ef cooling Ernst H. Furrer AG Operating manual

7-24 Chapter page Issue: 07 / 2015 Cooling unit EVO 45, 0390.013

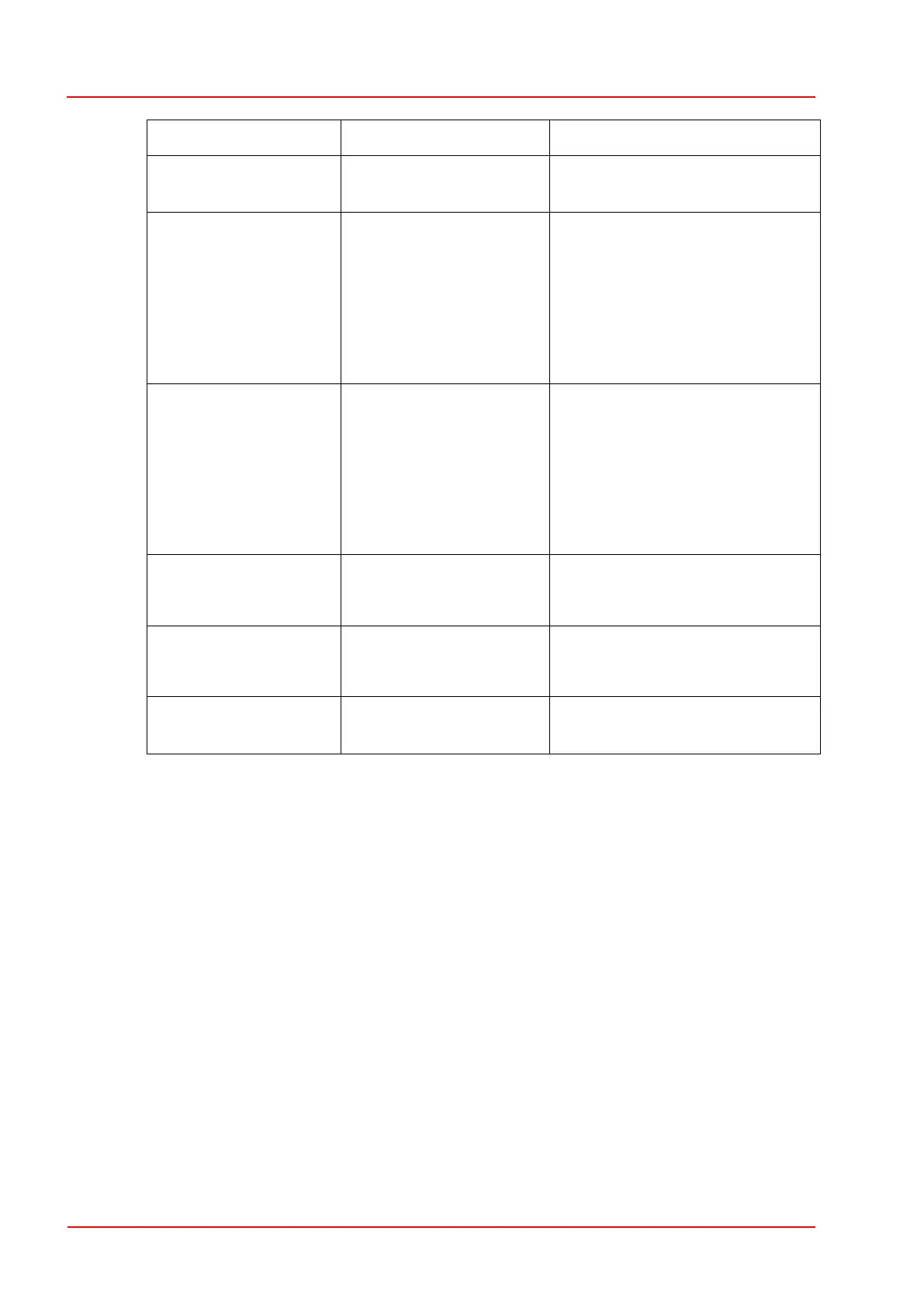

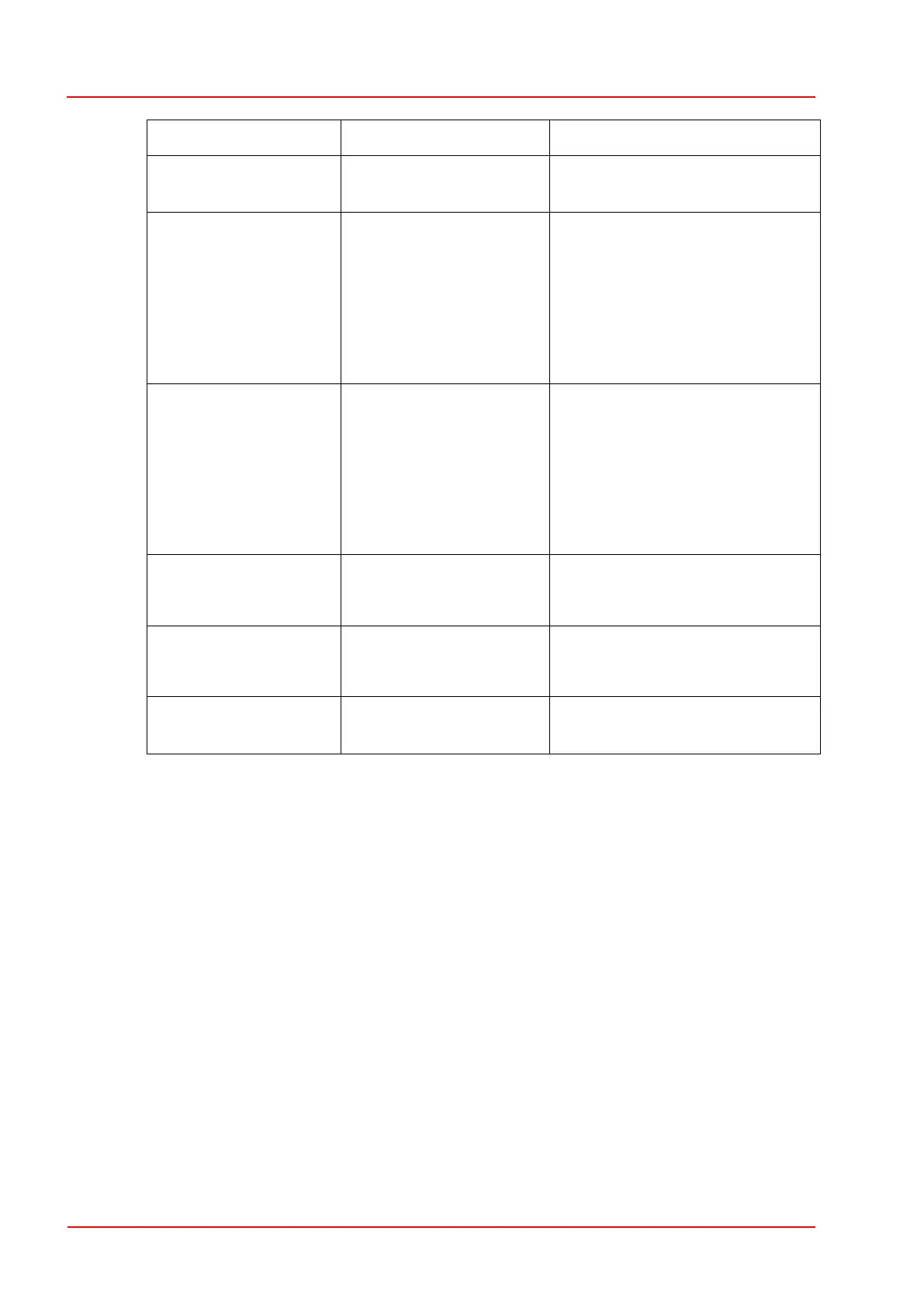

Alarm Possible causes Remedy

LOW PRESSURE

– Refrigerant loss Leakage

– Expansion valve (thermal part /

– Request Customer Service

HIGH PRESSURE

– Air filter mats fouled

– Condenser fouled

– Air supply or removal obstructed

– Air inlet temperature > 45°C

– Intake air and waste air “short

circuited”

– Water-cooled units: Water

supply or recooling system

defective

– Clean/replace filter mats

– Clean condenser

– Remove obstructions

– Thoroughly ventilate the area with

additional fans

– Change the set-up location

– Request Customer Service

– Water-cooled units: Check water supply

or recooling system

– Request Customer Service

HIGH PRESSURE SAFETY

– Air filter mats fouled

– Condenser fouled

– Air supply or removal

obstructed

– Air inlet temperature > 45°C

– Intake air and waste air “short

circuited”

– Water-cooled units: Water

supply or recooling system

– Clean/replace filter mats

– Clean condenser

– Remove obstructions

– Thoroughly ventilate the area with

additional fans

– Change the set-up location

– If necessary, request Customer Service

– Water-cooled units: Check water supply or

recooling system

– Request Customer Service

FLOW IN MEDIUM CIRCUIT

INSUFFICIENT

– No water flow or insufficient

water flow

– Flow meter or pump defective

– Clean/replace water filter

– Check hoses for kinks

– Request Customer Service

PROTECTION AGAINST

FREEZING

– Insufficient water flow (if

compressor is in operation)

– Ambient temperature too low

– Pumps should be operating at temperatures

below 8°C

– Heating should be operating at below 4 °C

– Request Customer Service

WATER LEVEL INSUFFICIENT

– Leakage

– Check the pipes for leaks

– Request Customer Service

If the malfunction cannot be remedied with the aid of this malfunction table or the alarm

no. is not contained in this list, please contact the internally responsible maintenance

specialist or contact our Customer Service:

support@efcooling.com.

Please provide us with the type and serial number of the unit as well as all alarm

numbers that occurred (scroll to the alarm message with the arrow key).

A complete list of the fault messages can be found in Chap. 13.7 PLC manual Troubleshooting

requires qualified personnel. Please contact our Support should there be any questions.

Loading...

Loading...