A726-01-880 Issue M

Page 26 © Edwards Limited 2010. All rights reserved.

Edwards and Edwards logo are trademarks of Edwards Limited.

Maintenance

5.3 Inspect and clean the inlet strainer

Whenever you disconnect the pump from your vacuum system, we recommend that you:

Remove any debris trapped by the inlet strainer (in the inlet port).

Inspect the inlet strainer and if necessary, clean it with a cleaning solution suitable for the substances

pumped. Refit the inlet strainer before you reconnect the pump to your vacuum system.

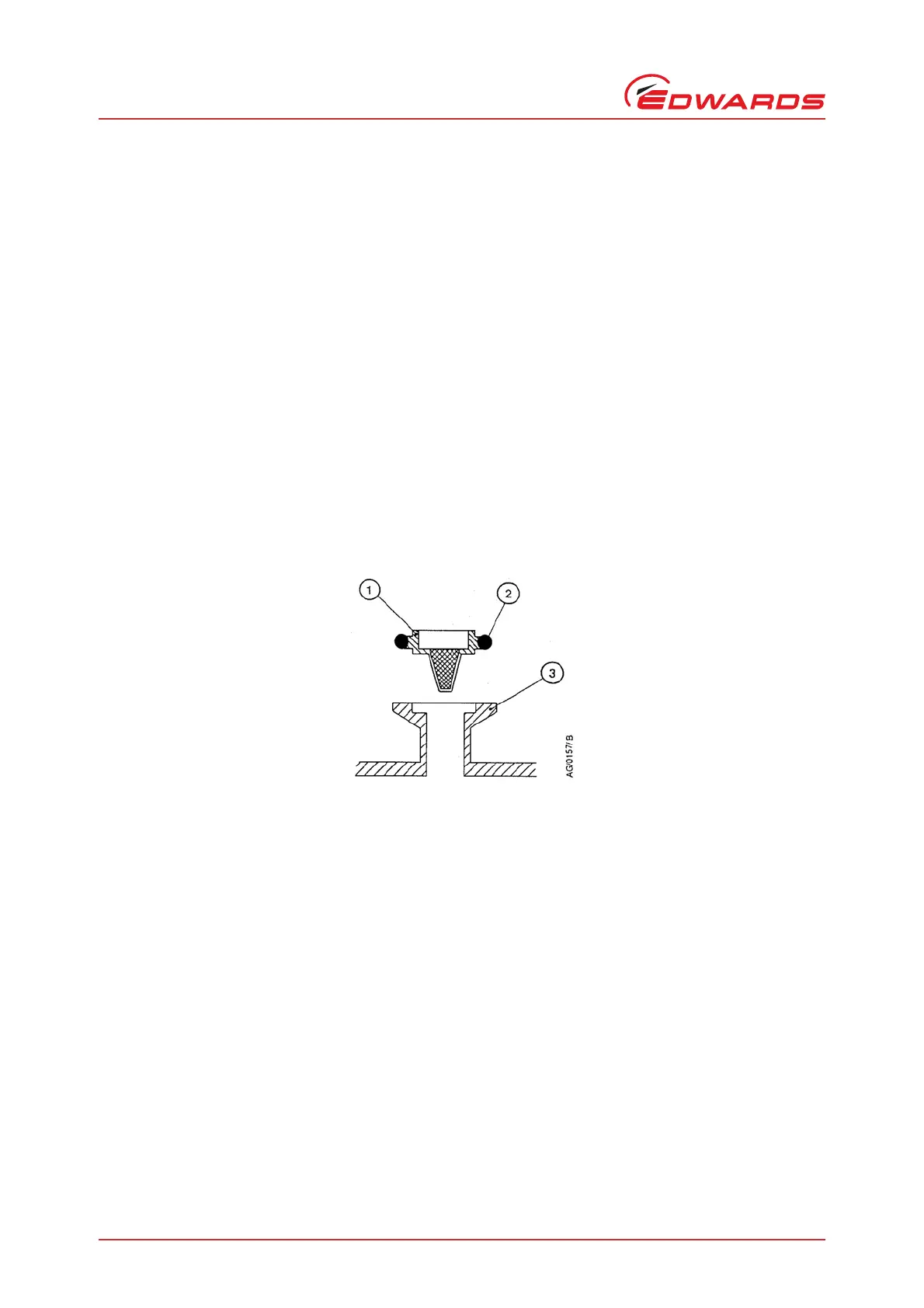

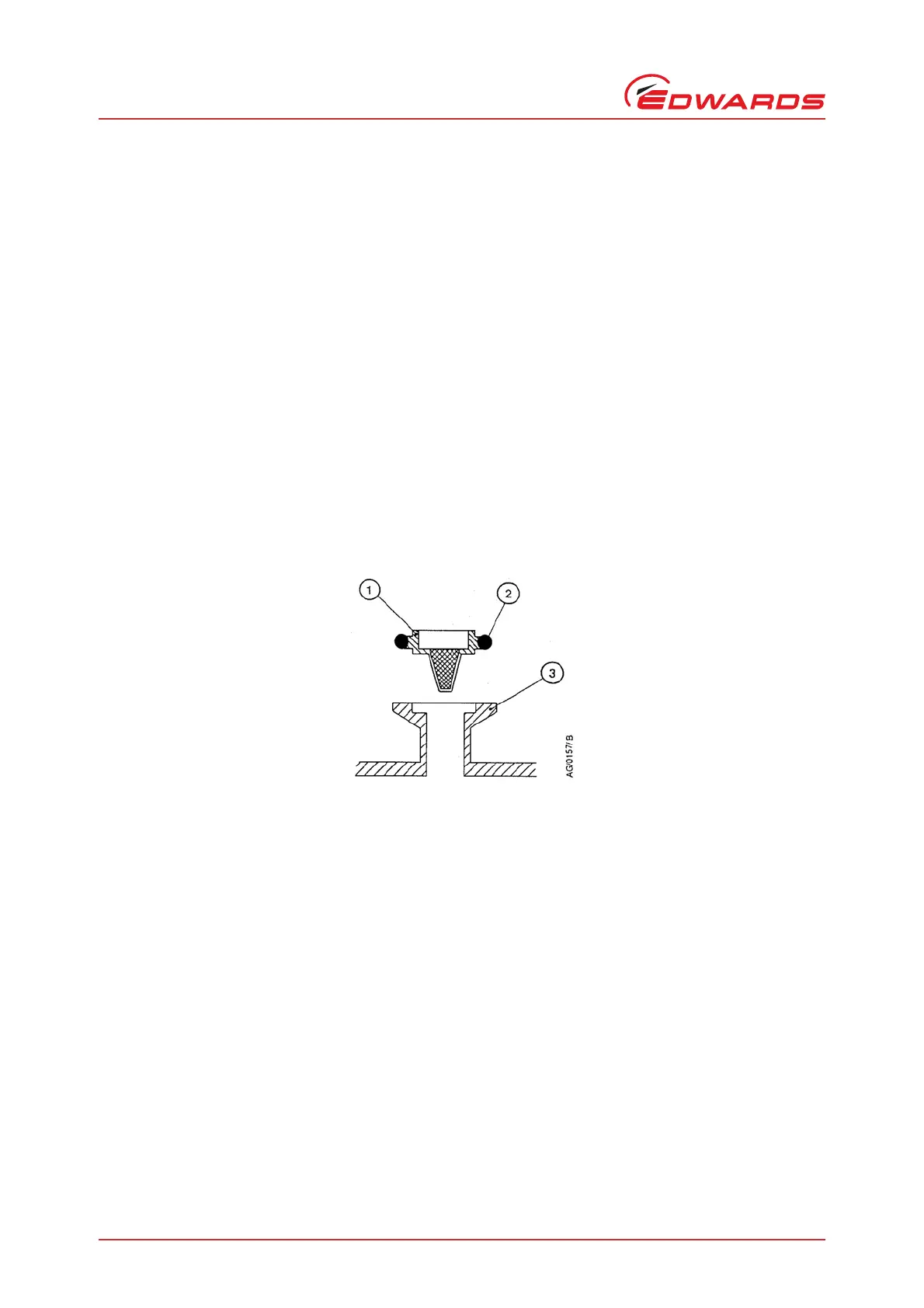

1. Refer to Figure 8. Disconnect your vacuum system from the pump inlet-port (3) and remove the centring-ring

and strainer assembly (1) and the O-ring (2). Inspect the centring-ring and the O-ring. If they are clean, continue

at Step 5. If they are not clean, continue at Step 2.

2. Remove the O-ring (2) from the centring-ring and strainer assembly (1). Do not allow the O-ring to come into

contact with the cleaning solution.

3. Wash the centring-ring and strainer assembly in a suitable cleaning solution and allow it to dry.

4. If necessary, wipe the O-ring with a clean, dry, lint-free cloth.

5. Refit the centring-ring and strainer assembly and the O-ring to the inlet-port. Refit your vacuum system to the

pump inlet-port.

Figure 8 - Inlet strainer assembly

5.4 Inspect and clean the gas-ballast control (if fitted)

The gas-ballast filter element is retained in its seating with adhesive; do not try to remove it.

1. Refer to Figure 9. Turn the gas ballast control to the high flow position (II).

2. Push the control down against the compression spring as far as it will go, then turn the control anti-clockwise

slightly to release the bayonet lugs and remove the control.

3. If necessary, wipe the control with a clean, dry, lint-free cloth and ensure that the air-hole is not blocked.

4. Refit the control into the gas-ballast inlet and ensure that the compression spring locates correctly between the

bayonet lugs.

5. Push the control down as far as it will go and then turn the control clockwise slightly until the bayonet lugs

engage correctly.

6. Reset the gas-ballast control to the required position.

1. Centering ring and strainer

2. O-ring

3. Pump inlet-port

Loading...

Loading...