19

20

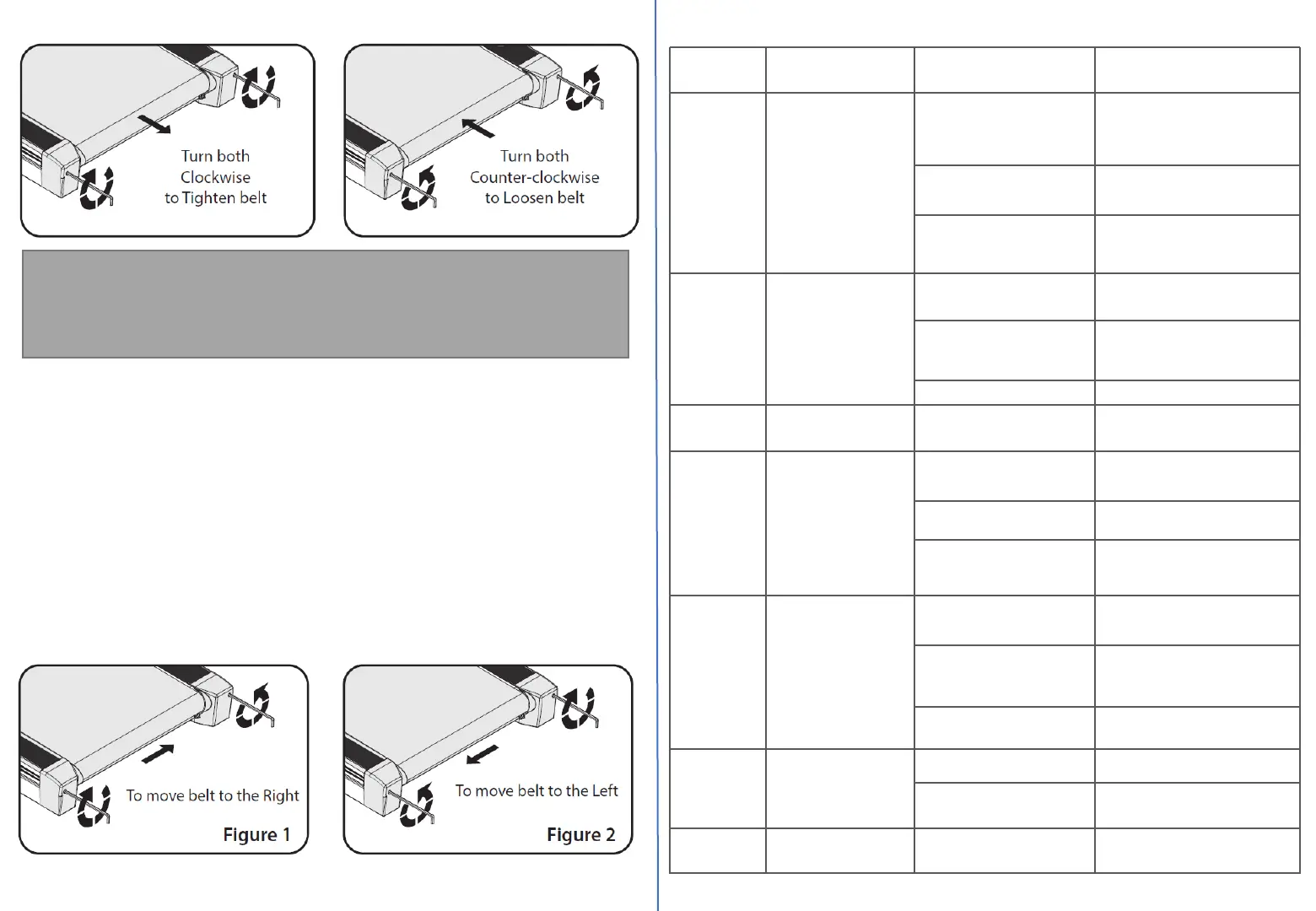

CAUTION: DO NOT tighten more than 2 full turns on each side. Over

tensioning the belt can cause unnecessary friction and wear and tear

on the belt, motor and electronics.

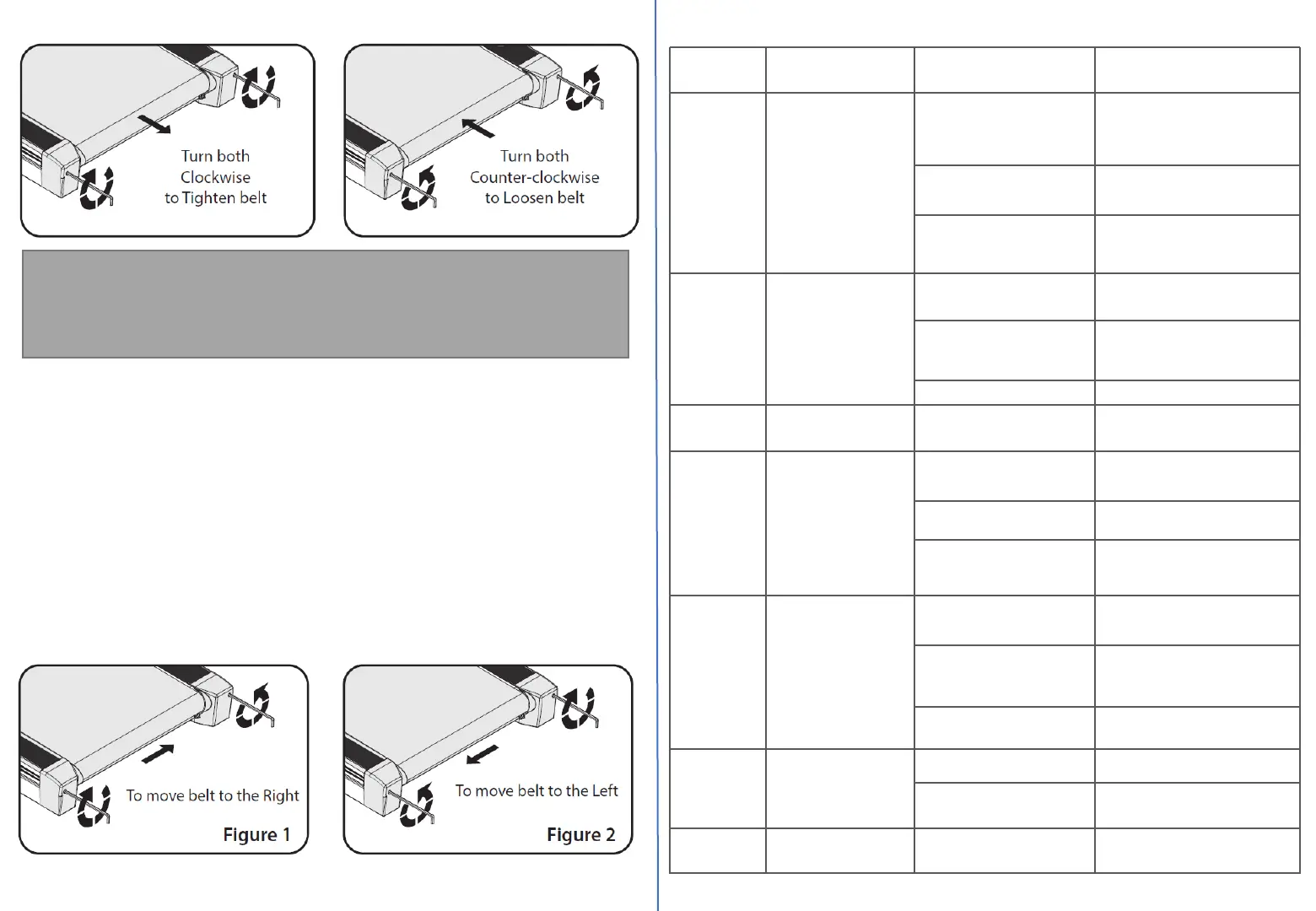

Belt Alignment

A. Press Start, then increase the treadmill speed to 3 mph (5 kph).

B. Stand behind the treadmill to see which way the belt is drifting.

C. If the belt drifts to the left, turn the left adjustment bolt 1/4 turn

clockwise and the right adjustment bolt 1/4 turn counter-clockwise.

(See FIG. 1)

D. If the belt drifts to the right, turn the left adjustment bolt 1/4 turn

counter-clockwise and the right adjustment bolt 1/4 turn clockwise.

(See FIG. 2)

E. Observe the alignment for two minutes. Repeat steps A-D as needed.

PROBLEM POSSIBLE CAUSE CHECKING CORRECTION

E01

Abnormal

communication

between the lower

controller and the

console after powering

on.

The console cables are not

connected well.

Connect the console cables

properly.

No signal output from the

console.

Change the console.

No signal output from the

lower controller.

Change the lower controller.

E02

Lower controller can’t

detect the voltage of

motor.

The motor cables are not

connected well.

Connect the motor cables

properly.

No voltage output or abnormal

voltage output from the lower

control to the motor.

Change the lower controller.

Motor is out of order. Change the motor.

E03

Lower control can’t

detect speed signal.

PWM drive circuit failure of

lower control

Change the lower controller.

E04

Overvoltage protection.

The load of the treadmill

exceeds the rated working

voltage of the motor.

The load on the treadmill must be

within the rated operational

voltage.

The treadmill motor works

abnormally.

Change the motor.

Detecting failure from the

lower controller to the motor

overvoltage.

Change the lower controller.

E05

Over current protection

The load of the treadmill

exceeds the rated working

current of the motor.

The load on the treadmill must be

within the rated operational

current.

Wrong assembly of the motor

causes the resistance or

blocking of the motor.

Check if the assembly of motor is

correct.

Failure of lower control limiting

current system.

Change the lower controller.

E06

Driving power supply

voltage is too low.

Voltage output is too low.

Check the power supply line is

normal.

The lower controller can not

detects the signal of the circuit.

Change the lower controller.

E07

Without Safety key

attached or failure

Check safety key attached or

not

Install the safety key

Troubleshooting

Loading...

Loading...