16

8. OPERATING PROCEDURE

8.1. Open the RMT door and take the tape drive mechanism out, for what press

simultaneously the two levers situated in the both sides of the mechanism. Released mechanism

turns forward and can be easily taken out.

8.2. Installation of the recording devices

8.2.1. Switch the device on.

8.2.2. Insert the recording device for the first measuring channel in the holder. Repeat

operations for two other measuring channels. The ink of recording devices has different colors for

each measuring channel.

Recording devices removal during their replacement is made in the reversed order.

8.2.3. The auxiliary paper stopper for the electric motor (used during RMT storage or

transportation) should be removed during the above described operations with the recording devices

8.3. The diagram moving speed is controlled by the switch located in the RMT bottom part.

During this operation the tape drive mechanism should be taken out.

With the help of the switch it is possible to choose one from two numbers(lines) of speeds of

the diagram moving: 10+240 mm / hour or 10+240 mm / minute (600+1400 mm / hour).

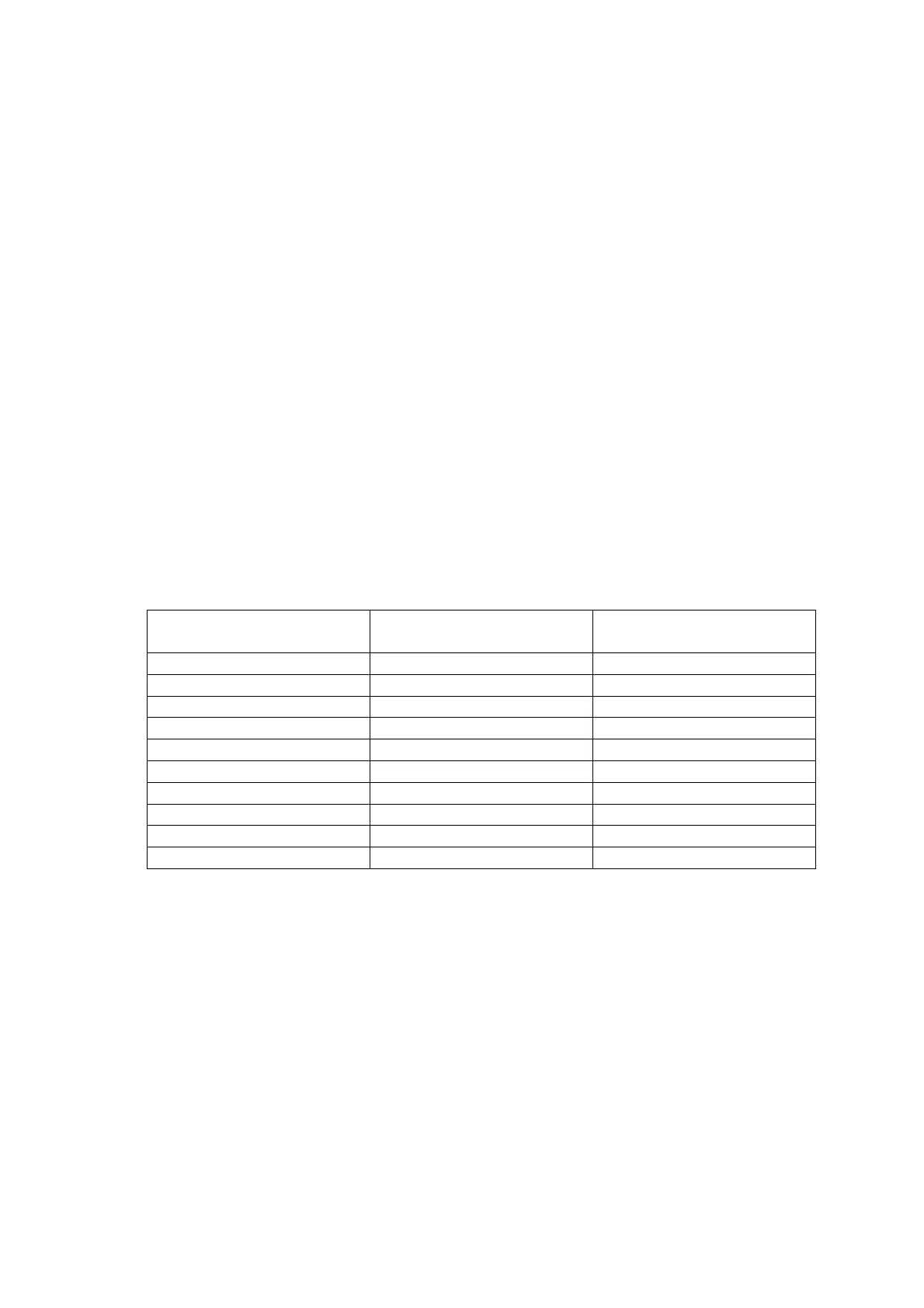

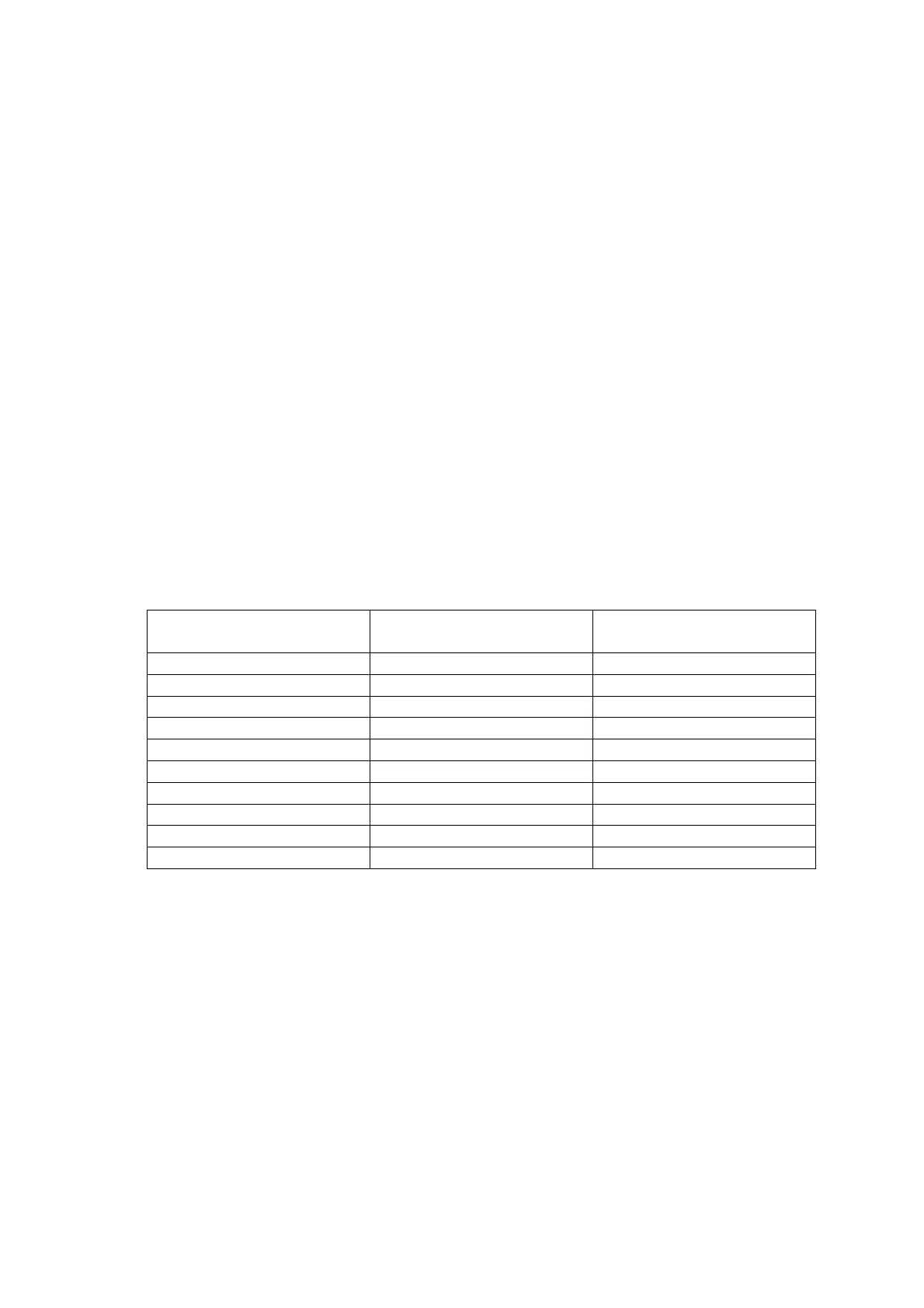

Dependence of one plotting paper roll operating time duration and of time of record presence

in the field of vision is indicated in the table 4.

Table 4

plotting paper moving

speed mm / hour

operating time time of presence of record

in the field of vision

10 66 days 8 hours

20 33 days 4 hours

60 11 days 80 minutes

120 5,5 days 40 minutes

240 66 hours 20 minutes.

600 26 hours 8 minutes

1200 13 hours 4 minutes

3600 260 hours 80 seconds.

7200 130 hours 40 seconds

14400 66 minutes 20 seconds.

8.4. Preparation for working with rolled plotting paper

8.4.1. Open a roll of plotting paper. Insert the giving spool into the roll and establish them in

grooves located behind the top part of the tape drive mechanism.

8.4.2. Pass the beginning of plotting paper under the holding rod, then stretch the paper atop

of the transporting gear rollers, pass it under the transparent transport rod, under the bottom

directing bar and insert it in the slots of the reeling up (accepting) spool.

8.4.3. Turning the receiving spool approximately on 2 turnovers, roll the paper up very

tightly.

8.5. Insert the tape drive mechanism into the grooves of the forepart of the put forward RMT.

Establish by rotation the tape drive mechanism in its initial position.

Loading...

Loading...