AGL_HP_VS_YHV2P_E_Rev0 13

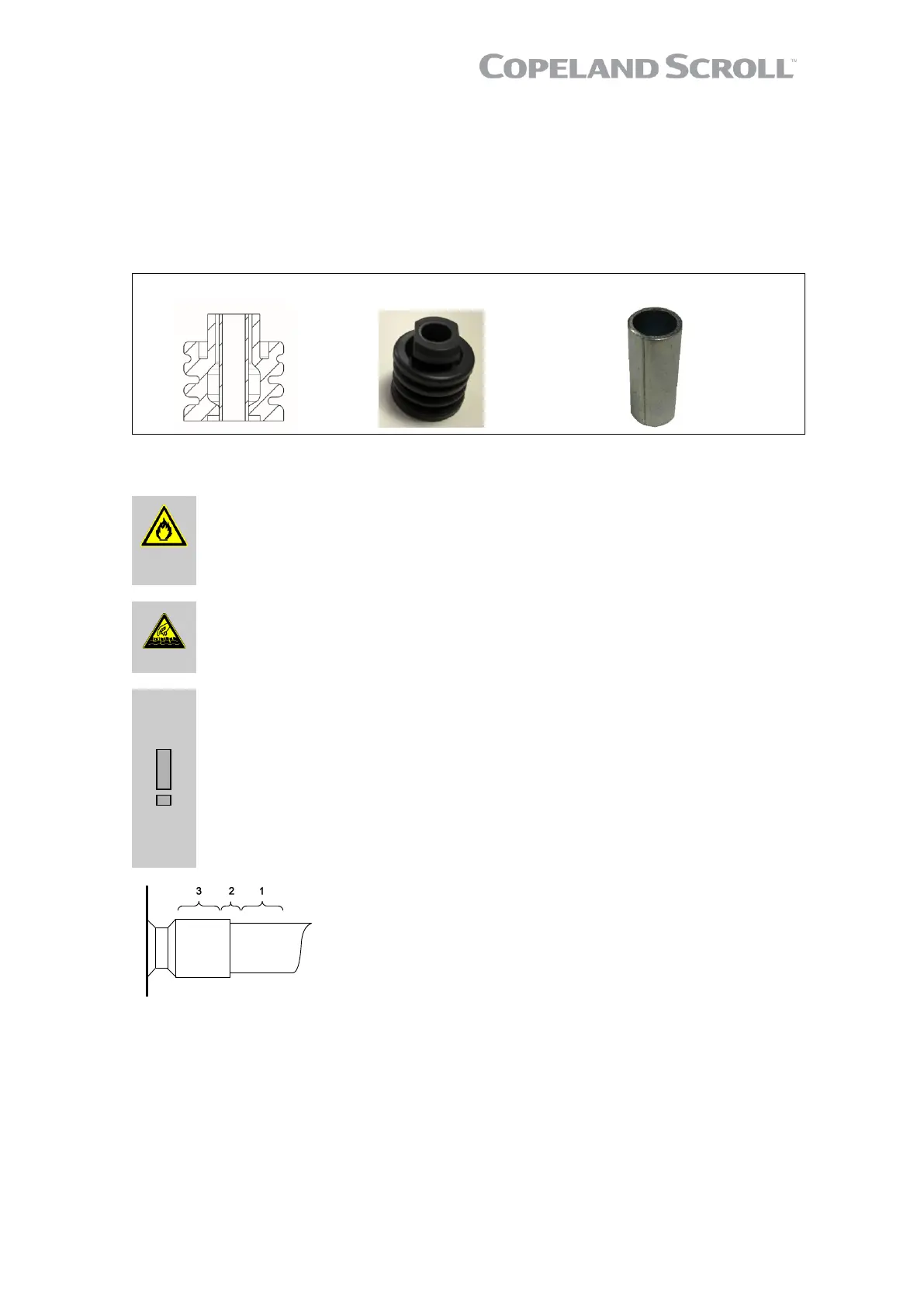

3.1.4 Compressor mounting parts

The compressors are designed to be mounted on vibration absorber grommets (part of the standard

delivery). The grommets dampen the start-up surge of the compressor and minimise sound and

vibration transmission to the compressor base during operation. The metal sleeve inside is a guide

designed to hold the grommet in place. It is not designed as a load-bearing member, and application

of excessive torque to the bolts can crush the sleeve. Its inner diameter is approximately 8.5 mm to

suit a M8 screw. The mounting torque should be 13 ± 1 Nm. It is critically important that the grommet

is not compressed.

Mounting parts YHV*2P – Soft mountings

Figure 13: Rubber mounting part with sleeve

3.2 Compressor brazing procedure

WARNING

Air/flammable refrigerant mixture! Creation of a potentially flammable

atmosphere! Fire hazard! Remove all refrigerant before opening the system.

When working on a refrigerant-filled system, make sure to follow the safety

and working instructions given in the Chapter 6 "Maintenance & repair".

WARNING

High temperature! Burning! Proceed with caution when brazing system

components. Do not touch the compressor until it has cooled down. Ensure

that other materials in the area of the compressor do not make contact.

IMPORTANT

Blockage! Compressor breakdown! Maintain a flow of oxygen-free nitrogen

through the system at very low-pressure during brazing. Nitrogen displaces

the air and prevents the formation of copper oxides in the system. If allowed

to form, the copper oxide material can later be swept through the system and

block screens such as those protecting capillary tubes, thermal expansion

valves, and accumulator oil return holes.

Contamination or moisture! Bearing failure! Do not remove the plugs until

the compressor is set into the unit. This minimises any entry of contaminants

and moisture.

Copeland Scroll compressors have copper-plated steel suction

and discharge. These tubes are far more robust and less prone

to leaks than copper tubes. Due to the different thermal

properties of steel and copper, brazing procedures may have to

be changed from those commonly used.

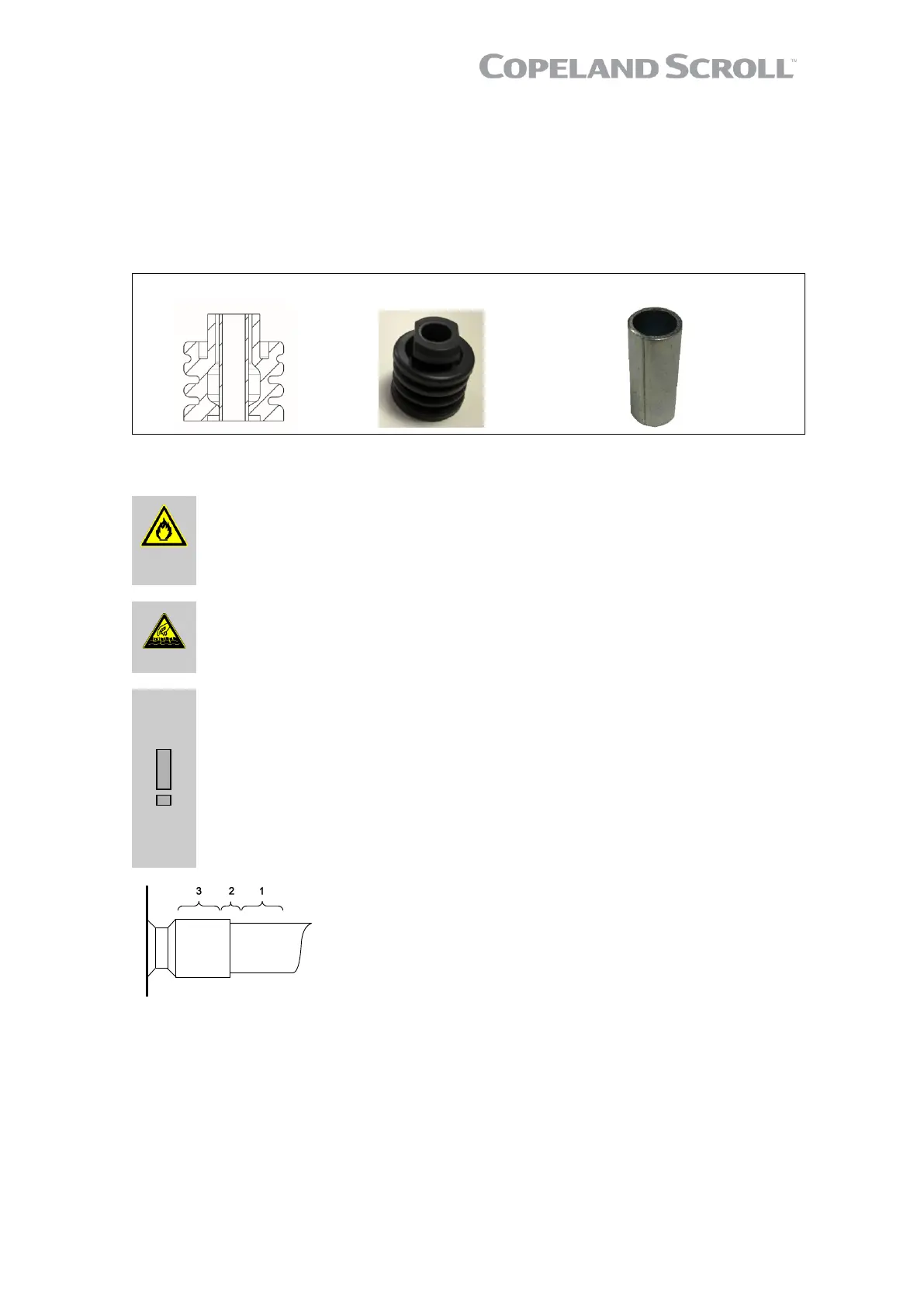

Refer to Figure 14 and procedure below for the brazing of the

suction, discharge and injection lines to a Scroll compressor.

▪ For systems with A2L refrigerants, it is mandatory to flush oxygen-free nitrogen through the

piping during the brazing process.

▪ The copper-coated steel tubes on scroll compressors can be brazed in approximately the same

manner as any copper tube.

▪ Recommended brazing materials: any silfos material is recommended, preferably with a

minimum of 5% silver. However, 0% silver is acceptable.

▪ Be sure tube fitting inner diameter and tube outer diameter are clean prior to assembly.

▪ Using a double-tipped torch, apply heat in area 1.

▪ As the tube approaches brazing temperature, move the torch flame to area 2.

Figure 14: : Brazing areas

Loading...

Loading...