11

September 2018

SIL Safety Manual

DOC.SILM.EF.EN Rev. 1

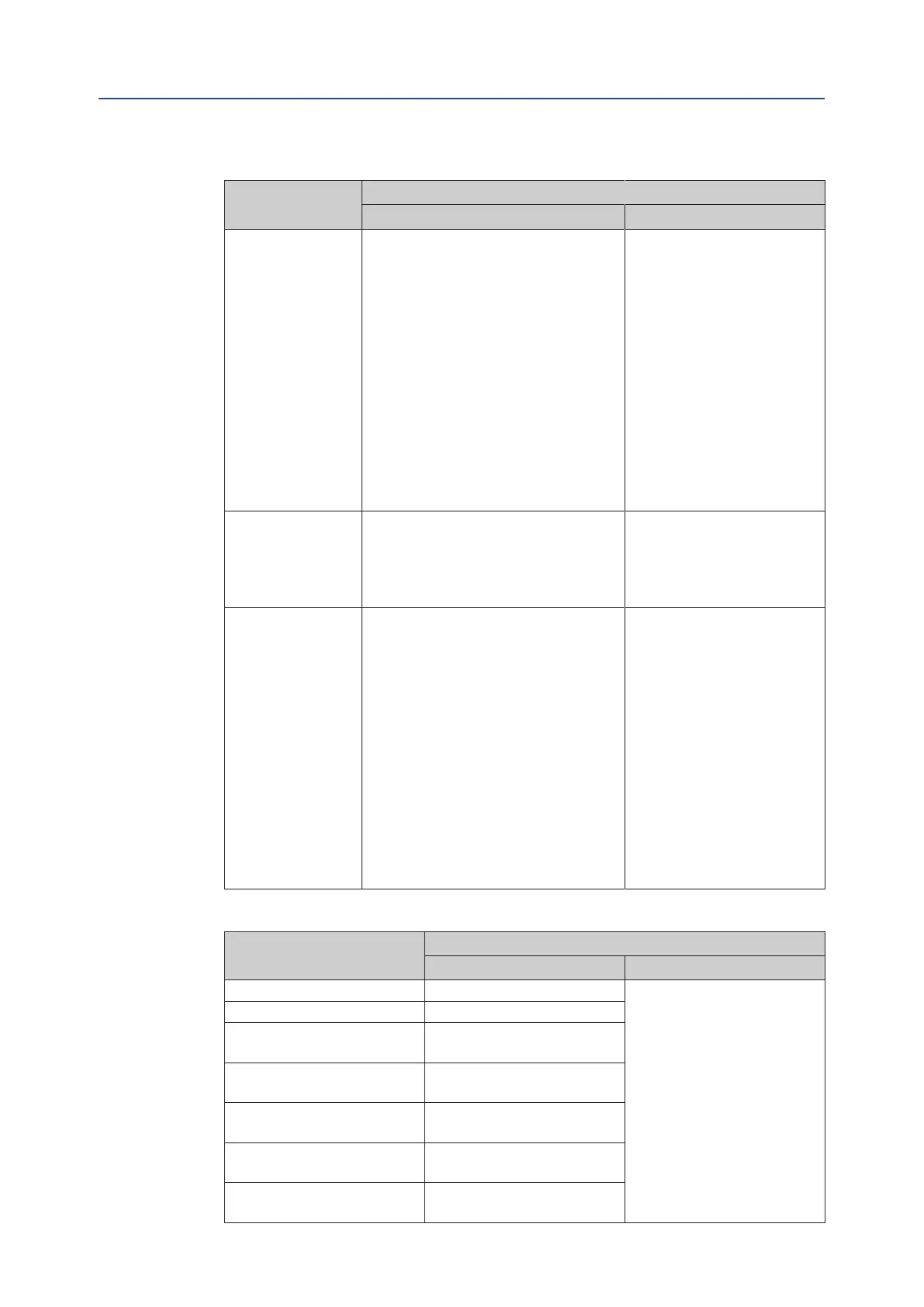

Periodic Test and Maintenance Requirements

Table 2. Instruments/equipment to be used for the test

Quantity

Instruments/equipment

Automatic Procedure Manual Procedure

Angular position of

the shaft

Case A

Use of a Logic Solver:

1. Limit switches box, or 4÷20 mA

position transmitter

2. Digital Input Module / Analog Input

Module included in the Logic Solver

3. Application Software function

(to compare the actual trend with the

one stored during SAT)

Case B

Use of a Partial stroke testing device:

1. Limit switches box, or 4÷20 mA

position transmitter

2. Partial stroke testing device with

integrated Software function

1. Limit switches box, and/or

visual indication

2. Skilled and trained

personnel

Time necessary

to reach the nal

position

As above

1. Limit switches box, and/or

visual indication

2. Chronometer

3. Skilled and trained

personnel

Output torque

(Pressure in the

cylinder)

Case A

Use of a Logic Solver:

1. Pressure transmitter connected to

the cylinder chamber

2. Analog Input Module included in

the Logic Solver

3. Application Software function

(to compare the actual trend with the

one stored during SAT)

Case B

Use of a Partial stroke testing device:

1. Pressure transmitter connected to

the cylinder chamber

2. Partial stroke testing device with inte-

grate Software function

Skilled and trained

personnel (to check audible

partial sticking)

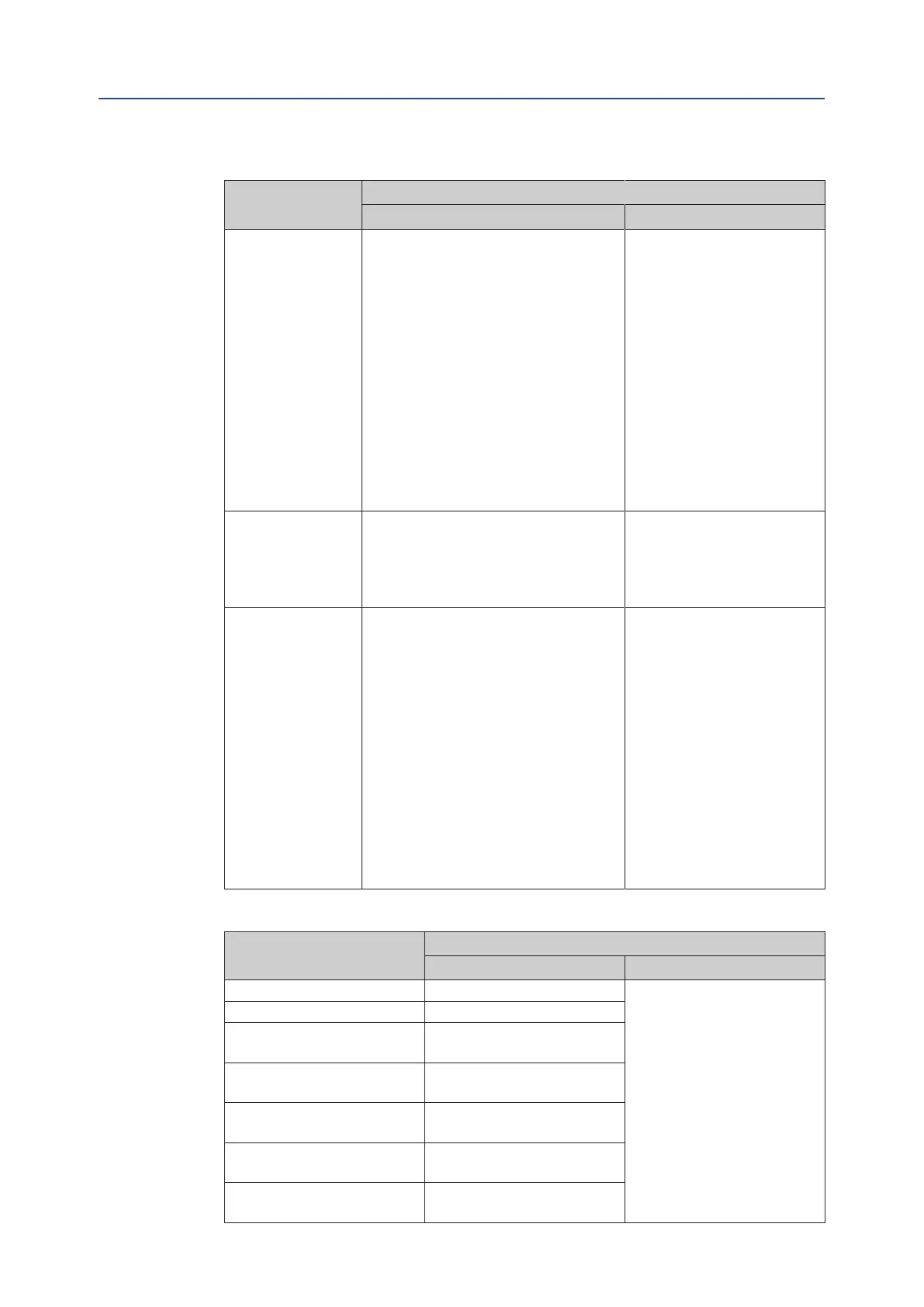

Table 3. Failure mode detectable by the test

Component

Detectable failure modes

Automatic Procedure Manual Procedure

Housing Breakage

As per automatic procedure

End cap Breakage

Piston

Breakage

Sticking

Rack

Breakage

Binding

Pinion

Breakage

Binding

Spring

Breakage

Weakened

Stroke adjustment

Breakage

Bended

Section 8: Periodic Test and Maintenance Requirements

Loading...

Loading...