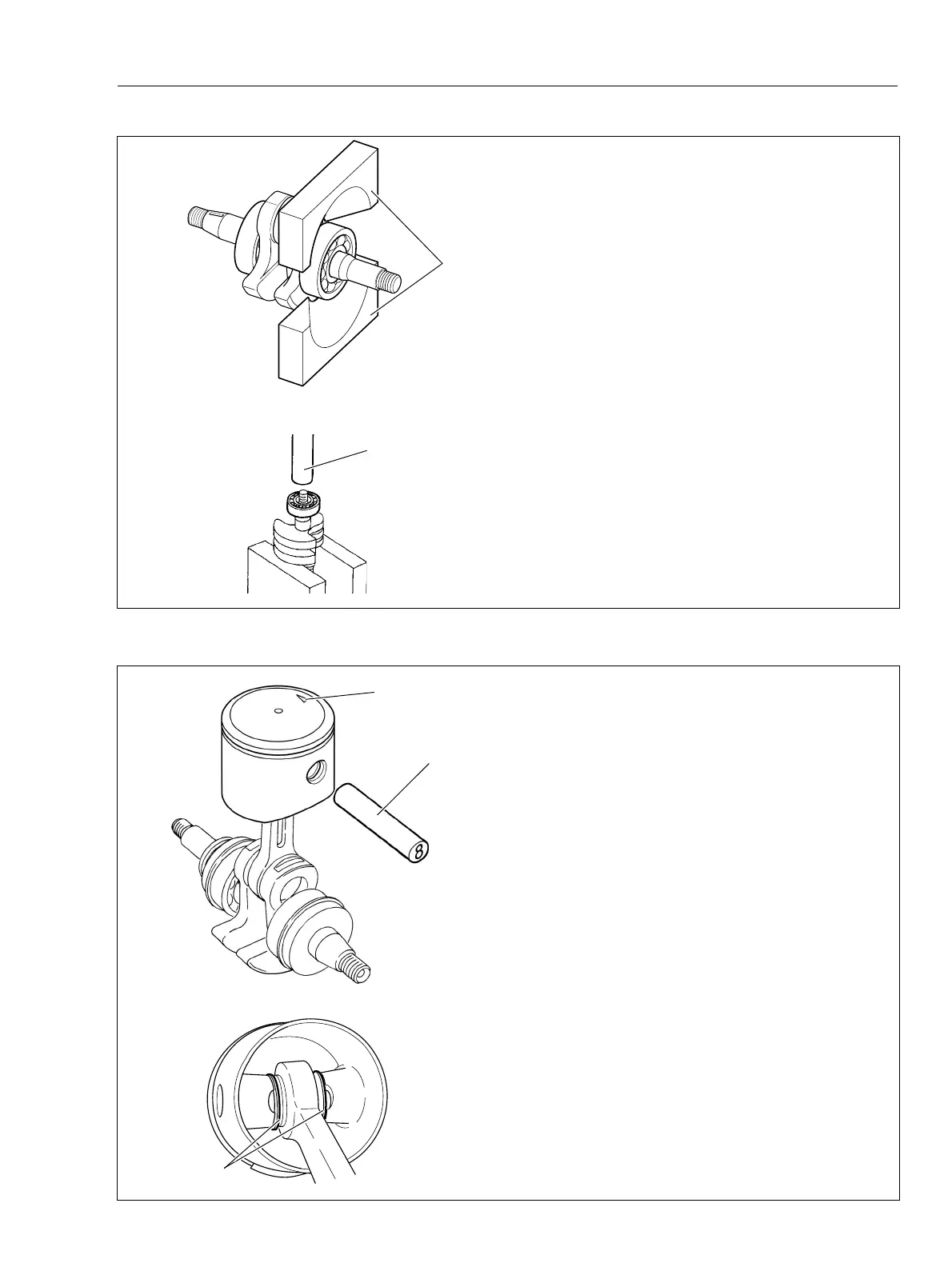

7-10 Installing piston and piston ring

1. Lubricate needle bearings with 2-stroke engine

oil.

2. Set needle bearing and piston pin spacers (C)

on small end of connecting rod. Place piston over

connecting rod with piston arrow mark (A) pointing

as shown.

3. Insert pin guide tool (B) stamped “8” through

piston, piston pin spacers and needle bearing in

small end of connecting rod.

4. Insert piston pin in piston pushing out the pin guide

until the pin end comes up to snap ring groove in

piston pin bore of piston.

NOTE: If piston pin is tight, use piston pin tool

897702-30131 with pusher stamped “8”.

5. Install new snap rings on both end of piston pin.

Make sure that they are properly seated in the

grooves.

NOTE: Always use new snap rings.

6. Install piston ring to piston.

1K327

(B)

(A)

(B)

(A)

(C)

Loading...

Loading...