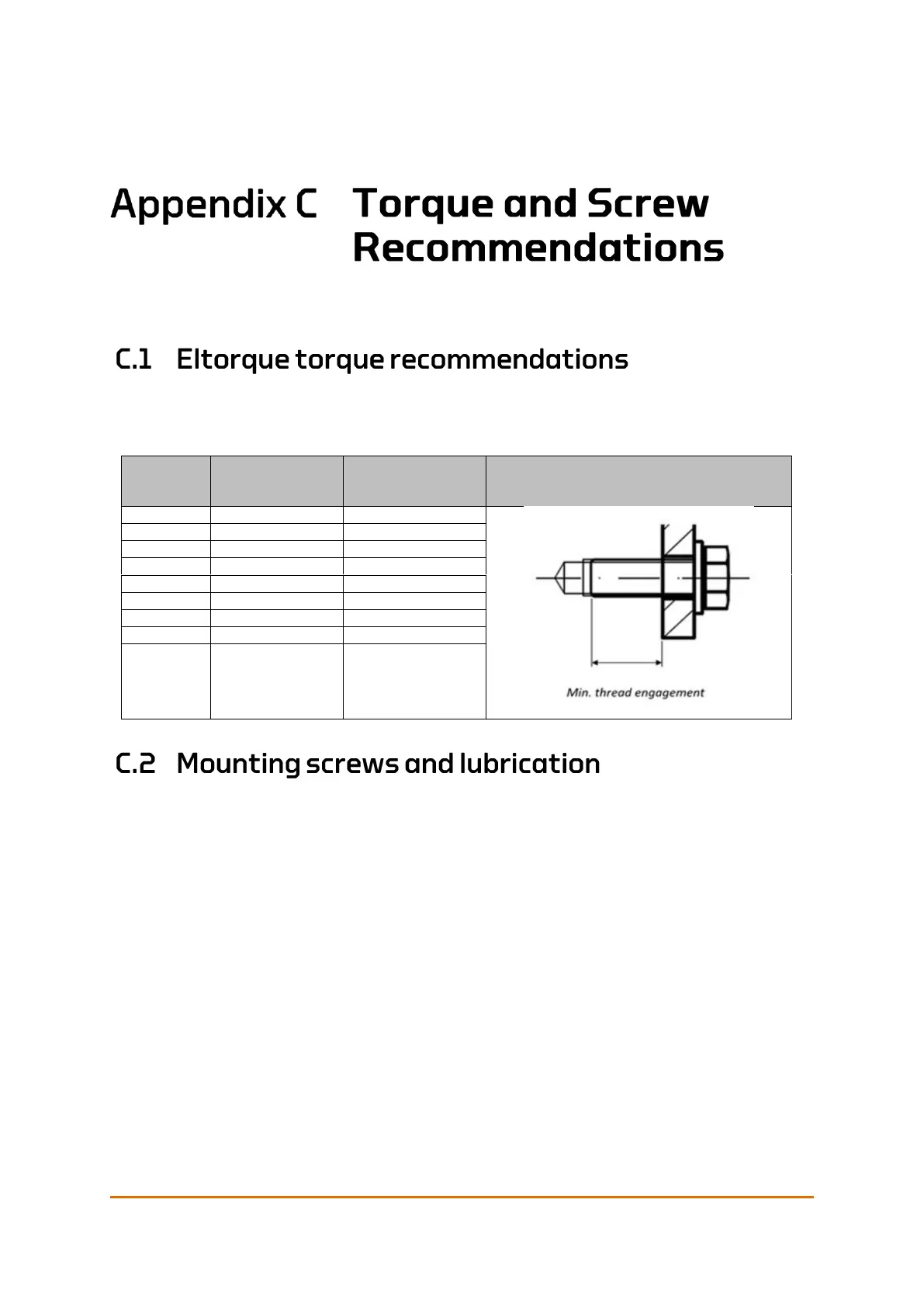

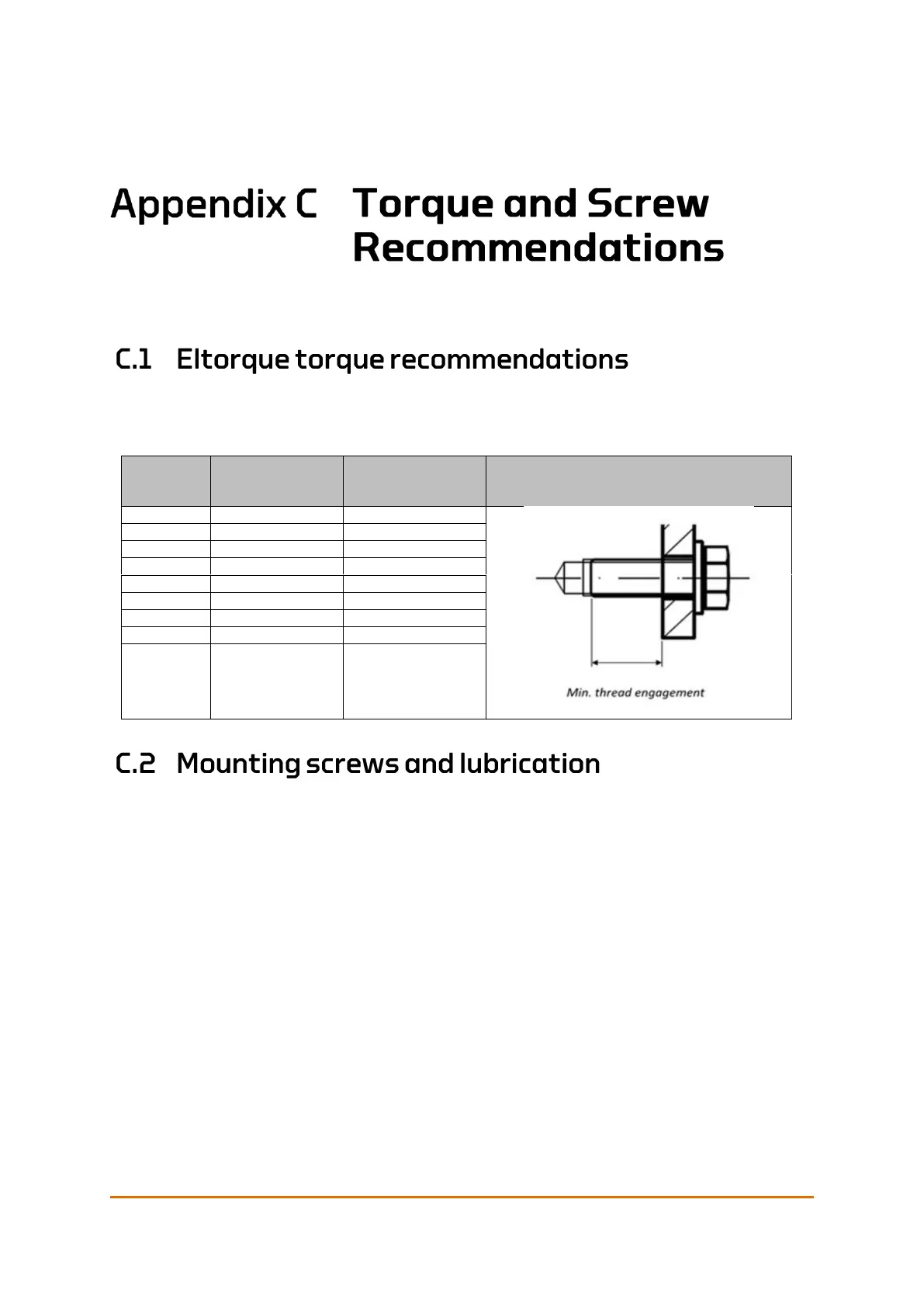

The following table lists recommended torque values and minimum thread

engagement when mounting the Eltorque actuators.

Table 22: Screw torque

• Use A4-80 screw material and quality.

• Use washer under bolt head/between bolt head and mounting flange.

Requirements: DIN 125A, minimum 200HV, A4.

• Lubricate washer surface and underside of bolt head with a lubricant

resulting with a friction coefficient 0.08 to 0.14 between bolt head and

washer. The lubricant must not contain aluminum, zinc or copper. To

prevent galling when using stainless steel fasteners, lubricant containing

MoS

2

is recommended.

• Use thread lock Loctite 222 or similar, on bolt threads. Be sure that the

amount applied is enough, so no water can get into thread holes after the

bolt is inserted. The thread-lock’s main purpose in this application is to

serve as a barrier, preventing sea-water to act as a catalyst between bolts

and threads in the actuator base.

Loading...

Loading...