12 5041 2E22

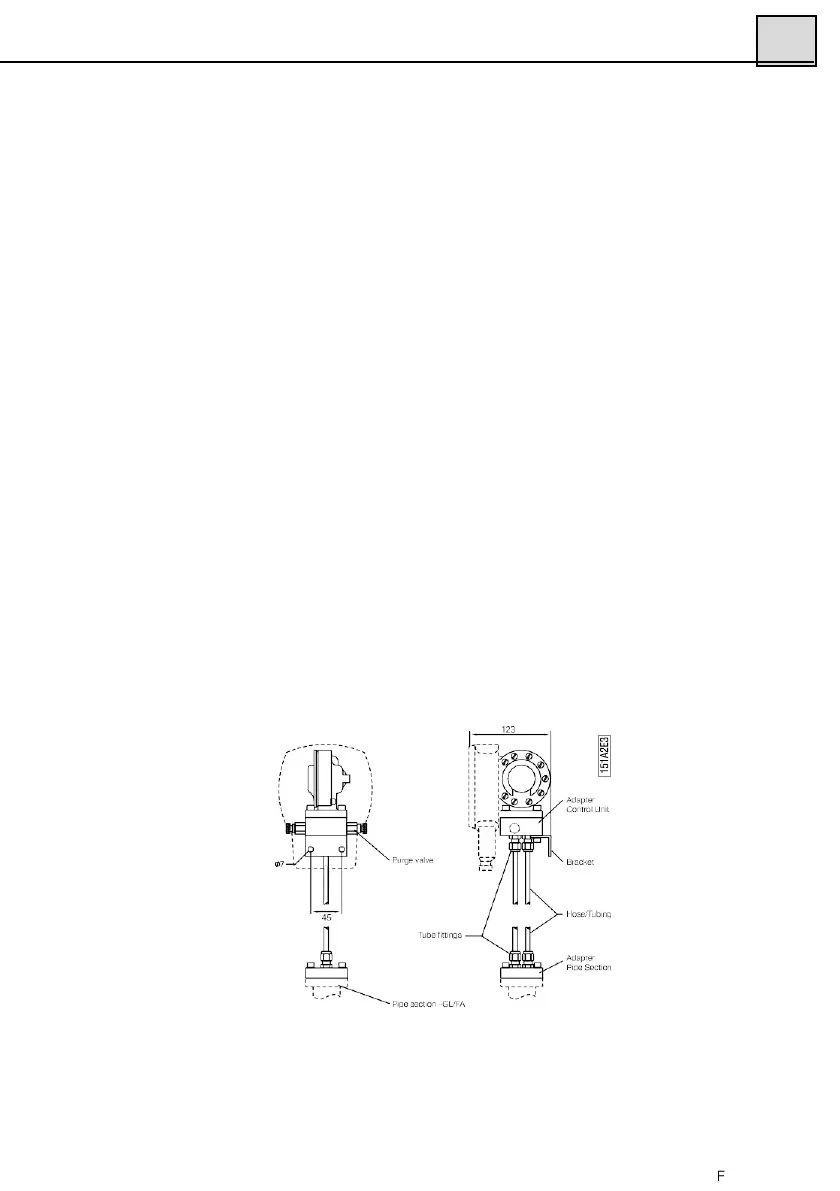

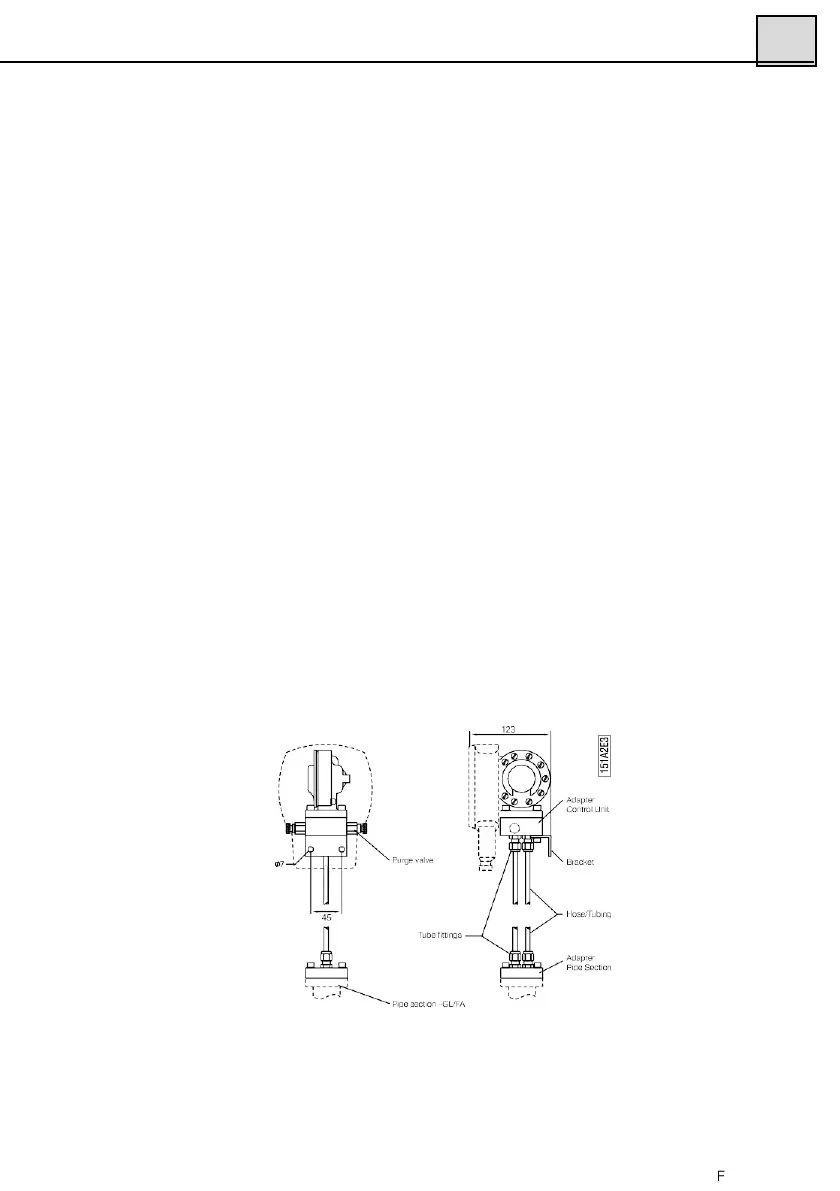

ports up to the Control Unit, it is also possible to separate the Monitor (Fig.

2) from the Pipe Section -GL/FA into two parts. The pressure is then lead

through either plastic hoses or metallic tubing depending on the liquid,

pressure and temperature.

As a standard, we supply 2x1,75 meter (5.74 feet) of PA plastic, Ø 6 mm (0,23

inch) hoses capable of handling 90ºC (194°F) and 16 bar (232 PSI), together

with two specially made adapters to be mounted on the Pipe Section and

Control Unit respectively. If your application requires metallic tubing (copper

or stainless steel) it has to be provided locally. If you are measuring a chemi-

cal liquid or gas, check with the supplier which material you should use in

your tubing. Please make sure to use only 6 mm tubing in order to suit the tube

fittings included in the delivery. There is no actual limitation in the length of

the hoses or tubing, but we recommend placing the units as close as possible

to each other, as this will help in troubleshooting and on-site calibration.

Note!!! The hoses/tubings must have the same length to avoid uneven pres-

sure. If you mount valves (not included in delivery) in the pressure hoses/tu-

bing, it will help you to easily shut them off and remove/exchange the

Control Unit at full process pressure.

Please follow the above ”Installation of the Pipe Section” after you have

mounted the adapter on to the Pipe Section. As you will use hoses/tubing to

lead the pressure up to the Control Unit, it is possible to mount the Pipe

Section in any direction, vertically or horizontally and with the pressure ports

pointing up, down or to the side (pls. see section 2.3).

Separate mounting of Pipe Section and Control Unit GL/FA

Figure 2

Loading...

Loading...