15

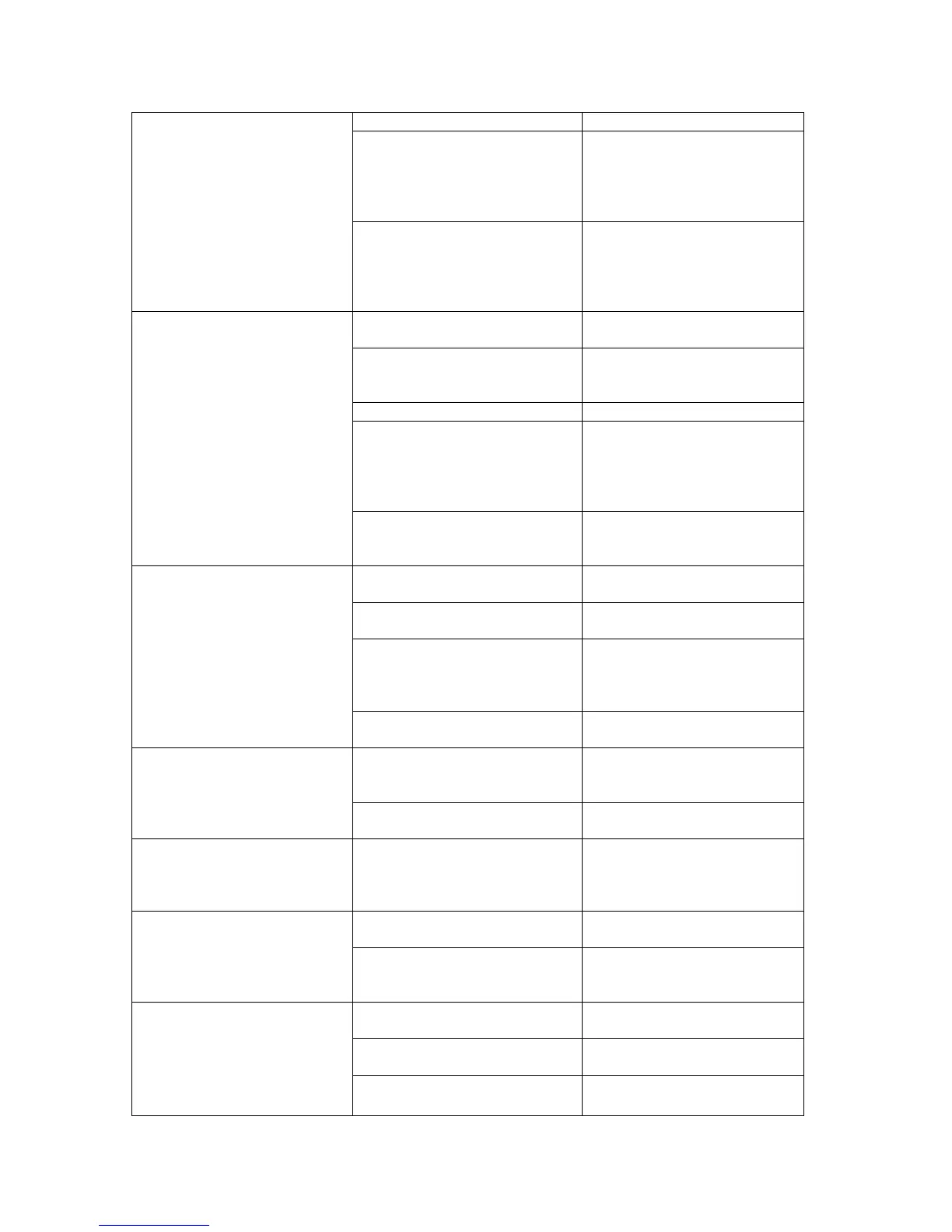

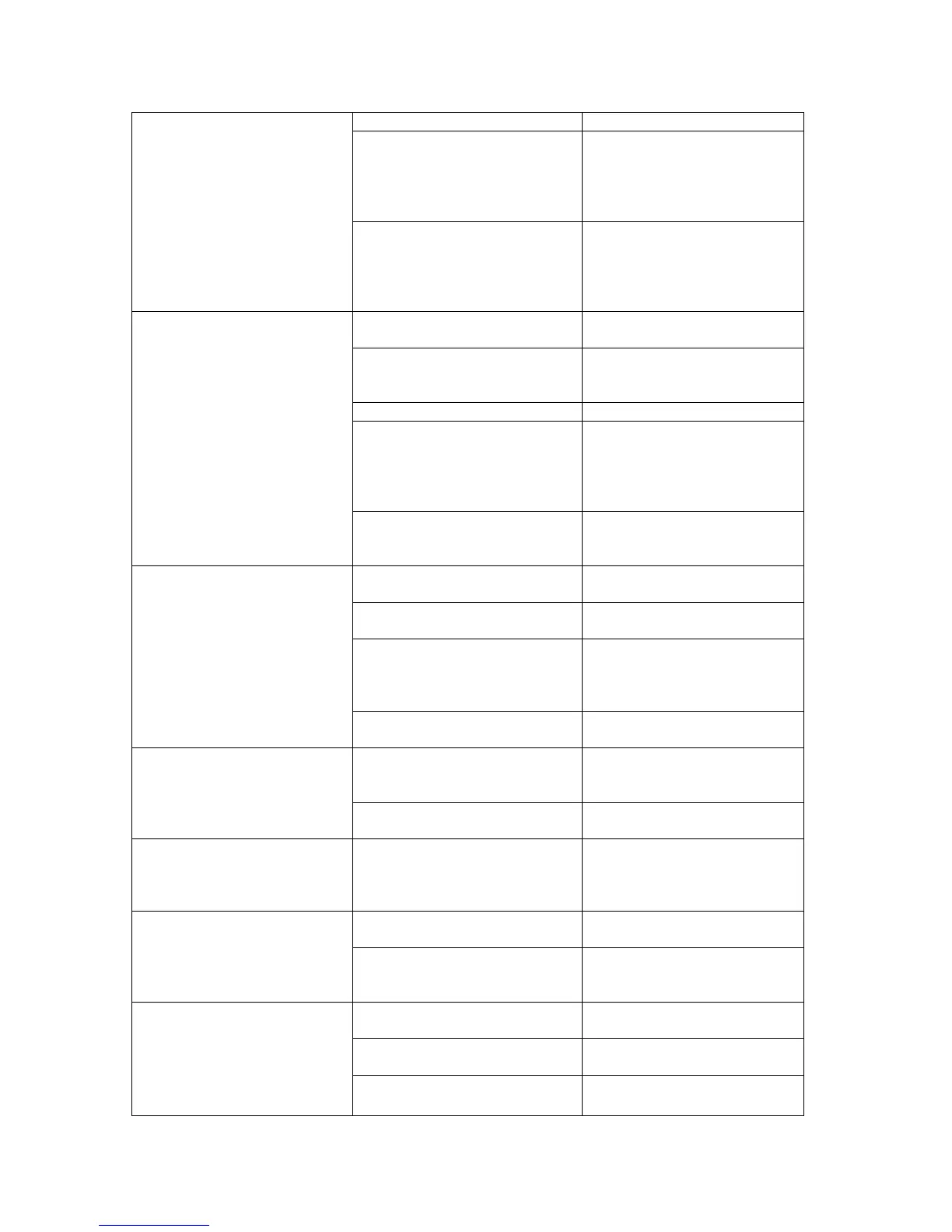

Glassware is not “Beer Clean”

Residue on glassware in the

form of oils will quickly

dissolve the formation of

foam (See “Beer Clean

Elongated dispensing hose.

temperatures and gauge

settings are calculated for a

dispensing hose five (5) feet

No beer flow from dispenser

2

2

2

off valve.

2

cylinder and regulator shut-

Line or dispenser obstructions.

‘kinks’ or obstructions in

either the air line or

dispenser line and that

Ensure all connections are

secure and all seals are in

place and in good condition.

Dispense system requires

cleaning.

See “Cleaning and

Maintenance”

Keg Coupler installed

incorrectly

Check seal between keg &

faucet

Line or dispenser obstructions.

obstructions in either the air

line or dispenser line and that

See “Using Proper Draw

Technique”

Handle not fully returned to

close position.

After every pour, ensure the

handle is returned to the off

See “Cleaning and

Maintenance”

2

Improper connection, air line

leak

Ensure proper connection of

air line at CO

2

regulator,

and/or check air line for

Difficulty Manipulating Faucet

handle

See “Cleaning and

Maintenance”

connector nuts and inspect

stem for possible damage.

Abnormal beer taste and/or

smell

Dispense system requires

cleaning.

See “Cleaning and

Maintenance”

Contaminated dispense

system.

Check hoses for possible air

leaks.

The beer exceeded self-life.

Loading...

Loading...