BASIC MAINTENANCE PROCEDURESBASIC MAINTENANCE PROCEDURES

e rear suspension of your motorcycle has 2 dierent adjustment points. It can be adjusted for the rider’s weight

and riding conditions by changing the spring pre-load, rebound and compression damping points. It comes from

the factory set to the soest setting. If you wish to make the rear suspension harder, follow the procedures below.

Adjusting the rear shock is not hard, but like the front forks, changes should be made one at a time to gain an

accurate understanding of how they aect the bike.

Once you are familiar with the settings on your suspension, you can quickly and easily adjust them to suit dier-

ent terrain. For example, you know the setting position for when you ride in the sand dunes. But when you are

riding on your local track you know to tune them to a dierent setting.

e rear shock absorber has a damper unit that containers high pressure nitrogen gas. Do not attempt to disas-

semble, service or dispose of it. Puncture or exposure to ame may also result in an explosion, causing serious

injury or even death. Service or disposal should only be done by your dealer or a qualied mechanic that is

equipped with the proper tools and safety equipment.

If your EGL MotorEGL Motor motorcycle is new, put about 2 hours of part throttle break in time on it to ensure that the

shock absorber has worked in.

CHECKING BRAKE PADSCHECKING BRAKE PADS

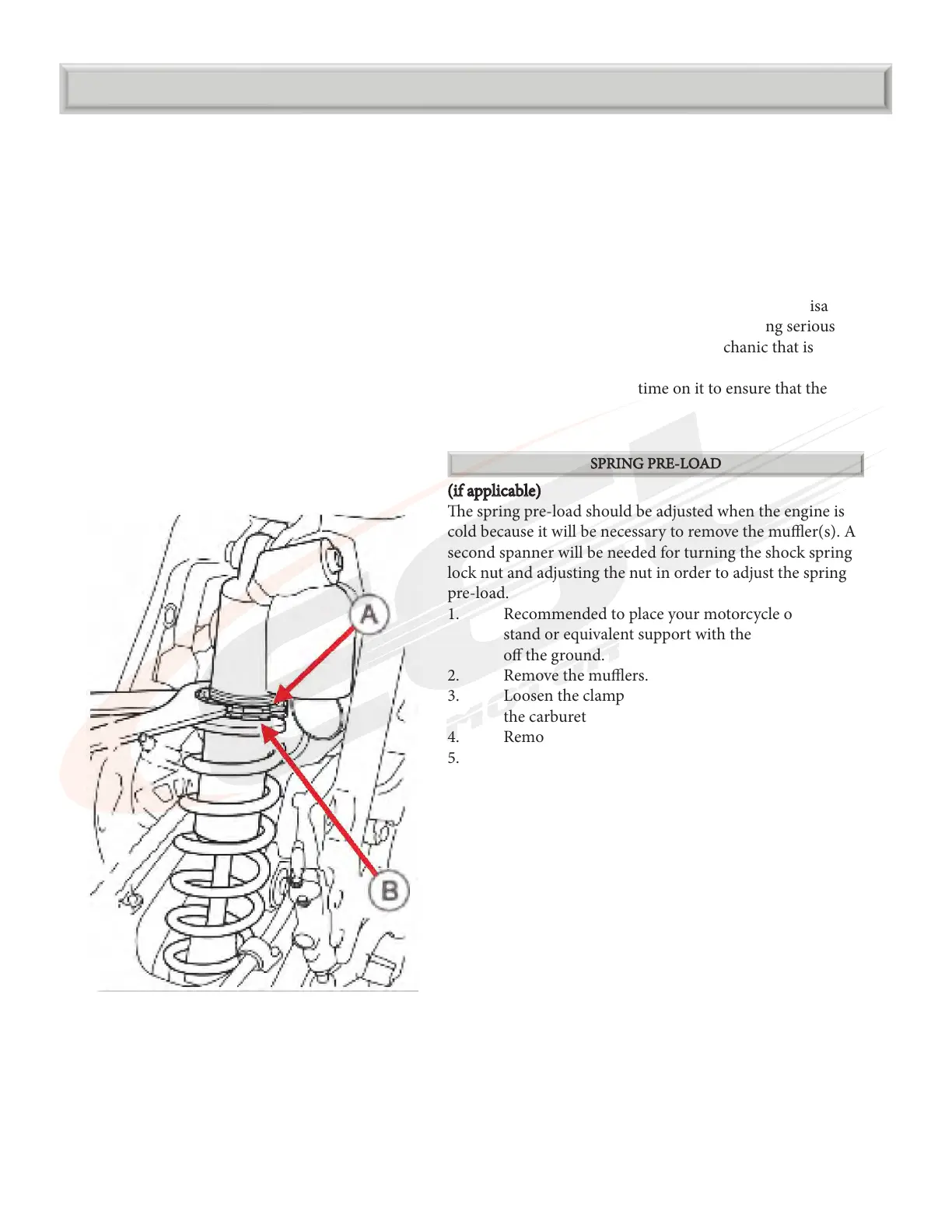

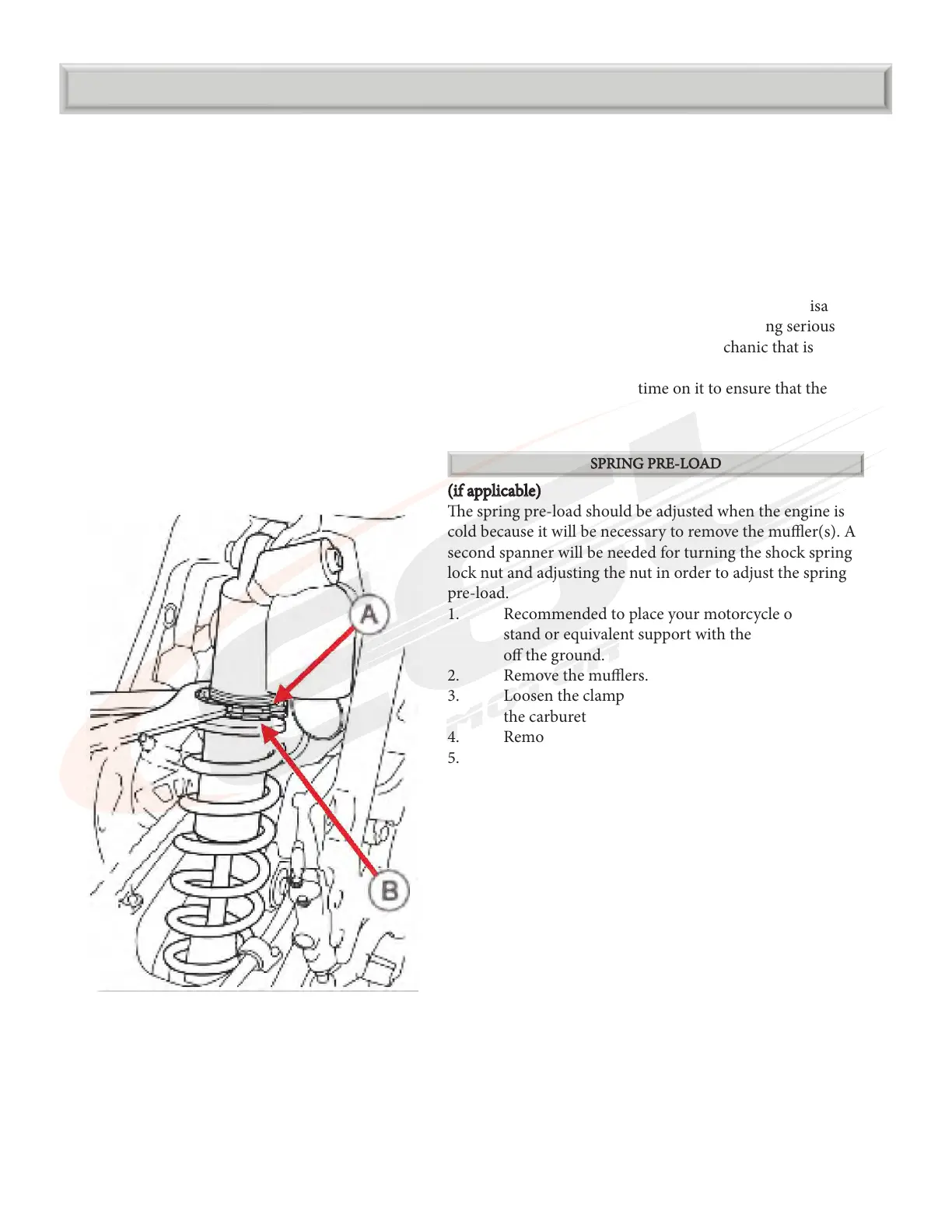

SPRING PRE-LOAD SPRING PRE-LOAD

(if applicable)(if applicable)

e spring pre-load should be adjusted when the engine is

cold because it will be necessary to remove the muer(s). A

second spanner will be needed for turning the shock spring

lock nut and adjusting the nut in order to adjust the spring

pre-load.

1. Recommended to place your motorcycle on a

stand or equivalent support with the rear wheel

o the ground.

2. Remove the muers.

3. Loosen the clamp on the air lter duct connecting

the carburetor.

4. Remove the battery terminal connectors.

5. Remove the sub-frame with the air lter housing on

one piece.

6. Check that the spring pre-load is adjusted to the

standard length.

7. Adjust as necessary by loosening the shock

spring lock nut (A)(A) and turning the adjusting nut

(B)(B)

8. One complete turn of the adjuster nut changes the

spring length by approximately 1.5 -2 mm.

9. Aer the adjustment has been done, hold the

adjuster nut and tighten the spring lock nut.

10. Make sure the lock nut is tight before you assemble

the remaining parts.

Loading...

Loading...