www.seagullmodels.com

9

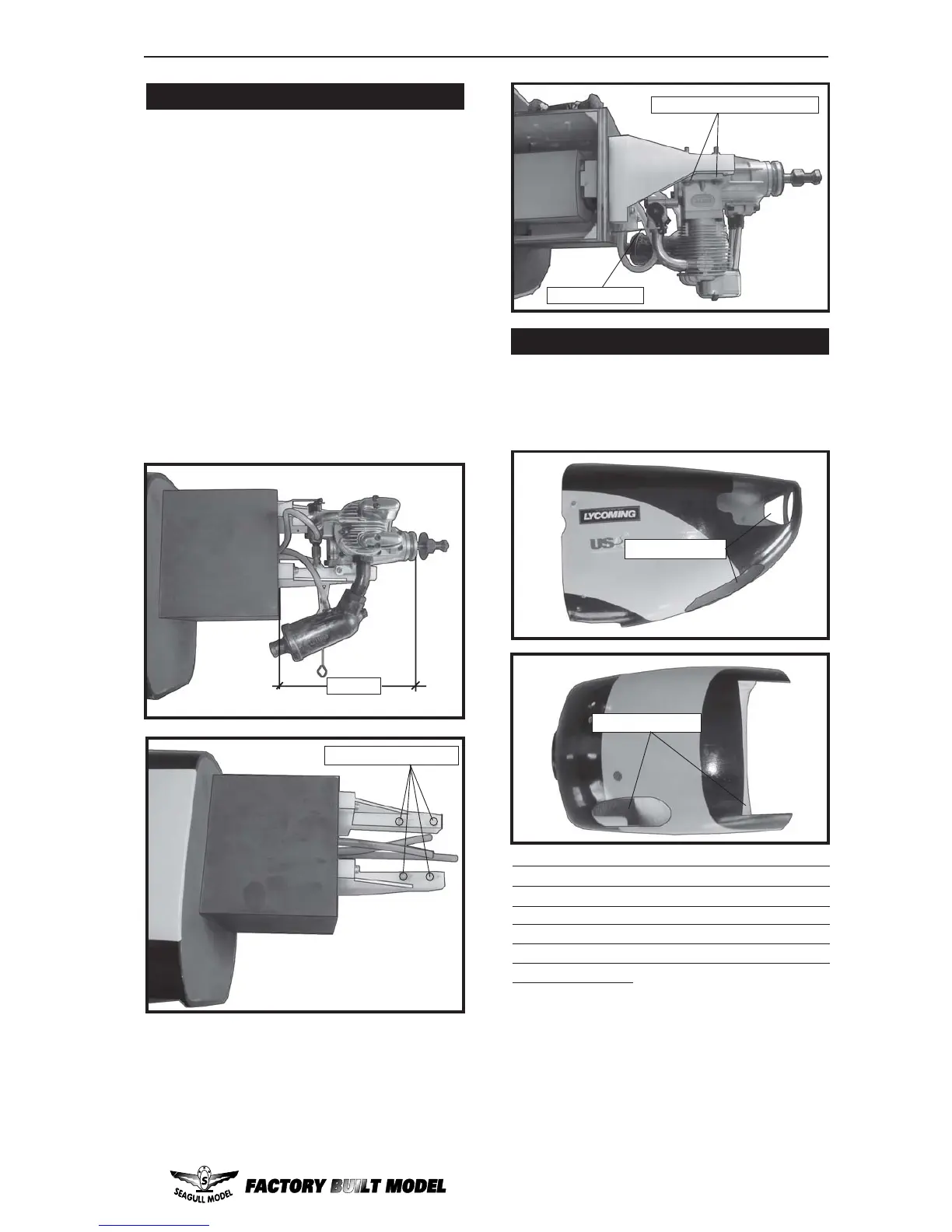

1) Install the pushrod housing through the

predrilled hole in the firewall and into the servo

compartment. The pushrod housing should

protrude 1/4" out past the front of the firewall.

Make a Z-Bend 1/4" from one end of the plain

wire pushrod.

MOUNTING THE ENGINE.

6) Attach the Z-Bend in the pushrod wire to

the throttle arm on the carburetor.

5) Bolt the engine to the engine mount using

the four machine screws. Double check that

all the screws are tight before proceeding.

4) Remove the engine. Using an drill bit,

drill the mounting holes through the engine

mount at the four locations marked.

2) Place your engine onto the engine

mount. Adjust the engine is centered of the

edges of the engine case.

3) When you are satisfied with the align-

ment, mark the locations of the engine

mounting.

155mm

.

4.2 mm diameter.

Machine Screw 4x30mm.

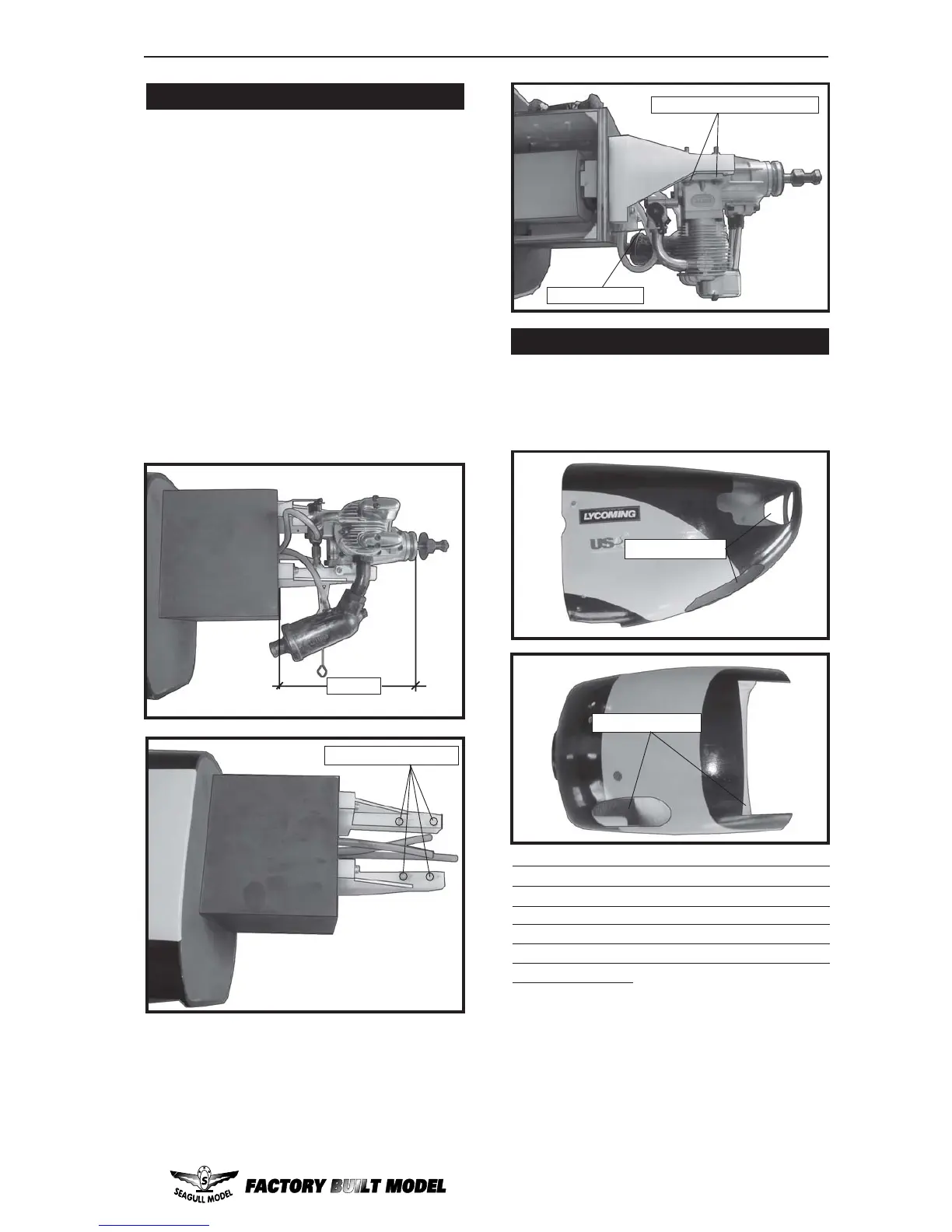

COWLING INSTALLATION.

1) Slide the fiberglass cowl over the en-

gine and line up the back edge of the cowl with

the marks you made on the fuselage then trim

and cut.

Pushrod wire.

Because of the size of the cowl, it may be nec-

essary to use a needle valve extension for the

high speed needle valve. Make this out of suf-

ficient length 1.5mm wire and install it into the

end of the needle valve. Secure the wire in

place by tightening the set screw in the side of

the needle valve.

Trim and cut.

Trim and cut.

2) While keeping the back edge of the

cowl flush with the marks, align the front of

the cowl with the crankshaft of the engine. The

front of the cowl should be positioned so the

crankshaft is in nearly the middle of the cowl

opening. Use the spinner backplate as a guide.

Hold the cowl firmly in place using pieces of

masking tape.

Loading...

Loading...