IDENTIFYING THE TYPE OF LOW-E:

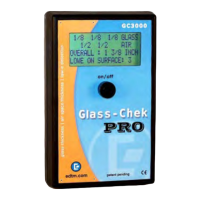

In addition to identifying the location of Low-E coatings, the GC3000 determines the

type of Low-E on your glass application. The meter will specify it as “hard coat” or “soft

coat.” If soft coat, the meter will also specify the number of silver-layers as single,

double, or triple, based on the coating’s energy performance. If you happen to know

the manufacturer of the glass, in many cases you can identify the exact type of Low-E

coating used to make the window. Here are some examples:

GLASS THICKNESS RANGE

• Minimum Glass Thickness Allowed: 0.080 inch or 2.0mm

• Minimum Air Space Allowed: 0.187 inch or 4.7mm

• Glass Thickness Allowed for Low-E Readings: up to 0.5 inch or 12.7mm

Triple Pane Windows

The GC3000 will display the thickness of each pane of glass,

the thickness of each air space, and the total IG thickness. De-

pending on the thickness of the glass, the maximum allowable

range for the total IG thickness changes according to the data

below:

Double Pane Windows (including win-

dows with suspended lm)

The GC3000 will display the thickness of

each pane of glass, the thickness of each

air space, and the total IG thickness. De-

pending on the thickness of the glass, the

maximum thickness range for the total IG

thickness changes according to the data

below. **Note** these same dimensions

apply when measuring a double pane

window with suspended lm.

Single Pane Glass

The GC3000 will display the thickness of single panes of glass

up to 2.75 inches or 70mm thick.

Laminated Glass

The GC3000 will measure the overall thickness as long as

there is no Low-E coating against the laminate inner-layer. The

laminate assembly can be a single piece or combined into an

insulating unit. The GC3000 will NOT measure the PVB inner-

layer or the individual pieces of glass making up the laminated

glass; it will simply give the overall thickness of the laminated

piece.

WARRANTY

The manufacturer warrants all models of the GC3000 to be free from defects in material and workmanship

under normal use and service as specied within the operator’s manual. The manufacturer shall repair or

replace the unit within twelve (12) months from the original date of shipment after the unit is returned to the

manufacturer’s factory, prepaid by the user, and the unit is disclosed to the manufacturer’s satisfaction, to be

thus defective. This warranty shall not apply to any unit that has been repaired or altered other than by the

manufacturer. The aforementioned provisions do not extend the original warranty period of the unit which has

been repaired or replaced by the manufacturer. Batteries are not covered by warranty.

The manufacturer assumes no liability for the consequential damages of any kind through the use or misuse

of the GC3000 product by the purchaser or others. No other obligations or liabilities are expressed or implied.

All damage or liability claims will be limited to an amount equal to the sale price of the GC3000, as established

by the manufacturer.

SOFT COAT (sputtered)

HARD COAT (pyrolytic)

Triple Silver

- Cardinal 366

- PPG SolarBan 70

- Guardian ClimaGuard 62/27

Double Silver

- Cardinal 270 & 272

- PPG SolarBan 60

- AFG TIPS, TIR, & TIAC

- Guardian ClimaGuard 71/38

Single Silver

- Cardinal 179

- PPG Sungate 100

- Guardian ClimaGuard 75/68

- Pilkington Energy Advantage

- PPG Sungate 500

- AFG Comfort E2

Maximum Overall Thickness Range

1.9” or 48 mm

2.0” or 50 mm

2.1” or 53 mm

2.5” or 63 mm

Glass Thickness

3/32” or 2.5 mm

5/32” or 4 mm

1/4” or 6 mm

1/2” or 12 mm

Glass Thickness

3/32” or 2.5 mm

1/4” or 6 mm

1/2” or 12 mm

Maximum Overall Thickness Range

1.9” or 48 mm

2.0” or 50 mm

2.2” or 55 mm

PVB WITH LOW-E MODE (LAMINATED GLASS WITH LOW-E)

When working with laminated glass that has a Low-E coat-

ing placed against the PVB inner-layer, the Glass-Chek

PRO is capable of helping you identify which surface has

the Low-E coating. To perform this function, the meter must

be switched into “PVB WITH LOW-E” mode (see page 1).

When testing laminated glass with Low-E, the meter will test

laminated pieces of glass alone, and it will also test lami-

nated

Low-E glass that has been built into a double pane

window assembly. For double pane window assemblies,

the GC3000 meter must be placed against the side of the

window that contains the laminated Low-E piece of glass.

The rst screen that appears will show the thickness of the

overall laminated piece of glass, the air space, the second

pane of glass thickness, and also the overall thickness of

the double pane window assembly. The second screen will

show the make-up of the laminated Low-E piece of glass.

The meter has been designed to add the thickness of the

PVB layer to the thickness of the glass that contains no Low-

E coating. For the piece of glass coated with Low-E, the

meter will display the actual thickness of the glass itself.

This means that the piece of glass that has an abnor-

mal (larger) glass thickness (caused by adding the

PVB layer thickness to the glass thickness) will be the

pane that is clear of any Low-E coating.

The piece of glass that is displayed as a “normal”

thickness (0.124” for example) is the pane that has the

Low-E coating on it.

The display examples below correspond with how the meter would read the example

at right. Screen 1 displays the thickness of the entire window. The “PANE 1” result on

the rst screen refers to the thickness of the laminated Low-E glass assembly. Screen

2 displays the details of the laminated Low-E glass assembly only. Screen 3 conrms

the presence of a Low-E coating and displays the type of Low-E.

The “normal” thickness of .124” (Screen 2 / Line 3) indicates the Low-E coating is on

the 2nd pane (surface 3) of the laminated portion of the window.

1) 2) 3)

Pane 1 (0.124”) + PVB Layer (0.035”) = 0.159” on near side of coating (Screen 2 Line 1)

Pane 1 (0.124”) + PVB Layer (0.035”) + Pane 2 (0.124”) = 0.283” total laminated glass thick-

ness (Screen 1 Line 1 and Screen 2 Line 4)

Air Space Thickness (.500”) (Screen 1 Line 2)

Total Window Thickness (0.907”) (Screen 1 Line 4)

SPECIFICATIONS

POWER SOURCE 9 volt alkaline battery (NEDA 1604A) only

PHYSICAL DIMENSIONS 3.5” x 5.5” x 1.7 inch (89 x 140 x 43mm)

WEIGHT 0.75 pounds

MAXIMUM LASER OUTPUT <1mW (2M laser product)

LASER WAVELENGTH 650 - 680 nm

STORAGE TEMPERATURE -10 to +60 degrees Celsius

OPERATING TEMPERATURE 0 to +40 degrees Celsius

DISPLAY 4 lines X 20 characters

ACCURACY:

-High Resolution Mode -Low Resolution Mode (Default)

Pane 1 0.004 inch (0.1mm) Pane 1 0.008 inch (0.2mm)

Air Space 0.012 inch (0.3mm) Air Space 0.012 inch (0.3mm)

Pane 2 0.006 inch (0.15mm) Pane 2 0.012 inch (0.3mm)

This product complies with IEC 60825-1 and FDA regulation 21 CFR 1040.10.

The thickness tolerance is calibrated to NIST traceable standard No. 821/268634-03.

AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) -- Tolerance specications for at glass

When operating the GC300 in “STANDARD” mode, the measurements will be rounded to the nearest standard ac-

cording to the table below:

DESIGNATION TOLERANCE

mm

2.5

3

4

5

6

8

10

12

inches

0.09

0.12

0.16

0.19

0.23

0.32

0.39

0.50

mm max.

2.57

3.40

4.19

5.05

6.20

8.43

10.31

13.49

mm min.

2.16

2.92

3.78

4.57

5.56

7.42

9.02

11.91

inches min.

0.085

0.115

0.149

0.180

0.219

0.292

0.355

0.469

inches max.

0.101

0.134

0.165

0.199

0.244

0.332

0.406

0.531

TRADITIONAL

DESIGNATION

3/32 in. (single)

1/8 in. (double)

5/32 in.

3/16 in.

1/4 in.

5/16 in.

3/8 in.

1/2 in.

PANE 1

AIR SPACE

PANE 2

AIR SPACE

PANE 3

SINGLE LITE GLASS

GLASS

GLASS

PANE 1

AIR SPACE

PANE 2

Suspended Film

(

PANE 1

AIR SPACE

AIR SPACE

PANE 2

Suspended Film

(

LAMINATED PANE 1 (0.124”)

LAMINATED PANE 2 (0.124”)

WINDOW PANE 2 (0.124”)

AIR SPACE (0.5”)

Glass

Surface # 1 2 3 4 5 6

PVB Layer

(0.35”)

(

Low-E

(

Whole Window

Laminated

Glass

4

Loading...

Loading...