8 C6.2.38/0719/E

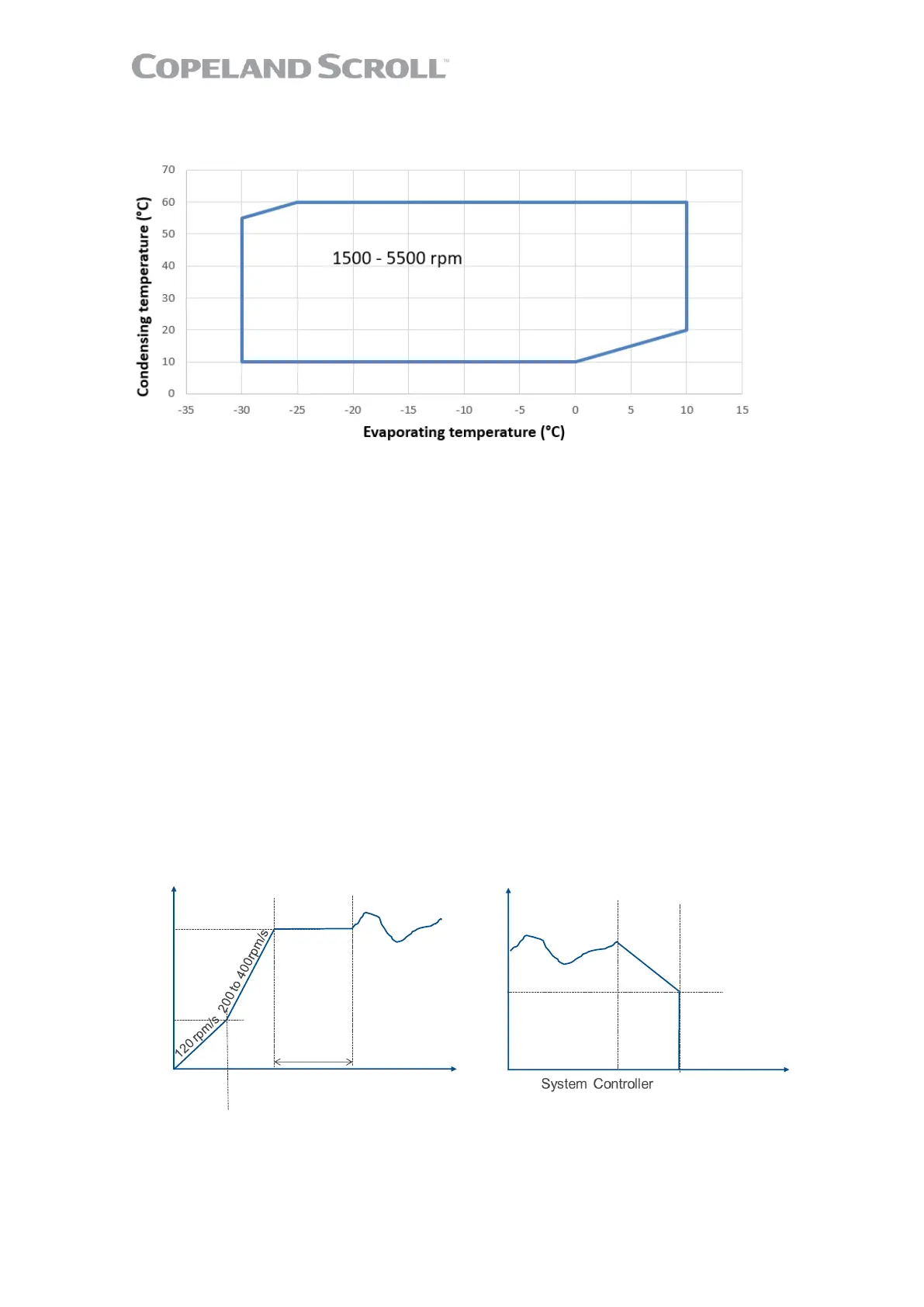

The lower right boundary of the operating envelope is the minimum compression ratio required to keep

the scrolls loaded. Operation below this limit could

result in the compressor intermittently loading

and unloading and noisy operation.

Figure 6: R290 application envelope for YBVH* compressors with 10K suction superheat, 25-92 Hz

Please note some comments about the envelope:

▪ Before compressor start with the matched pair of YBVH* and the ED3 drive, the pressure

difference in the system has to be below 10 bar. If the pressure difference is reduced by opening

the expansion valve, care must be taken to avoid liquid flood back to the compressor – also see

oil dilution chart in Figure 5.

▪ An oil return test for the system must be performed. If required, the system design must be

improved to ensure sufficient oil return from the system to the compressor – also see Chapter

2.6.3 "Oil filling and oil level".

▪ The use of 1500 rpm for low condensing and high evaporating temperatures is possible as shown

in the envelope.

▪ The system should be able to bring the compressor to a point inside the envelope as fast as

possible at the start, and to keep the compressor running there. Running outside the envelope is

not allowed.

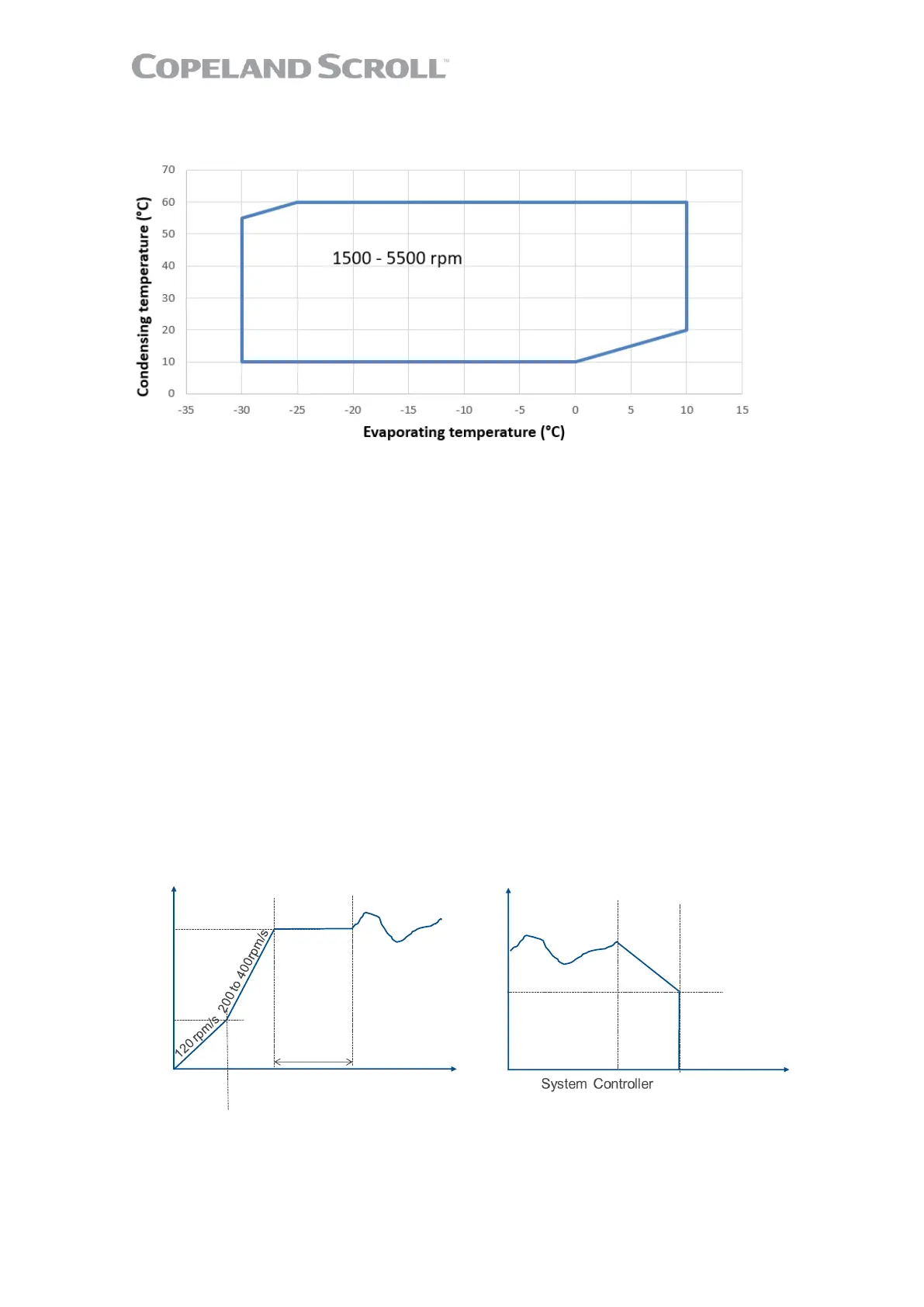

▪ At start-up the system should be able to bring the compressor to a point inside the envelope as

fast as possible and to keep the compressor running there. Running outside the envelope is not

allowed. Emerson’s recommendation is to start with a speed of 3000 rpm and to freeze the speed

for minimum 30 seconds or longer until the system is in stable operation – see Figure 7 "Ramp

up".

Figure 7: Ramp up and controlled shutdown

▪ Running/oscillating the compressor in and out of the envelope borders is not allowed and should

be avoided.

Loading...

Loading...