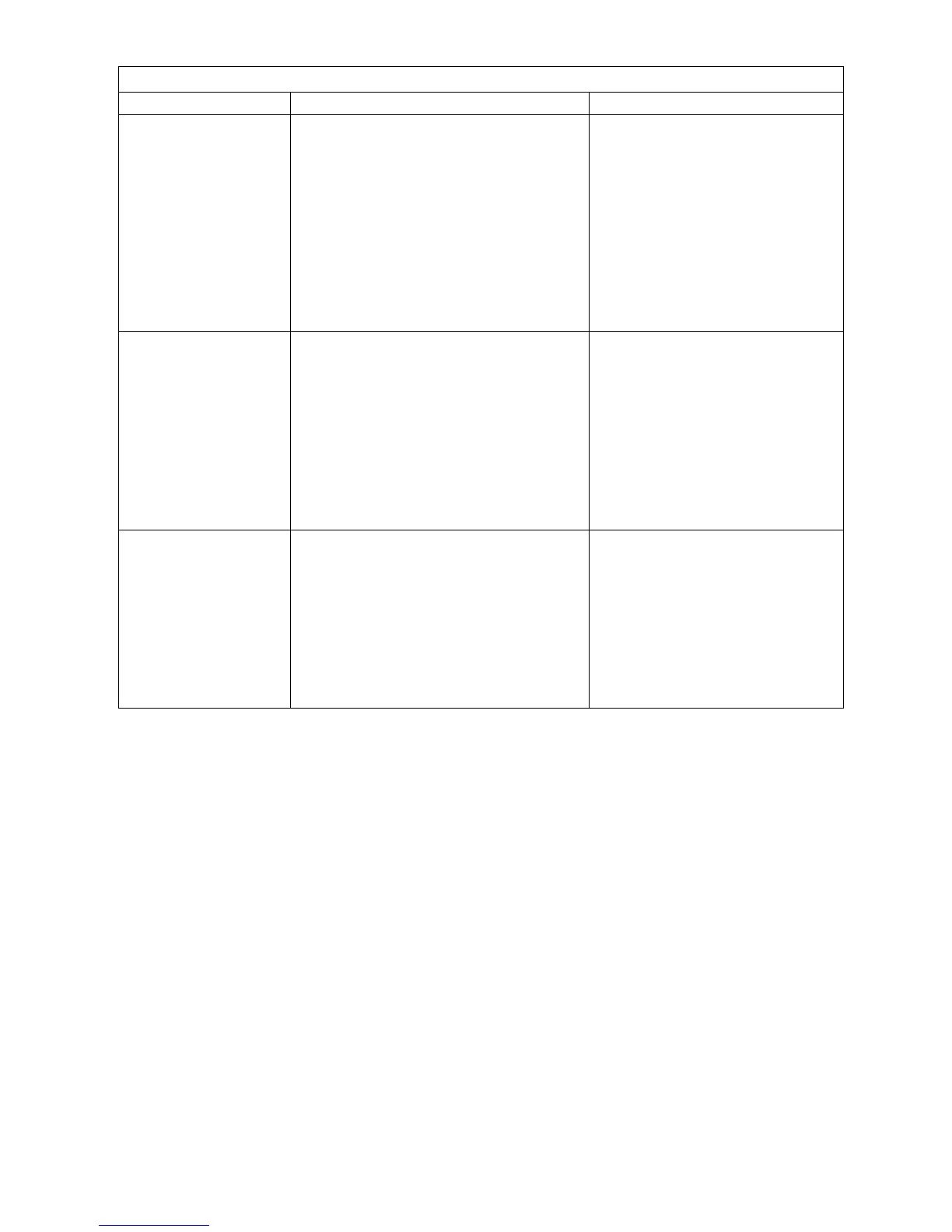

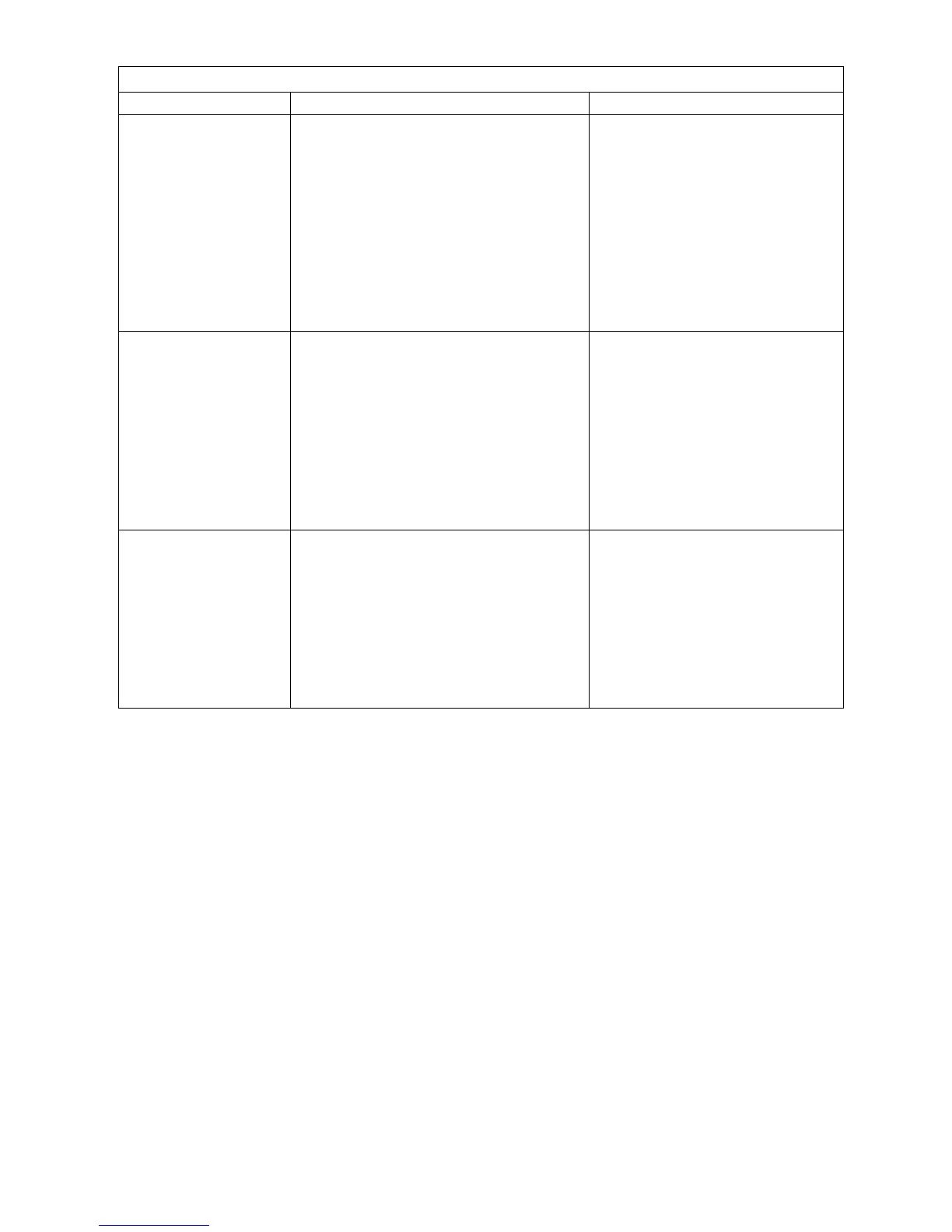

TROUBLE SHOOTING

Trouble Cause Remedy

Breaking needle 1. Needle touches plate.

2. Needle is bent or blunt.

3. Needle touches shuttle hook.

4. Machine feeds while needle is in

fabric or zigzag timing is not

correct.

5. Fabric is pulled while sewing.

Adjust the needle drop see

page 11.

Replace with a new needle.

Adjust the clearance between

needle and shuttle hook see

page 15.

Adjust the zigzag timing see

page 10.

Do not pull the fabric while

sewing.

Machine is noisy 1. Backlash between lower shaft

and hook driver gears is not

appropriate.

2. Too much play on lower shaft

3. Motor belt tension is too tight.

4. Too much upper shaft play.

5. Lack of oil.

Adjust the backlash see page

15

Reduce the play.

Adjust the motor belt tension

see page 26.

Reduce the upper shaft play.

Apply a few drops of oil on all

moving parts.

Distorted stitch

pattern.

1. Zigzag timing is not appropriate.

2. Cam follower is not released

enough.

3. Needle thread tension is too tight.

4. Stretch stitch feed is not

balanced.

Adjust the zigzag timing see

page 10.

Adjust the cam follower see

page 22.

Adjust the needle thread

tension see page 7.

Adjust the balance see page

20.

3

Loading...

Loading...