C6.2.7/0302-0903/E 7

6 Refrigerant Migration

Due to the Scroll’s inherentability to handle liquid refrigerant in flooded start and defrost cycle operation, an

accumulator may not be required. For single compressor systems with extremely large charges greater than 4,5 kg,

an accumulator is recommended. Excessive liquid refrigerant flood- back during normal off cycles, defrost cycles, or

steady operation can dilute the oil in any compressor causing inadequate lubrication and bearing wear. Proper system

design will ensure maximum compressor life.

Due to the high starting torque of three phase Scroll compressors any excessive amounts of refrigerant that have

migrated into the shell during stand-still periods must be driven out of it prior to start-up. Crankcase heaters are

required on outdoor systems where the charge limits exceed the above value. Crankcase heaters should also be

used when compressor packs are installed outdoors.

7 Crankcase Heaters

Equipment for heating the oil in the crankcase is necessary if the system configuration enables large amounts of

refrigerant to condense in the compressor and be absorbed by the oil. At the high temperature produced by the heater

refrigerant is constantly vaporised and problems in oil supply are reduced. The wrap around band heater should be

positioned between the left-hand side of the oil sight glass and the electrical box (see fig. 2 DTC valve assembly

procedure).

8 Discharge Temperature Protection

Internal discharge temperatures reached under some extreme operating

conditions such as loss of refrigerant injection charge or extremely high

compression ratio could cause compressor damage.

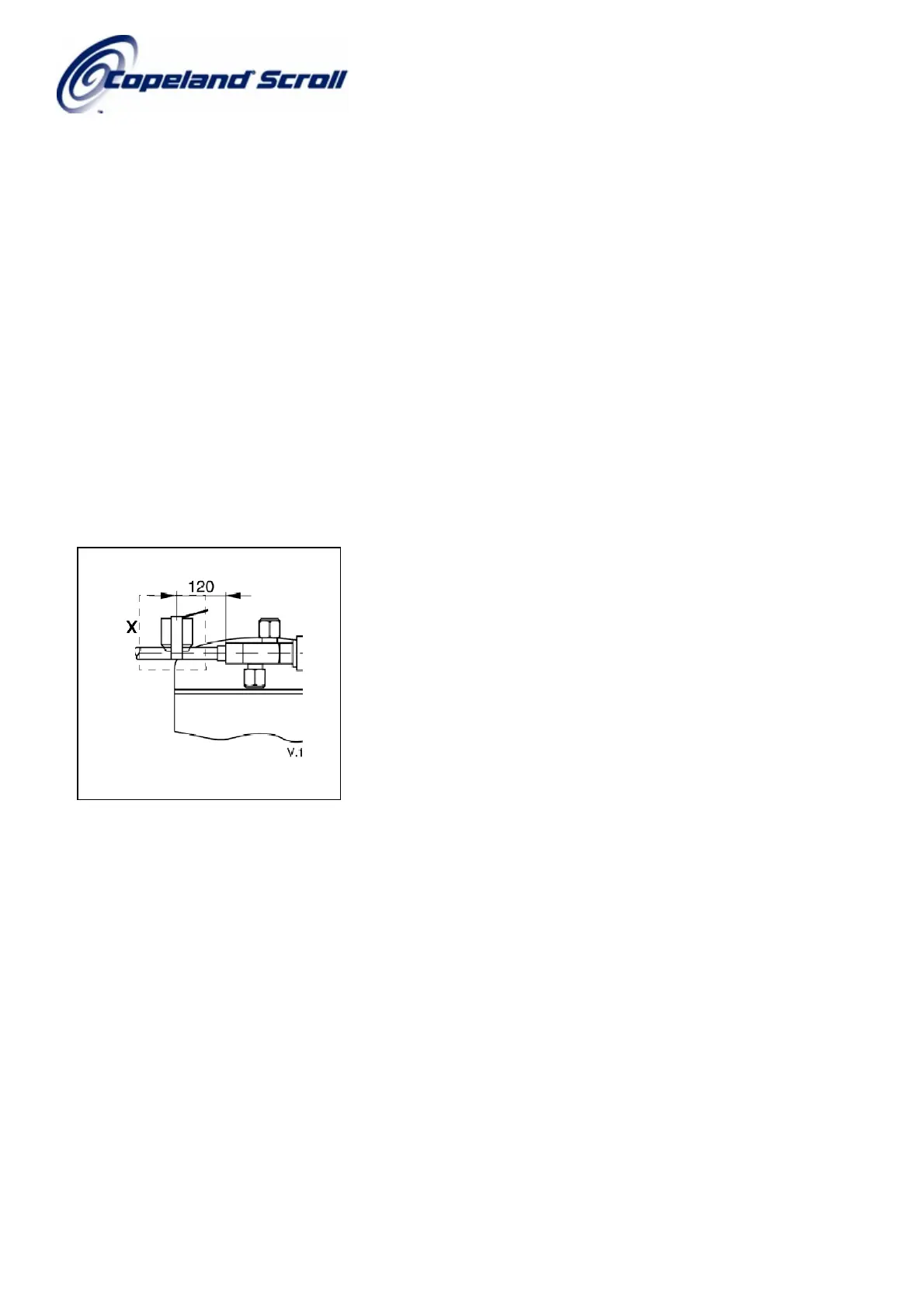

For this reason Copeland recommends THERM-O-DISC thermostat

37TJ31 X 1976E on all horizontal refrigeration scroll compressors.

This thermostat has a cut-out setting of 99 °C ± 4 K with 28 ± 5 K closing

differential and should be installed approximately 120 mm from the

discharge valve outlet (see figure 3).

In order to avoid improper functioning due to false readings this thermostat

needs to be insulated (see “X” in figure 3).

Figure 1: Discharge Line Thermostat Location

9 Standard Motor Protection

Conventional inherent internal line break motor protection is provided with all horizontal refrigeration scrolls.

10 Mufflers

Flow through Copeland Scroll compressors is continuous and has relatively low pulsations. External mufflers,

previously applied to piston compressors, may not be required for Copeland Scrolls. Because of variability between

systems, however, individual system tests should be performed to verify acceptability of sound performance.

11 Low Ambient cut-out

A low ambient cut-out is not required to limit heat pump operation.

Loading...

Loading...