52 ELECRAFT

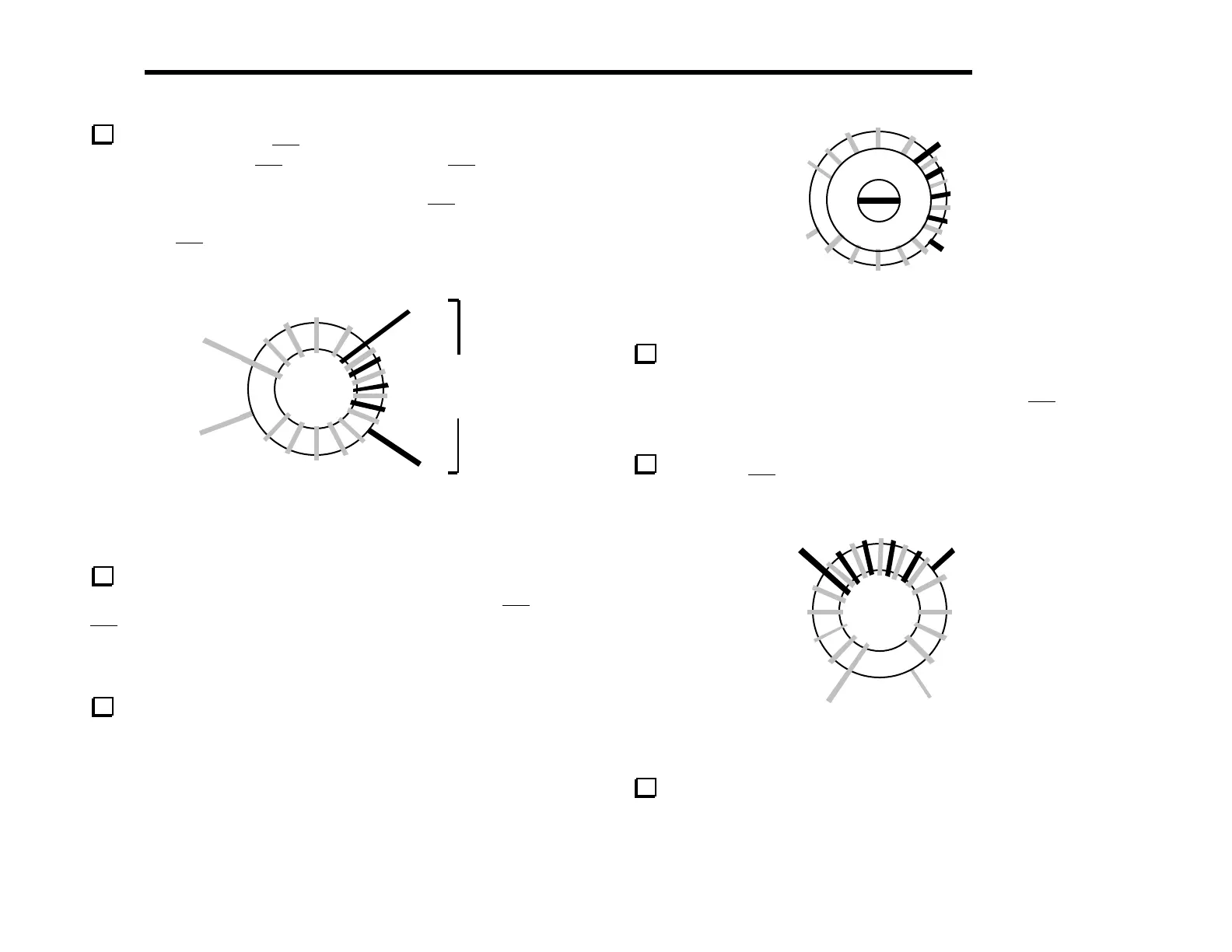

T5’s other winding, 3–4, uses 4 turns of green enamel wire

(7", 18 cm). Wind the 3–4 winding on top of the 1–2 winding,

interleaving the turns as shown in Figure 6-16. The turns should be

secure, not loose. Strip and tin the leads of the 3–4 winding.

Note: T5’s 3–4 winding must be wound exactly as illustrated

or the VFO will not function correctly.

Green,

4 turns

1

2

3

4

Figure 6-16

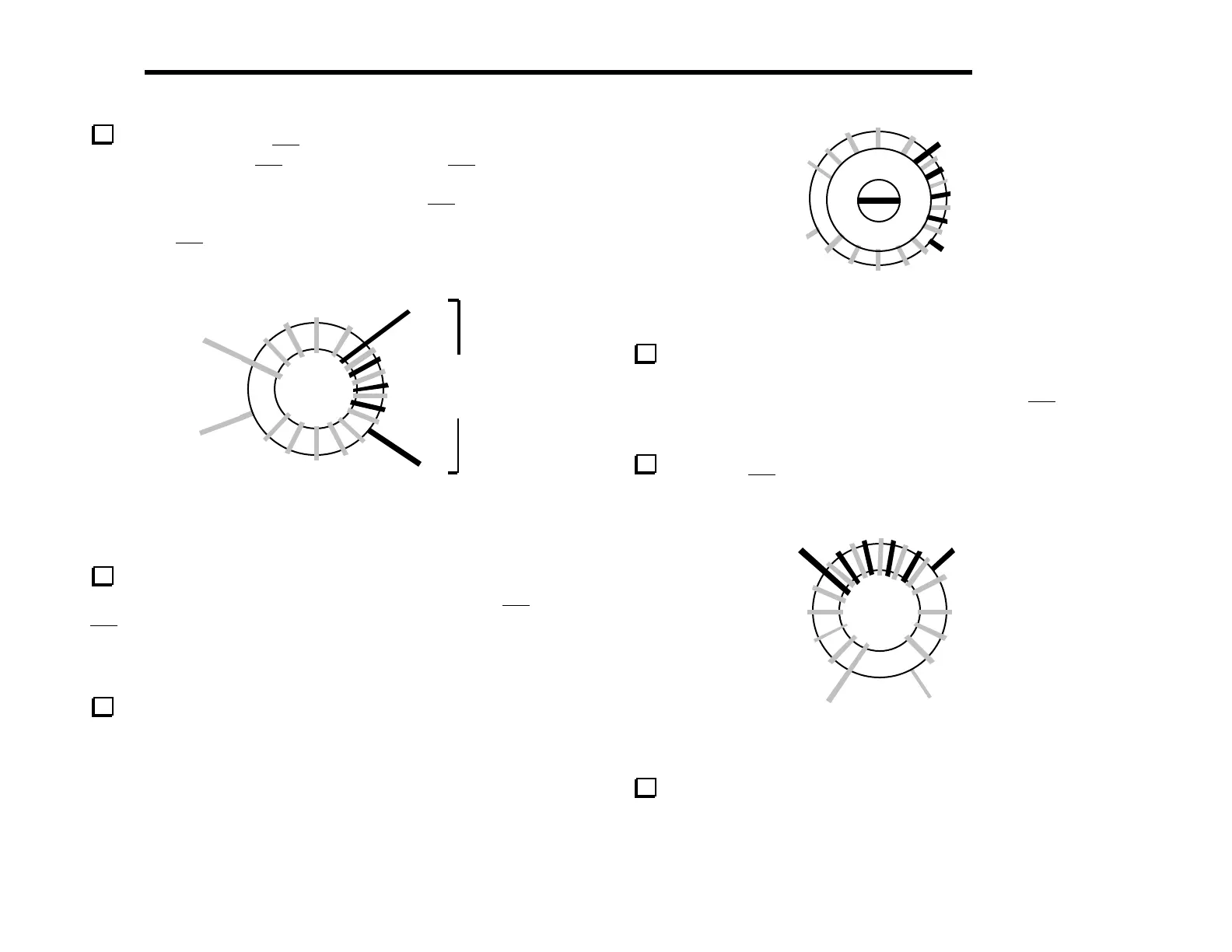

Install T5 as shown by its component outline in the

synthesizer area of the board. Figure 6-17 shows how the 1–2 and

3–4 windings are oriented with the numbered pads. (Also shown are

the nylon washer and screw, which will be installed in the next

step.) Pull T5’s leads taut on the bottom of the board, but do not

solder yet.

Secure T5 to the board as shown in Figure 6-17 using a 3/8"

(9.5 mm) diameter nylon washer, 1/2" (12.7 mm) long nylon 4-40

screw, and a #4 nylon nut. Tighten the nylon nut just enough to

hold the assembly in place. Do not over-tighten as this will strip

the threads. Solder T5, checking for good solder joints as before.

3

4

2

1

Figure 6-17

T7 is a toroidal transformer wound on a 3/8" (9.5 mm)

diameter ferrite core (dark gray, FT37-43). T7’s orientation and

windings will appear similar to Figure 6-18. Wind T7’s 3–4 winding

first, using 20 turns of red enamel wire (20", 51 cm). (The drawing

shows 14 turns.)

Wind T7's 1–2 winding using 5 turns of green enamel wire (6",

15 cm). Strip and tin the leads of both windings.

12

4

3

Figure 6-18

Install T7 as shown by its component outline near the front-

right corner of the board, with the windings oriented as shown in

Figure 6-18. Pull the leads taut on the bottom and solder.

Loading...

Loading...