www.eikengineering.com

2.8.2 Inspect the track shoes for every 100 hours and make replacement if the part is

seriously damage and cannot be used anymore. Inspection rate must be more frequent

than normal especially when the machine has been operated on the land for a long

period.

NOTE: Track shoes are not limited for travelling on land only. Track shoes also are useful for

paddling on open water. With the large surface area and big in quantity, it creates huge amount

of resistance with water and help machine to move faster even without additional propelling

devices.

Track shoes also can protect the bottom surface of the pontoon from unseen dangerous items

when working in swampy or muddy areas such as sharp scrap metals, stumps or rocks.

IMPORTANT: Failure to make replacement of the damage track shoes can affect the pontoon

body and increase the cost for maintenance.

A track shoe life is varies substantially with different travel frequencies, quality of soil and water

and application method of the machine.

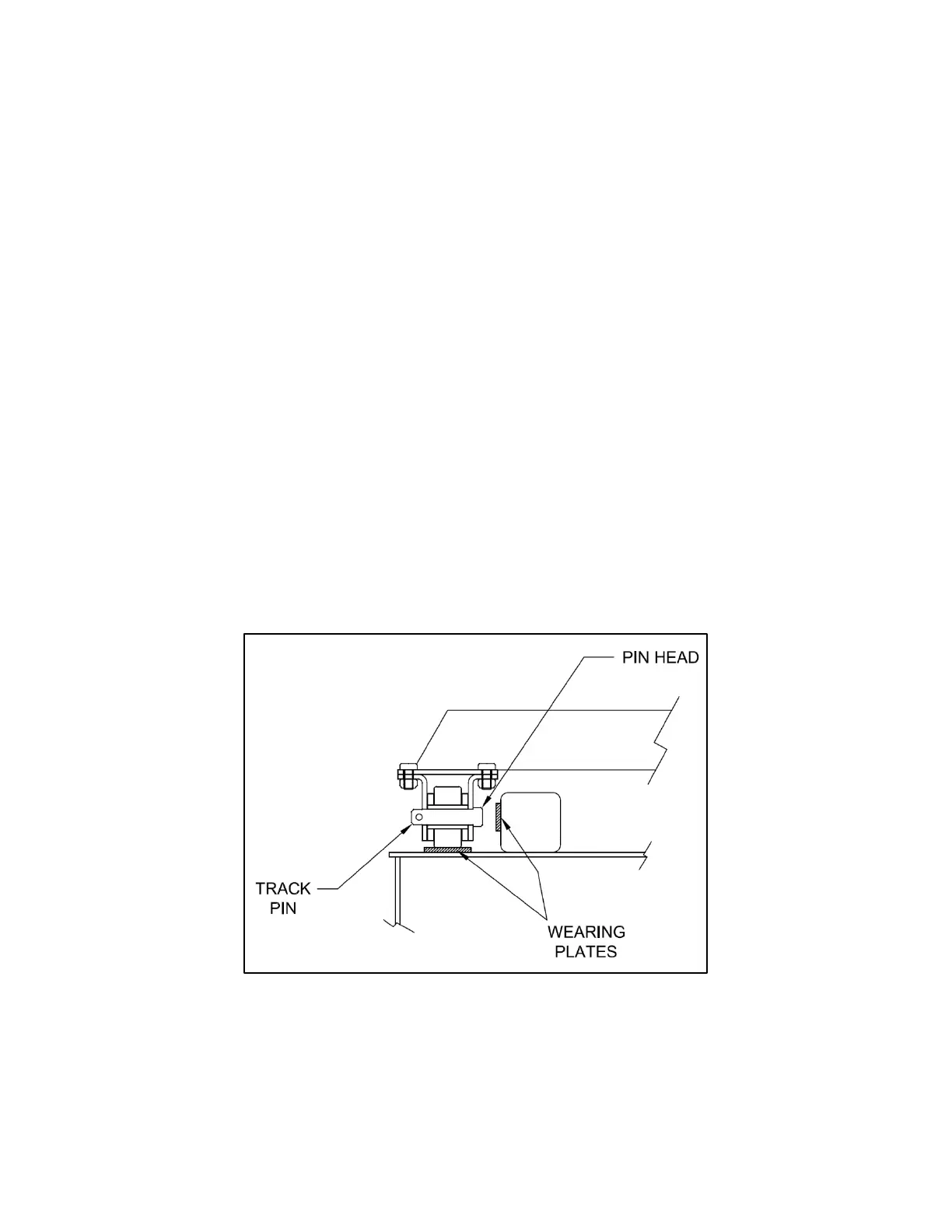

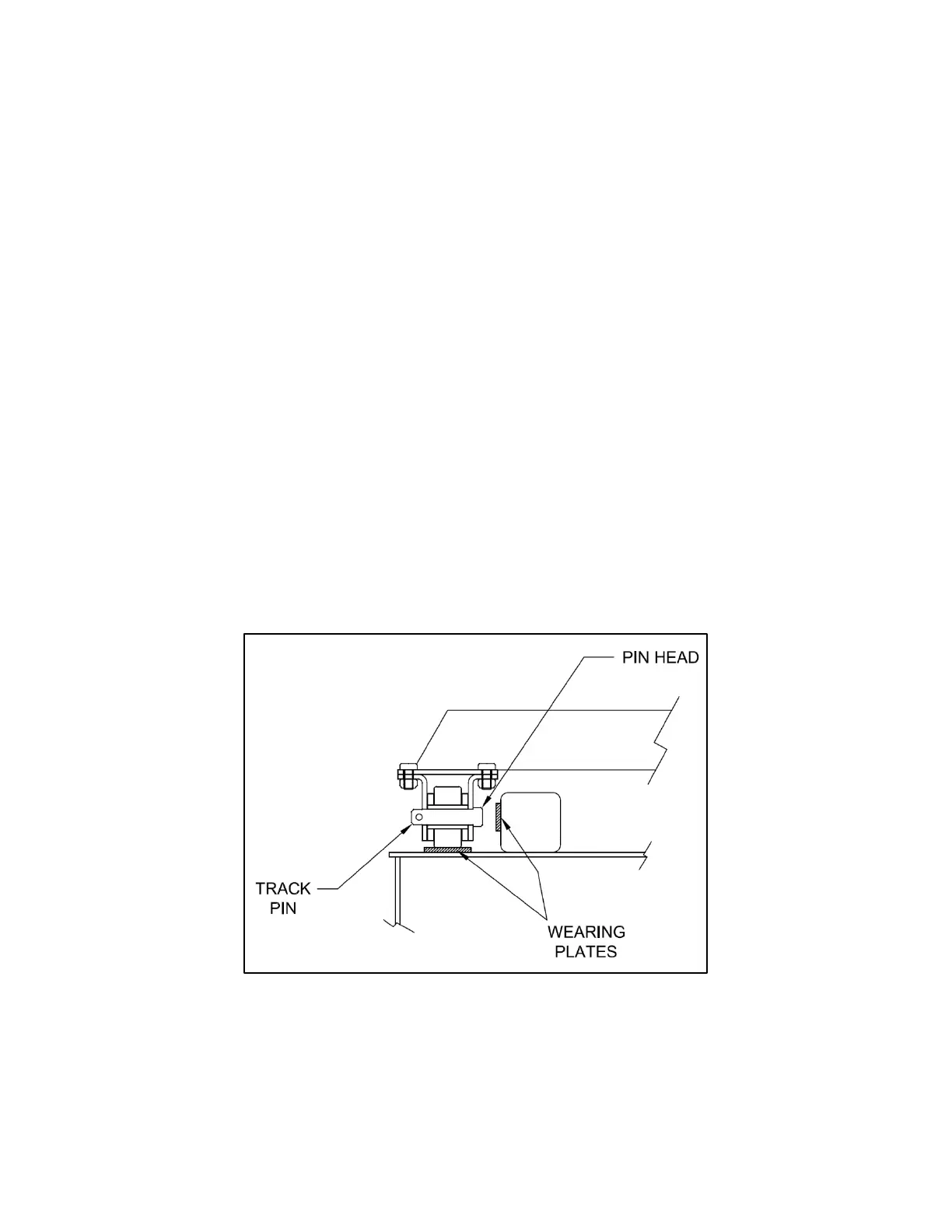

2.8.3 Change the track pins if the head are seriously wear. Replace the pin if the head

thickness wears until less than 4mm. For every 100 hours, the track pin head must be

inspected since the head is always contact and frictional with the wearing plate.

Figure 2.13

Loading...

Loading...