7

CROSBY STYLE JOS-E, JBS-E, JLT*-JBS-E, JLT*-JOS-E VALVES

InstallatIon and MaIntenance InstructIons

5.6 Valve operation

Crosby Style JOS-E/JBS-E valves intended for

compressible fluid service and tested with air

or steam will open with a sharp clear popping

action at the set point. Valves for liquid service

tested with water are considered open when

there is a continuous unbroken stream of liquid

flowing from the valve.

5.7 Set pressure changes

Set pressure changes beyond the specified

spring range will necessitate a change in the

valve spring assembly consisting of the spring

and two fitted spring washers. The new spring

and washers must be obtained from Emerson

and the valve must be reset and the nameplate

restamped by an authorized valve repair facility.

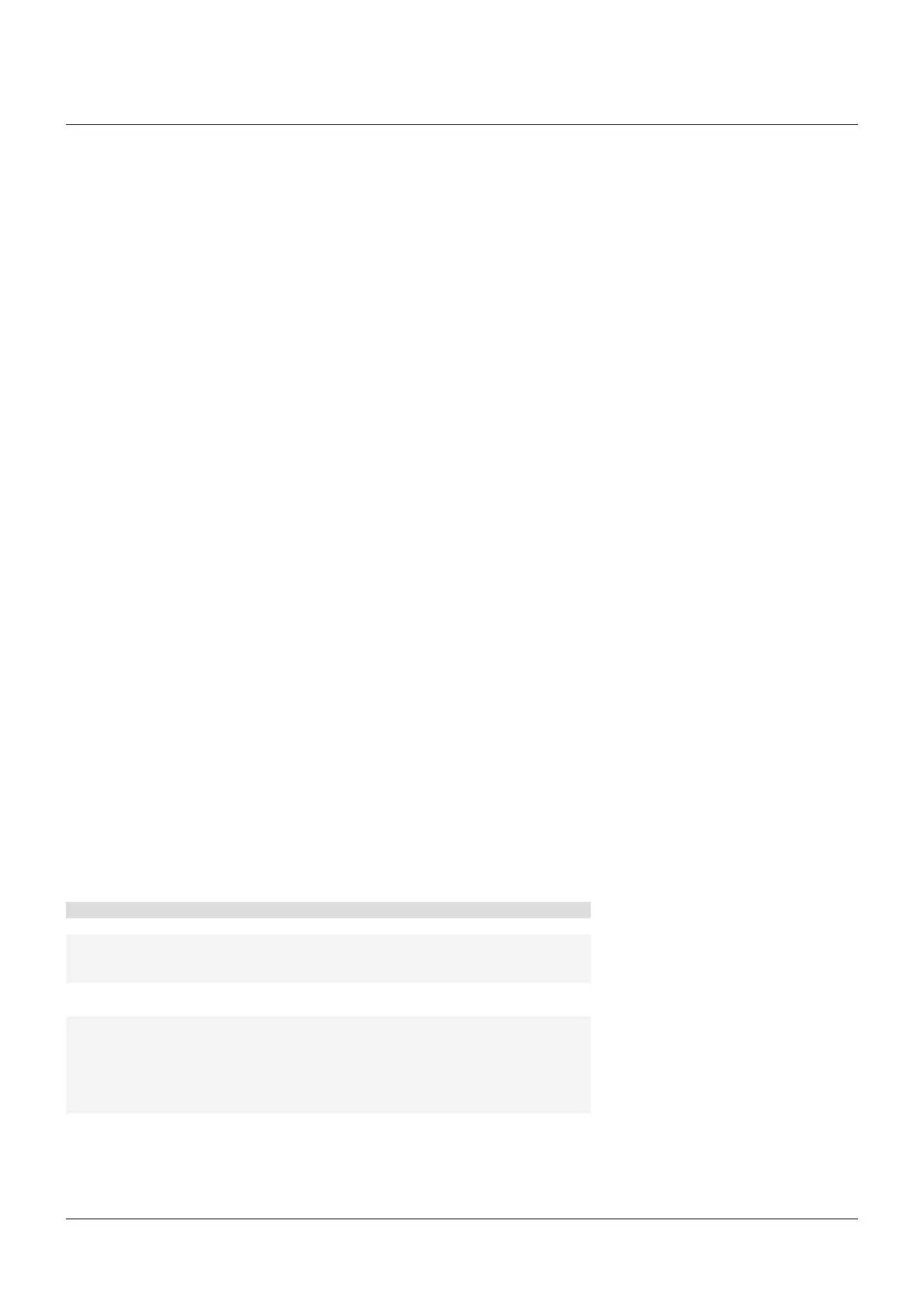

TABLE 1

Service Orifice size Nozzle ring setting (below highest lock position)

Style JOS-E/JBS-E pressure relief valve recommended nozzle ring settings

Vapor and gases

D through J -5

K through N -10

P through T -15

Style JLT-E pressure relief valve recommended nozzle ring settings

Liquids and gases

D, E, and F -2

G, H, and J -3

K and L -5

M and N -10

P and Q (see Table 2)

R and T (see Table 2)

5.8 Set pressure adjustment

Before making any adjustments, reduce the

pressure under the valve seat to at least 10%

below the stamped opening pressure. This will

prevent seat damage due to turning of the disc

on the nozzle seat and minimize the chance of

an inadvertent valve opening. A strong (high)

ring position is necessary to obtain a good clean

popping action of the valve on air or gas with

the limited volume available on the test bench.

5.8.1

(Not required for testing on liquid). Remove

the nozzle ring set screw and raise the

nozzle ring until it touches the disc holder,

then back it down two (2) notches. Exercise

care in counting the number of notches

moved so that the ring can be returned to

its proper position following testing.

Moving the notches on the nozzle ring to

the left will lower the nozzle ring.

Replace the nozzle ring set screw before

each set pressure test. The set screw

must engage one of the ring notches,

being careful that it does not bear on the

top of a tooth.

5.8.2 Remove the cap or lifting lever following

the instruction for valve disassembly

(seeparagraph 6).

5.8.3 Loosen the adjusting bolt nut and turn the

adjusting bolt clockwise to increase set

pressure or counterclockwise to reduce

set pressure.

5.8.4 Retighten the adjusting bolt nut following

each adjustment.

5.8.5 Two or three consecutive valve openings

at the same pressure are necessary to

verify the opening pressure accurately.

5.8.6 Opening pressure tolerance shall comply

with ASME Section VIII Division 1 UG-136

(d) (1) as below or other tolerance may

be used so long as they meet ASME

requirement:

The set pressure tolerance for pressure

relief valves shall not exceed ±2 psi

(15 kPa) for pressures up to and including

70 psi (500 kPa) and ±3% for pressures

above 70 psi (500 kPa)

5.8.7 Once the set pressure has been

established, lower the nozzle ring to

the installed ring position as indicated

in Table 1 and replace the nozzle ring

set screw as described above. Seal wire

the adjusting bolt and adjusting ring set

screw with identifying seals.

5.9 Nozzle ring settings

The nozzle ring adjustment is made at the

factory and resetting in service is seldom

necessary. Should it be necessary to change

blowdown or reduce valve simmer, the nozzle

ring may be adjusted as follows: (see the next

paragraph for P, Q, R and T orifice Style JLT).

CAUTION

Should any adjustments be made while the valve is

installed on a pressurized system, the valve should

be gagged while ring adjustments are made.

NOTE

Minus sign indicates number of ring notches below starting position of nozzle ring which is the highest position

with the valve closed (contact with disc holder).

Loading...

Loading...