56 ELECRAFT

Visual Inspection

Examine the bottom (solder side) of the RF board carefully for

unsoldered pins, solder bridges, or cold solder joints. Since this is a

large board, you should break the examination up into three parts:

__ perimeter of the board __ front half __ back half

Examine the top (component side) of the RF board for

unsoldered pins, solder bridges, or cold solder joints. This step is

necessary because some components are installed on the bottom of

the board.

Make sure switch S1 on the RF board is in the OFF position.

(Plunger OUT is OFF.)

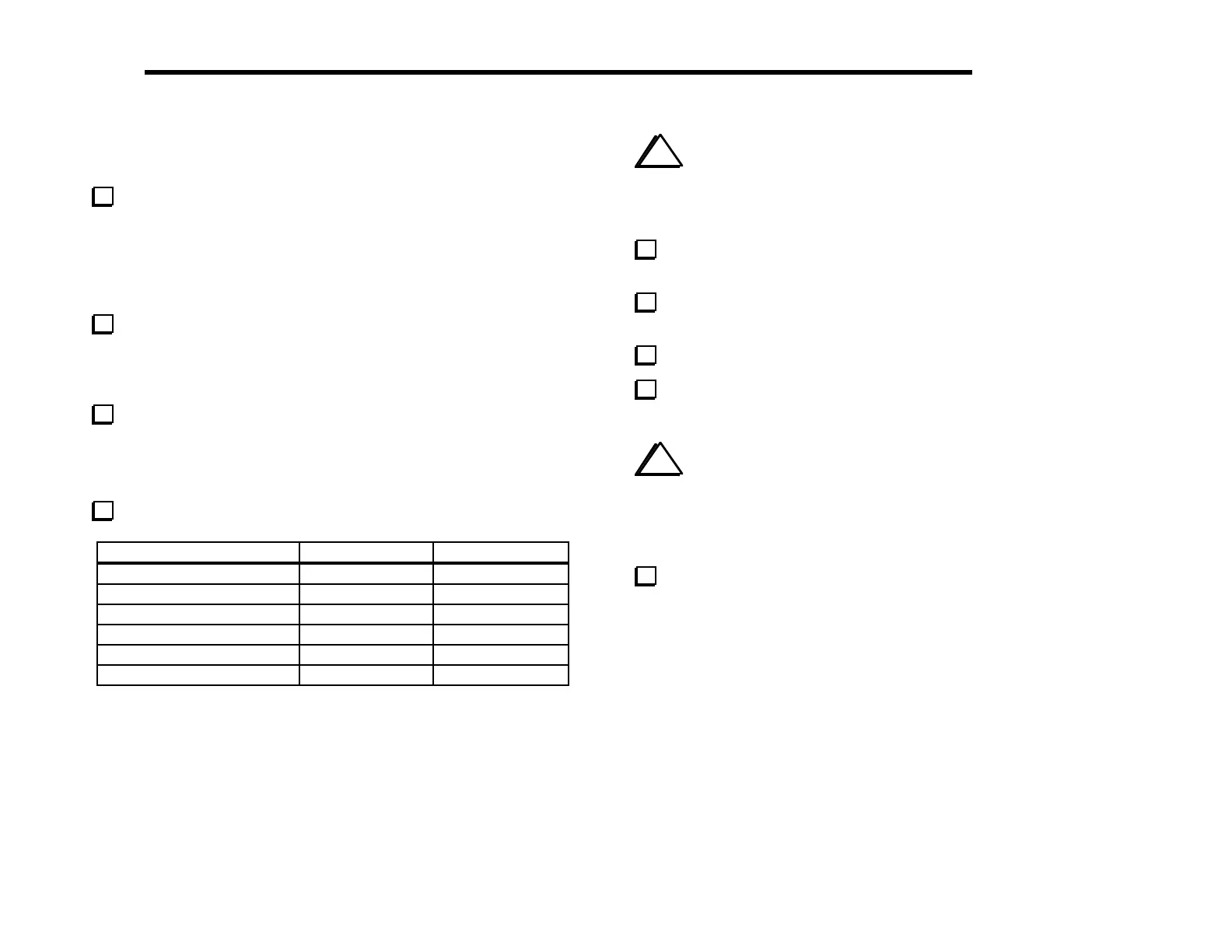

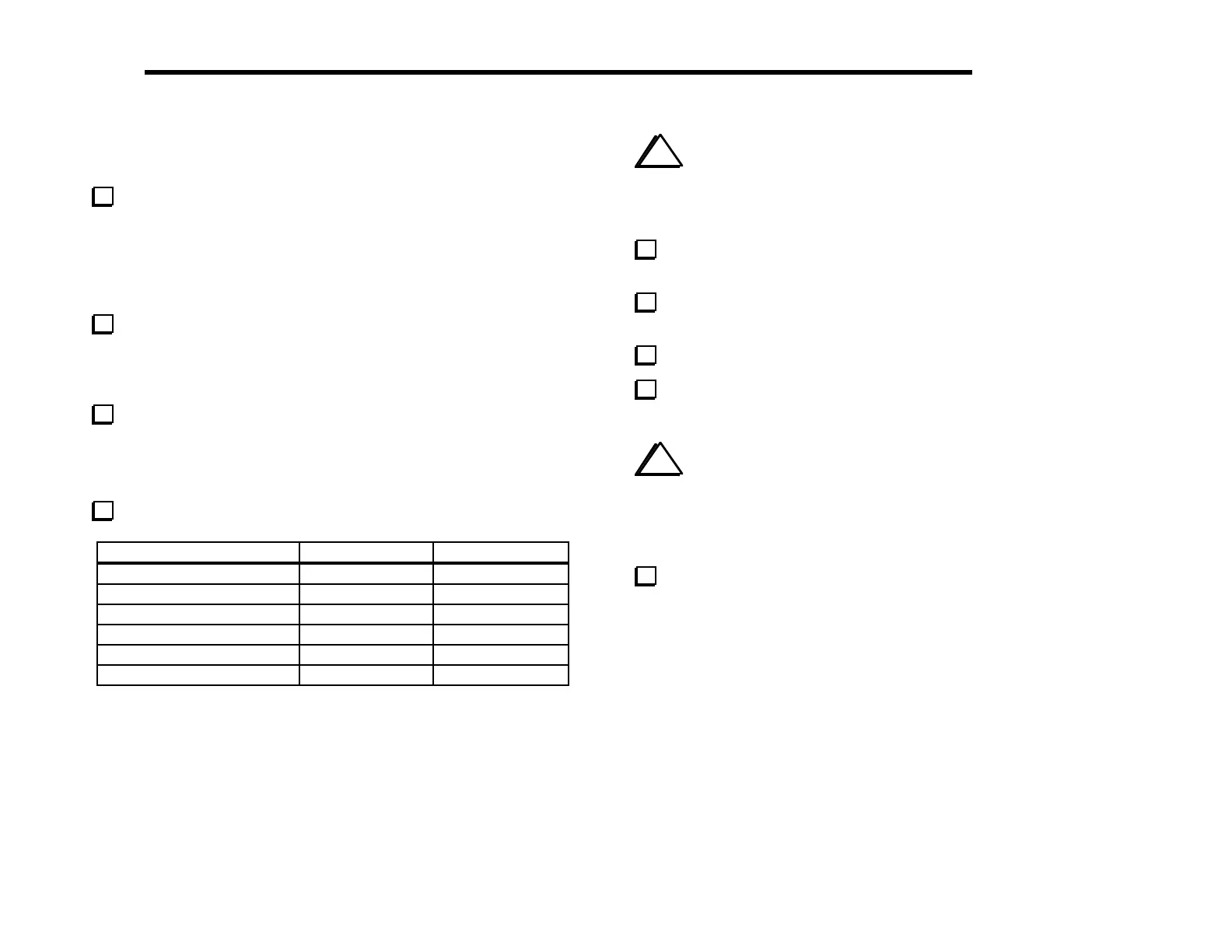

Resistance Checks

Perform the following resistance checks:

Test Point Signal Name Res.

to GND

R115, ri

ht end

near S1

12V IN > 500 ohms

U6 pin 8 8B > 100 ohms

U4 pin 16 5B > 1 k

U11 pin 8 8A > 250 ohms

U10 pin 8 8 T > 500 ohms

U12 pin 1 8R > 500 ohms

i

It is very important to re-assemble the chassis as described

below before attempting the alignment steps in the next section. If

you don’t put the chassis together, some alignment results will not

be accurate.

Install the two side panels and secure with two chassis screws

each.

Plug in the front panel assembly. Secure the front panel with

four chassis screws.

Plug in the Control board.

Secure the front panel and Control boards together using two

chassis screws.

i

Before installing the bottom cover in the following step,

verify that all components on the bottom of the RF board have an

installed height of 1/4" (6 mm) or less. Capacitors that stand above

this height must be bent downward at an angle to prevent them

from hitting the bottom cover.

Install the bottom cover and secure it temporarily using six

chassis screws.

Loading...

Loading...