2

EFFECTIVE OIL PRESSURE

Effectivenetoilpressureisthedifferencebetweentheoilpump

outletpressureandthecompressorcrankcasepressure.

EXAMPLE:

Oil Pump Outlet Pressure 40PSIG 20PSIG

Crankcase Pressure 10PSIG 8’’vacuum

Net Effective Oil Pressure 30PSIG 24PSIG

TheFD113measuresthedifferentialpressurebetweentheoil

pumpoutletpressureandthecompressorcrankcasepressure.

TheFD113–ZU/ZUKisfactorypresetto—

Pressure Energize Timer:10PSIDonfallingpressure

De–Energize Timer:15PSIDonrisingpressure

Time–Lockoutafter120secondsofenergizedtime

(ThisisCopelandfactoryspecications)

Manufacturer’s Setting Specications (Typical)

Low Event PSID

Manufacturer Time Delay(seconds)

➀

(EnergizetimeronfallingPSID)

Copeland 120 9–10*

Bitzer 90 9–10*

Carrier 45 6.5**

* Standardfactorysetting–9/10PSIDLowEvent.Noadjustmentrequired.

** Requiresadjustmentapproximately1/2turntoleftper“Checkingand

AdjustingPressure”instructions.

➀ Standardfactorysetting120seconds(Copeland).Adjustasrequiredto

othermanufacturer’sspecications.Seegure1“TimerAdjustment

Button”–Verifytimingutilizingeither“CheckingandAdjustingTimer”

procedureor“ControlCheckout/TimerCheckout”procedureandreadjust

asrequired.

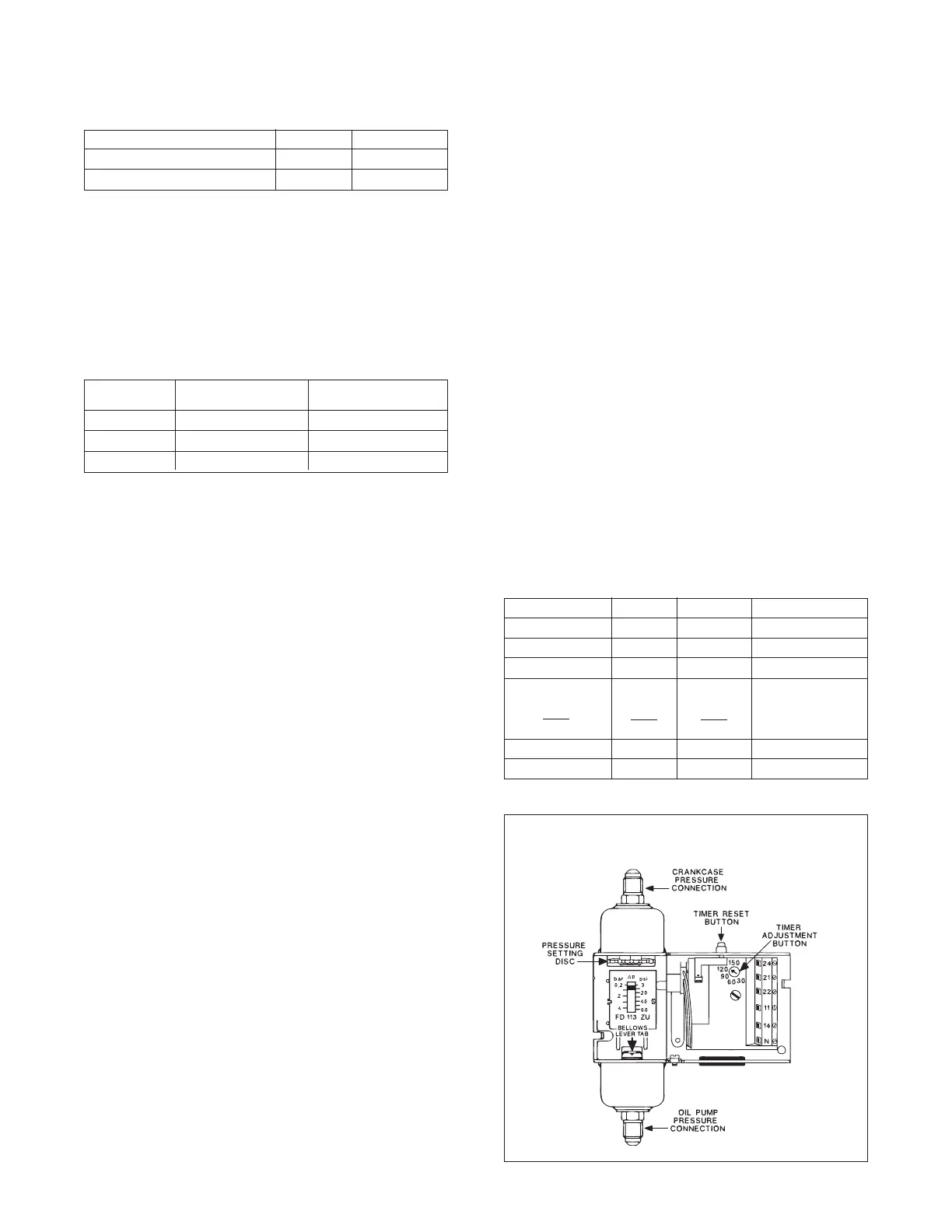

NOTE: After pressure and time settings have been made and veried, a

piece of tape should be placed over the pressure setting disc slot

and timer adjustment button to prevent tampering.

(Reference gure 1)

CONTROL CALIBRATION/ADJUSTMENT

Pressure Check—BENCH TEST NO VOLTAGE APPLIED

1) Attach“Oil”connectiontopressuresource

(100PSIGMax)withalowpressuregauge.

2) Leave“Low”connectionatatmosphericpressure

(unattached).

3) ConnectContinuityTesterbetweenterminals11

and14(safelightconnection).Nocontinuityshould

beshown.

4) Pressurizeoilconnectionto100PSIG.

Continuitylightshouldenergize.

5) Slowlydepressurize.Continuitylightshouldde-energize

atapproximately10PSIG(factory).

6) Slowlyre-pressurize.Continuitylightshouldre-energize

approximately5PSIabovede-energizepressure.

Pressure Adjustment—

1) Tochangepressureadjustmentfromfactorysetting,

removecontrolcover.Rotatenotchedpressuresetting

discinthecontrol–righttoincrease,lefttodecrease

settings(seegure1).Repeatsteps4-6todetermine

settings.Adjust/Repeatasnecessarytoobtaindesired

timerstart(minimumoilpressuresetting).Note:Control

shouldnotbesettobelowminimumeffectiveoilpressure

recommendedbythecompressormanufacturer.

CHECKING AND ADJUSTING PRESSURE

Thetimerisfactorypresetto120seconds

(CopelandSpecication).

Timer Checkout

1) RemoveJumperbetween11&22.

2) Connectacontinuitylightacrossterminals21and24.

Nocontinuityshouldbeshown(ifitdoes,press

resetbutton).

3) Withnopressuretothe“Oil”or“Low”bellows

connections,apply24to240VoltAC/DCacross

terminals11and“N”.Thetimershouldtripoutand

continuityshouldstartbetweenterminals21and24

afterapproximately120seconds.

Timer Adjustment

1) Removepowerfromterminals11and“N”.Pushreset

button,adjusttimerbuttontotimedesired.

2) Re–energizeterminals11/“N”,observetimetotrip–out

(continuitybetweenterminals21and24).

3) Repeatsteps1and2untildesiredtrip–outtimeis

obtained.NOTE:Controlshouldnotbesetbelowthe

minimumtimespeciedbythemanufacturer.

4) Removepowerandcontinuitylightandreinstall11/22

Jumper,ifrequired.

CHECKING AND ADJUSTING TIMER

Penn Ranco Robertshaw To ALCO Terminal

L L L 21

M M M 22

(Alarmwhenpresent) A S 24

V/V1 AorB

120 120 120 N

240 240 240

2 2 T2 11

None None None 14“Normal”light

Pressure Connections

1) Withthecompressordepressurized(0PSIG),connect

thebottompowerelementmarked“Oil”totheoil

pumpoutletconnection.

2) Connectthetoppowerelementmarked“Low”tothe

compressorcrankcaseconnection.

Electrical Wiring

1) WhenreplacingaRanco,Penn,orRobertshawcontrol,

usethefollowingwiringcrossreference.

FD113 INSTALLATION

ThewiringoftheFD113isillustratedingures4&5.

FIGURE 1—FD113 WITH COVER OFF

Loading...

Loading...