::

1

..

2

pag.7.

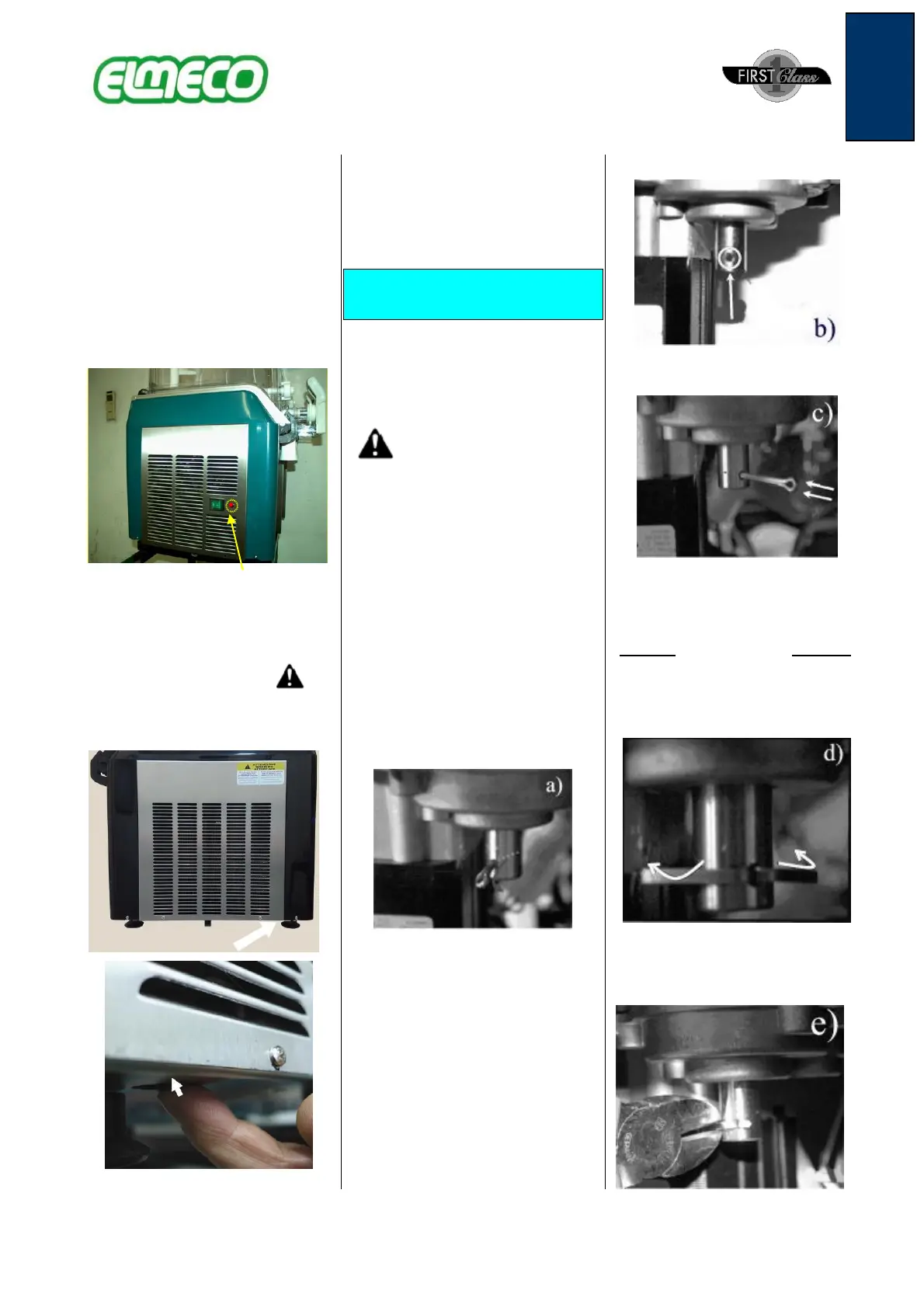

Cotter pin substitution

If the machine works but the augers do

not turn, it is possible that the cotter

pin, (item 35 of the exploded view in

appendix-23) that connects the gear

motor to the transmission shaft, broke

down.

Disconnect the power electric

cable

After removing the back and side

panels, you can see the breakdown

trying to lift the ring that fix the vertical

auger (item 28 of the exploded view in

appendix-23). It can happen that it is

blocked or that, if you lift it, it carries

away the transmission shaft with it

(item 29 of the exploded view in

appendix-23).

In the first case, it is necessary to

control that the transmission shaft

base is as high as the gear motor (exit

shaft). The lift pin could be in the hole

of the gear motor slow shaft but it

should be deformed or broken (see pic

.a)

In the second case, the hole in the

gear motor should be completely

empty and some remnants of the split

pin will certainly lie in the machine.

It is therefore necessary to install a

new split pin.

Place the transmission shaft so as its

hole is aligned with the one present on

the gear motor exit shaft; it should be

evident when they are aligned;

Insert the split pin as shown in the pic.

c;

verify that the head of the split pin, in

its rotation, does not touch the gear

motor and respects a minimum

distance.

Warning: do not reuse, in any case,

the old split pin

With the help of a pliers, fold the two

ends of the split pin downward as

indicated by the arrows in the pic. d;

Then, with nippers, cut the extremities

in excess in order to avoid a contact

with the gear motor during the rotation

(see pic. e).

Loading...

Loading...